Road crack repairing material

A technology for repairing materials and cracks, which is applied in the field of caulking materials. It can solve problems such as the inability to keep the road surface level, the inability to maintain the filling state, and large temperature and dry shrinkage deformation. It achieves excellent anti-ultraviolet aging ability and enhances anti-stripping Effect superior in ability, absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

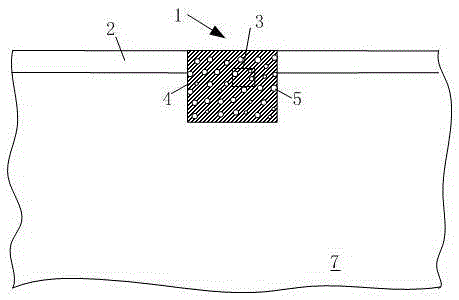

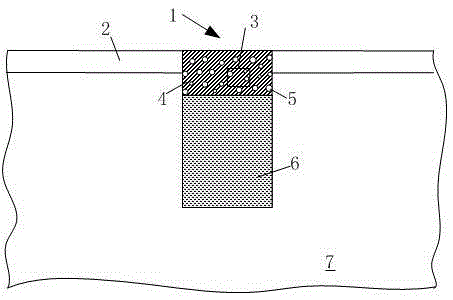

Image

Examples

Embodiment 1

[0053] A road crack repair material, comprising a grout for filling the lower part of the crack and a joint filling material for filling the upper part of the crack; the grout comprises the following components in mass fraction: 20% F-class fly ash, 60% cement kiln dust and 20% water; the joint filler includes the following components in mass fractions: 55% nano-zinc oxide-based asphalt and 45% granulated blast furnace slag powder, and the nano-zinc oxide-based asphalt contains nanometer The mass fraction of zinc oxide is 0.8%. Wherein, nano-zinc oxide is commercially available high-activity nano-zinc oxide.

[0054] The preparation method of described road crack repairing material, comprises the steps:

[0055] A. Preparation of grout

[0056] a1. Evenly mix fly ash and cement kiln dust according to the proportion;

[0057] a2. Add water in proportion and stir to obtain a paste, which is the grouting material;

[0058] B. Preparation of joint filler

[0059] b1. Base asp...

Embodiment 2

[0068] A road crack repair material, comprising a grout for filling the lower part of the crack and a joint filler for filling the upper part of the crack; the grout comprises the following components in mass fraction: 25% F-class fly ash, 50% cement kiln dust and 25% water; the joint filler includes the following components in mass fraction: 50% nano-zinc oxide-based asphalt and 50% slag powder, the nano-zinc oxide in the nano-zinc oxide-based asphalt The mass fraction is 1%.

[0069] The preparation method of described road crack repairing material, comprises the steps:

[0070] A. Preparation of grout

[0071] a1. Evenly mix fly ash and cement kiln dust according to the proportion;

[0072] a2. Add water in proportion and stir to obtain a paste, which is the grouting material;

[0073] B. Preparation of joint filler

[0074] b1. Heat the base asphalt to 150°C, add nano-zinc oxide particles in proportion, and stir for 1.5 hours at a stirring speed of 3000rpm to obtain na...

Embodiment 3

[0077] A road crack repair material, comprising grouting material for filling the lower part of the crack and joint filler for filling the upper part of the crack; the grouting material includes the following components in mass fraction: 15% fly ash, 70% cement Kiln dust and 15% water; Described joint filler comprises the component of following mass fraction: the slag powder of 60% nano-zinc oxide base asphalt and 40%, the mass fraction of nano zinc oxide in the described nano-zinc oxide base asphalt is 1.5%.

[0078] The preparation method of described road crack repairing material, comprises the steps:

[0079] A. Preparation of grout

[0080] a1. Evenly mix fly ash and cement kiln dust according to the proportion;

[0081] a2. Add water in proportion and stir to obtain a paste, which is the grouting material;

[0082] B. Preparation of joint filler

[0083] b1. Base asphalt is heated to 155°C, adding nano-zinc oxide particles in proportion, and stirring at a stirring sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com