Structure for preventing pump from being damaged by liquid freezing in pump in SCR (Selective Catalytic Reduction) system

A SCR system, anti-damage technology, applied in the direction of internal combustion piston engine, exhaust gas treatment, mechanical equipment, etc., can solve the problem of single anti-icing technology of urea metering pump, etc., to ensure the use environment, increase the expansion space, and ensure normal operation. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

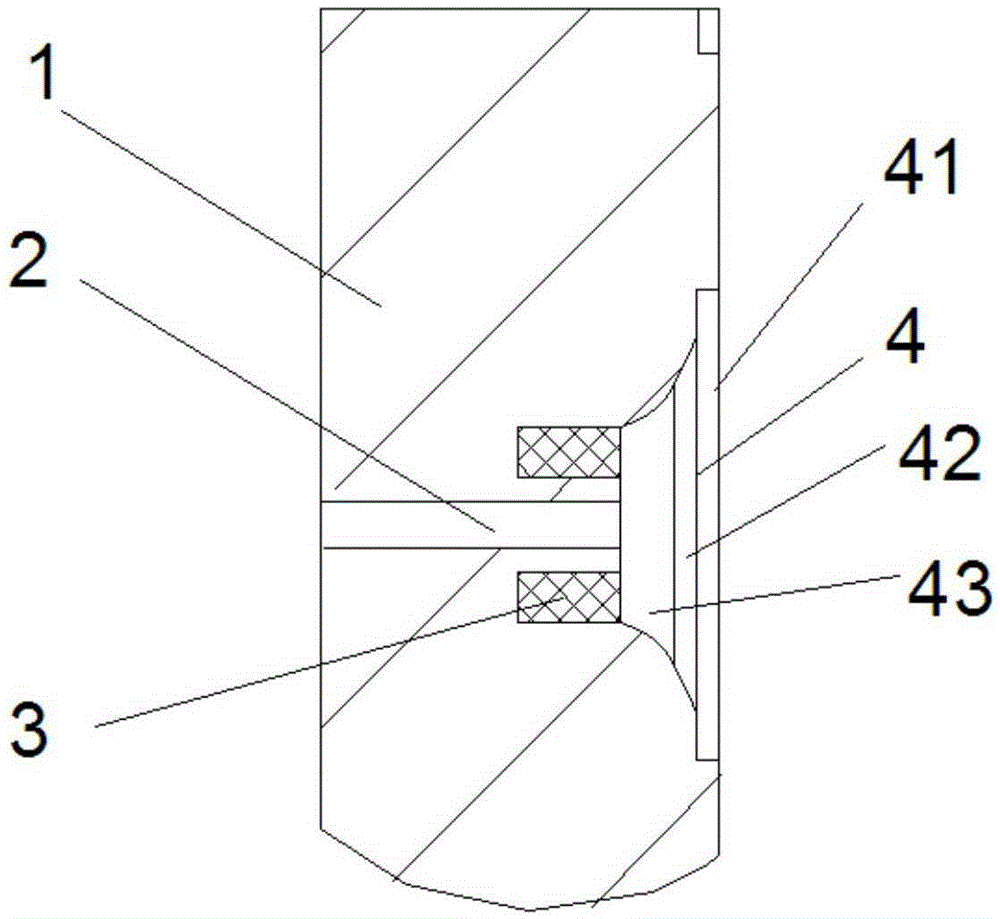

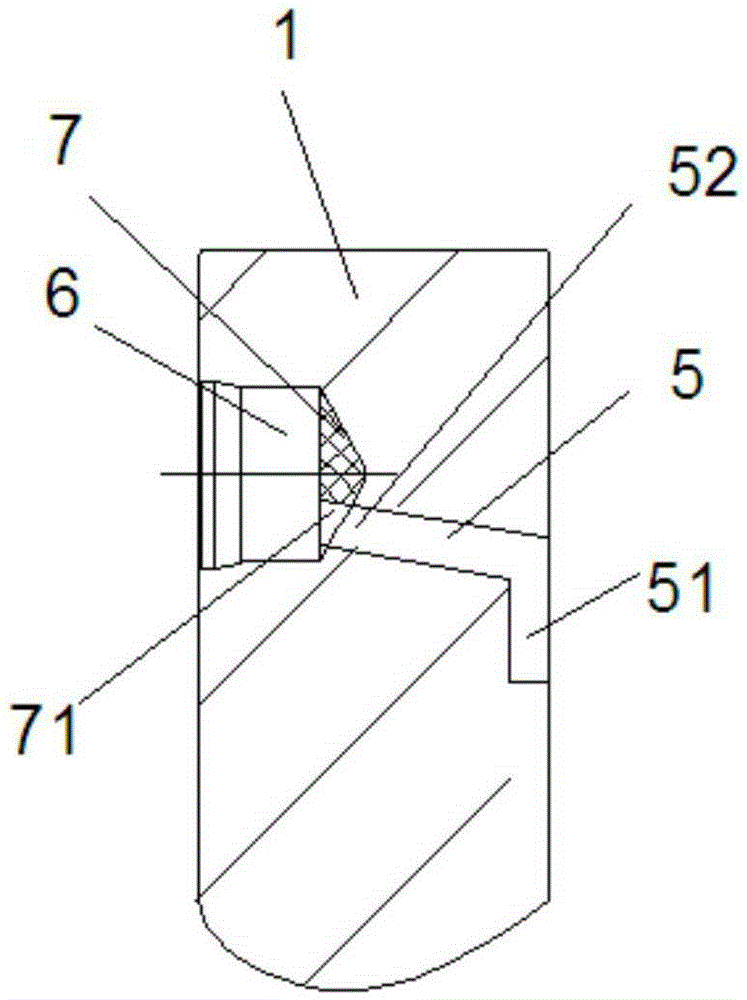

[0028] Such as Figure 1-Figure 2 As shown, a structure for preventing damage caused by freezing of liquid in the pump in an SCR system includes a pump body 1, a pressure sensor installation cavity 6 is provided on the upper part of the pump body 1, and a pressure sensor is installed inside the pump body 1 The flow channel 5, the inlet 51 of the pressure sensor inlet channel communicates with the main channel of the SCR system, the outlet 52 of the pressure sensor inlet channel communicates with the pressure sensor installation cavity 6, and the pump body 1 is also connected with the SCR system The main channel of the main channel is connected in series with a first liquid inlet channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com