Fresh air fan for heat recovery

A new fan and heat recovery technology, applied in the field of air purification, can solve the problems of poor energy saving effect and versatility, easy blockage of filters, low filtration efficiency, etc., and achieve the effects of improving fresh air quality, energy saving and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

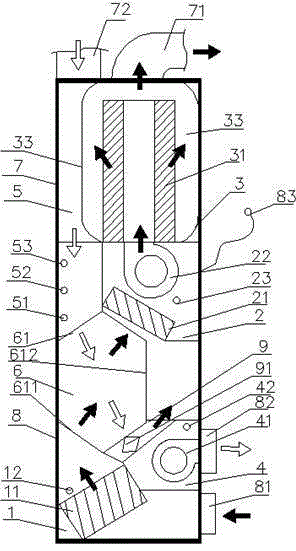

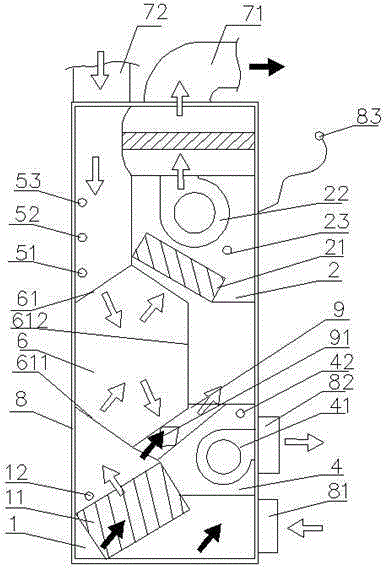

[0034] Such as figure 1 Shown: a heat recovery fresh air fan, including a box body, which is equipped with independent fresh air suction area 1, fresh air secondary filter area 2, fresh air discharge area 3, old air discharge area 4, old air suction area 5, The heat exchange area 6 and the fresh air bypass area 9; the fresh air suction area 1 has a built-in coarse-effect filter 11 for filtering outdoor air; The electrostatic precipitator 21 and the fresh air fan 22 that discharges the fresh air after the electrostatic precipitator 21 into the fresh air discharge area 3; the fresh air discharge area 3 is built-in for the fresh air discharged through the fresh air fan 22 to carry out three-stage high-efficiency filtration 31; the exhaust fan 41 built in the old air discharge area 4 for discharging the indoor old air to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com