Capacitor coupling noncontact conductance measurement device and method

A non-contact conductance and capacitive coupling technology, applied in the direction of fluid resistance measurement, material resistance, etc., can solve problems such as instability and complex structure, achieve stable performance, expand the measurement range, and simplify the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

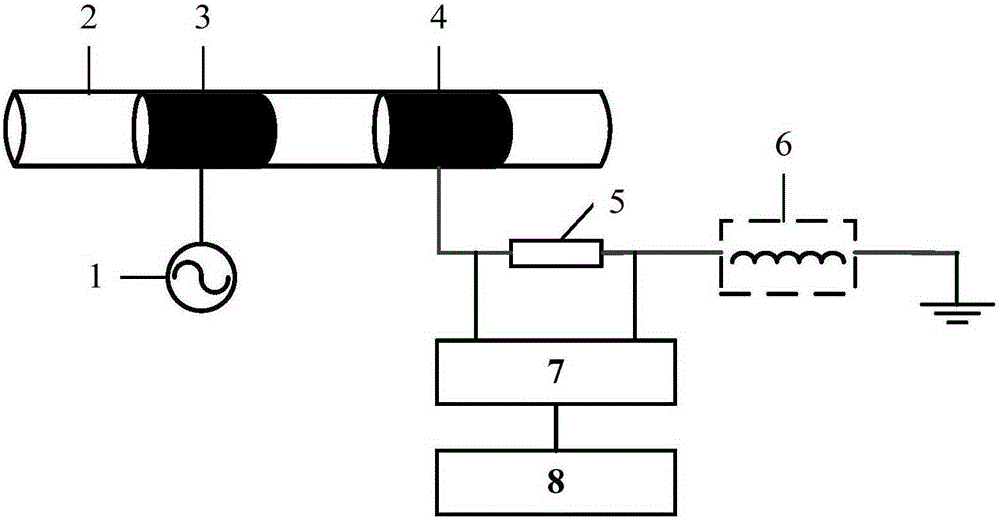

[0027] Such as figure 1 As shown, a capacitively coupled non-contact conductivity measurement device is characterized in that it includes an AC excitation source 1, an insulating measurement pipeline 2, an excitation electrode 3, a detection electrode 4, a range resistance 5, a virtual inductance 6, a differential amplification module 7, and a signal The processing module 8; the excitation electrode 3 and the detection electrode 4 are installed on the outer wall of the insulating measurement pipeline 2, the AC excitation source 1 is connected to the excitation electrode 3, the detection electrode 4, the range resistance 5, and the virtual inductance 6 are connected in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com