PMMA light guide plate with double-sided dotted microstructures

A microstructure and light guide plate technology, applied in the field of optical components, can solve problems such as unqualified processing, affecting product quality, and difficult processing, so as to ensure reflectivity and scattering rate, improve space utilization, and improve light guide uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

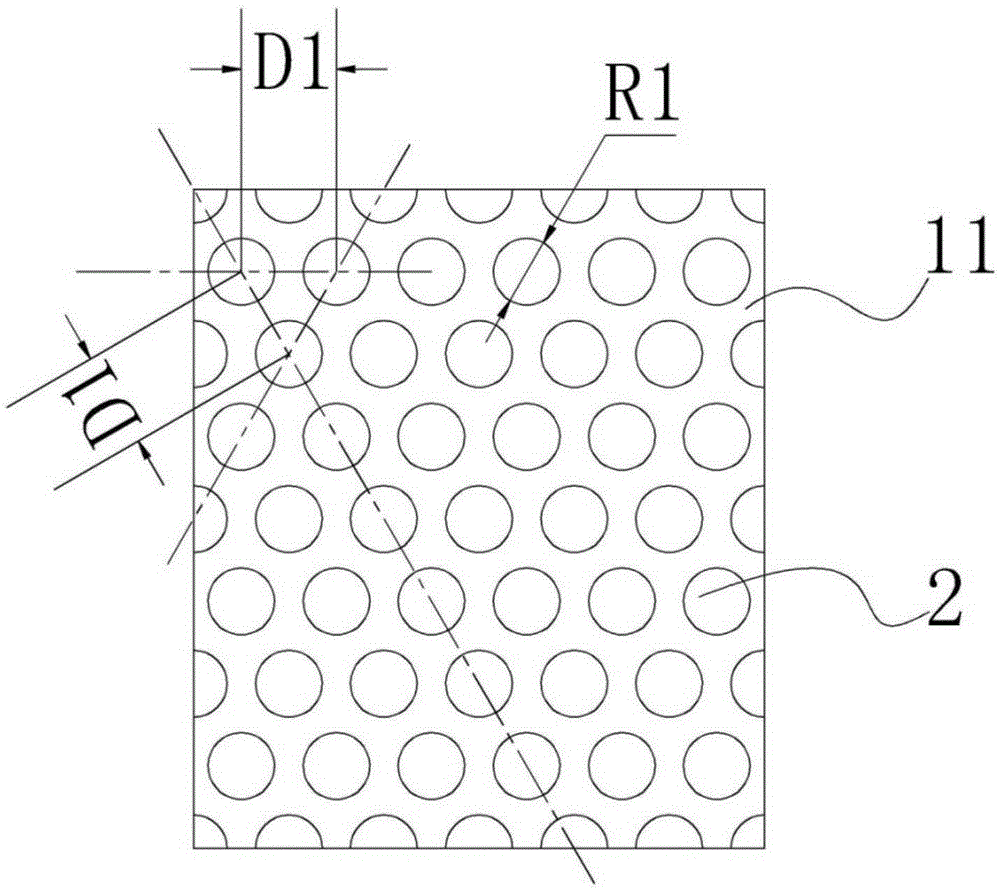

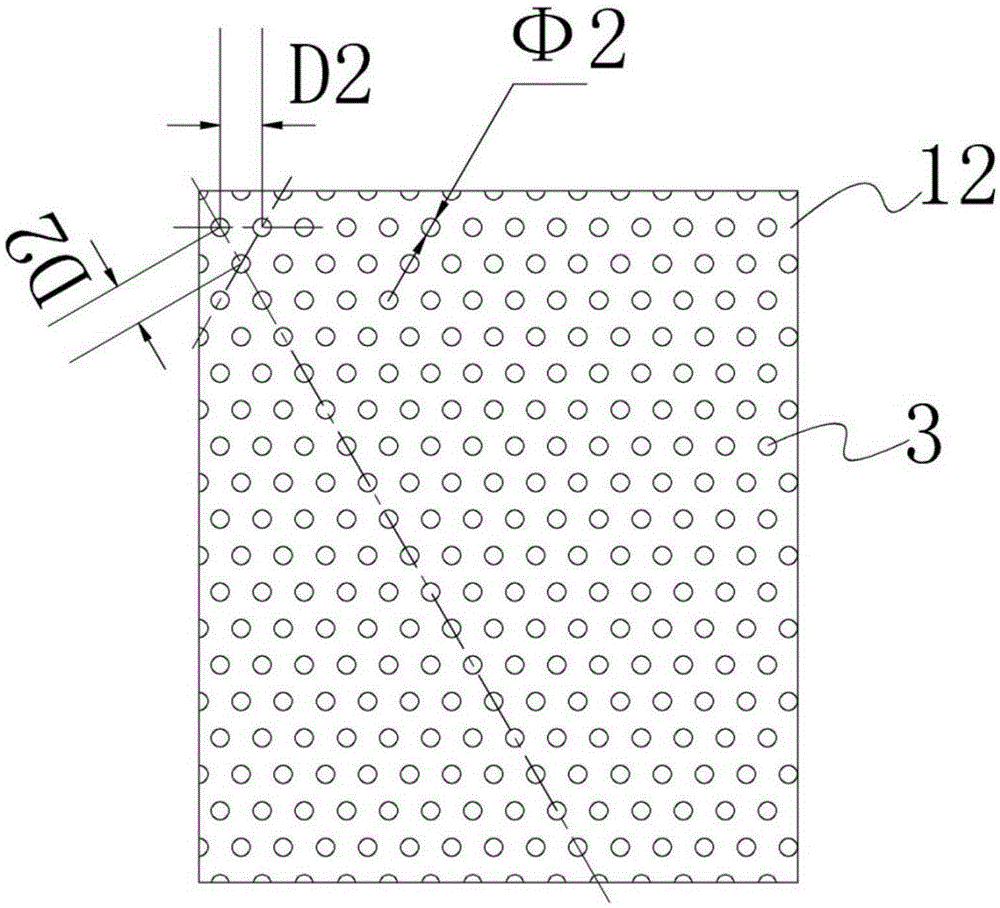

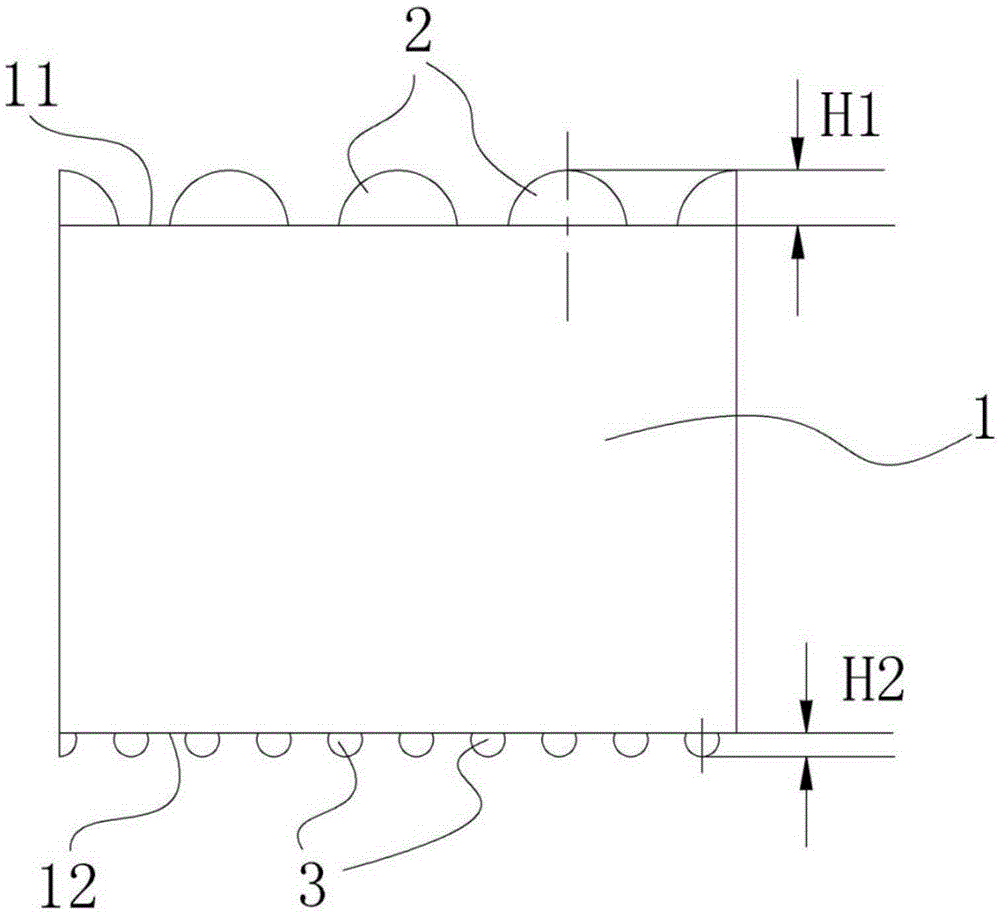

[0023] like Figure 1-Figure 3 As shown, the present invention includes a transparent plate body 1 made of PMMA, and the transparent plate body 1 has a light-emitting surface 12 for emitting light and a reflective surface 11 opposite to the light-emitting surface 12;

[0024] like figure 1 and image 3 As shown, the reflective surface 11 is provided with a plurality of reflective protrusions 2 in a spherical crown and arranged in a quincunx shape. This quincunx distribution is more uniform than the traditional row and column distribution, which improves the space utilization of the reflective surface 11 and improves The reflectivity of the light on the reflective surface 11 is improved; the reflective protrusion is made of PMMA material and integrally formed with the transparent plate body 1, thereby avoiding the reflection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com