Electrochemical battery and preparation method thereof

An electrochemical and battery technology, applied in the field of electrochemical batteries, to achieve the effect of solving the drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

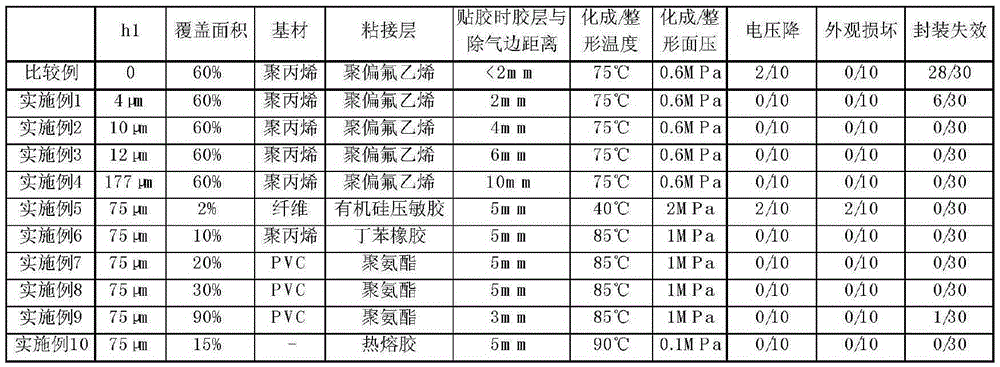

Embodiment 1

[0034] Embodiment 1, different from the comparative example, the present embodiment comprises the following steps:

[0035] Adhesive layer setting: choose polypropylene as the base material and polyvinylidene fluoride as the adhesive tape, and paste it on the surface of the bare cell. The distance between the adhesive area and the degassing packaging surface is 2mm. A layer of yellow glue with a thickness of 4 μm is arranged between the sides of the degassing package, and the yellow tape is parallel to the side of the degassing package and runs through the entire bare cell; the adhesive layer covers 60% of the surface area of the bare cell, and then the bare cell Put it in an aluminum-plastic film packaging bag for top sealing and side sealing;

[0036] The rest are the same as those of the comparative example, and will not be repeated here.

Embodiment 2

[0037] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0038] Adhesive layer setting: select polypropylene as the base material and polyvinylidene fluoride as the adhesive tape, and paste it on the surface of the bare cell. The distance between the adhesive area and the degassing packaging surface is 4mm. A layer of green adhesive with a thickness of 10 μm is arranged between the sides of the degassing package, and the green tape is parallel to the side of the degassing package and runs through the entire bare cell; the adhesive layer covers 60% of the surface area of the bare cell, and then the bare cell Put it in an aluminum-plastic film packaging bag for top sealing and side sealing;

[0039] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0040] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0041] Adhesive layer setting: select polypropylene as the base material and polyvinylidene fluoride as the adhesive tape, paste it on the surface of the bare cell, the distance between the adhesive area and the degassing packaging surface is 6mm, and then connect A layer of isolation film with a thickness of 12 μm is arranged between the sides of the degassing package, and the isolation film is parallel to the side of the degassing package and runs through the entire bare cell; the adhesive layer covers 60% of the surface area of the bare cell, and then the bare cell Put it in an aluminum-plastic film packaging bag for top sealing and side sealing;

[0042] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com