Analytical method of desulfurization efficiency influence factors in flue gas desulphurization system

A technology of desulfurization efficiency and influencing factors. It is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve problems such as difficulty in reflecting and simulating flue gas desulfurization systems, providing evidence, and complexity. The effect of shortening analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail with reference to the accompanying drawings and specific embodiments.

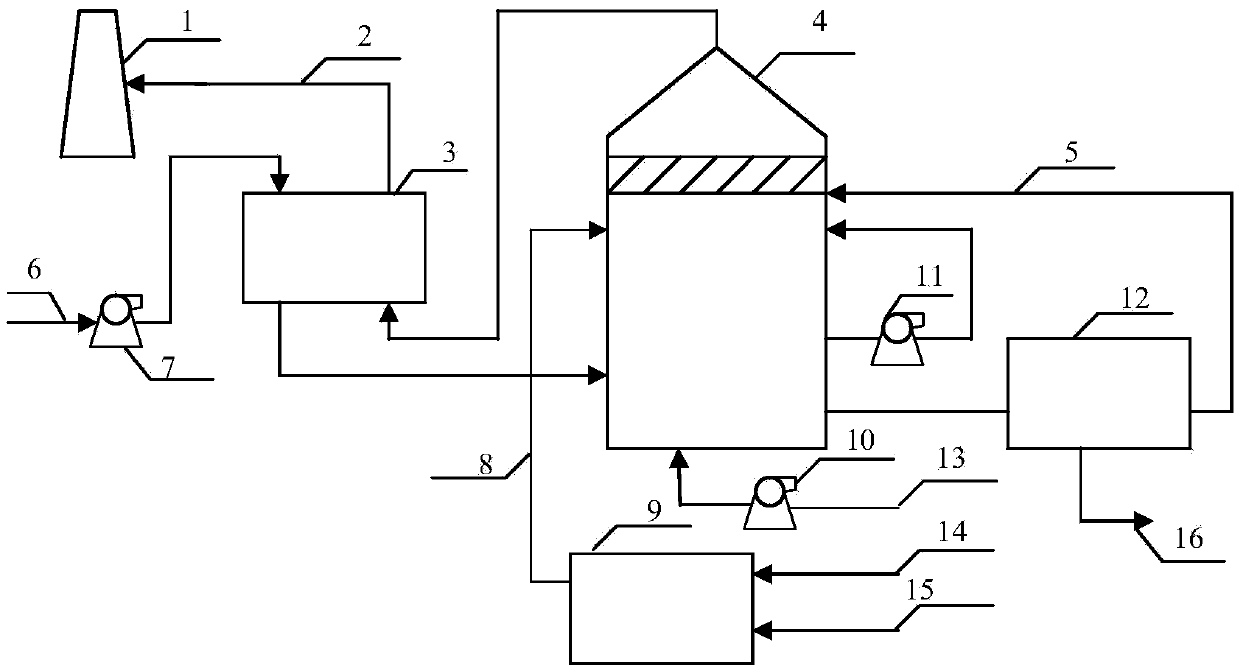

[0026] Such as figure 1 As shown, the flue gas desulfurization system in the coal-fired power plant involved in the present invention mainly includes a flue gas heat exchange system, a sulfur dioxide absorption system, a slurry preparation system and a gypsum dehydration system. The flue gas heat exchange system realizes the cooling treatment of the raw flue gas 6 and the heating treatment of the clean flue gas 2 through the heat exchanger 3. The cooled raw flue gas 6 is pressurized by the booster fan 7 and then enters the sulfur dioxide absorption system. The flue gas 2 is discharged into the atmosphere through the chimney 1. The role of the absorbent preparation system is to generate and store the absorbent 8, which is produced by mixing and stirring the industrial water 14 and the limestone mixture 15. The sulfur dioxide absorption syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com