Automobile spare part cleaning system realizing smart production

A cleaning system and auto parts technology, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of difficult to effectively remove residual sand and oil stains, waste of water resources, and poor cleaning quality Good and other problems, to achieve the effect of good cleaning quality, water saving, scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

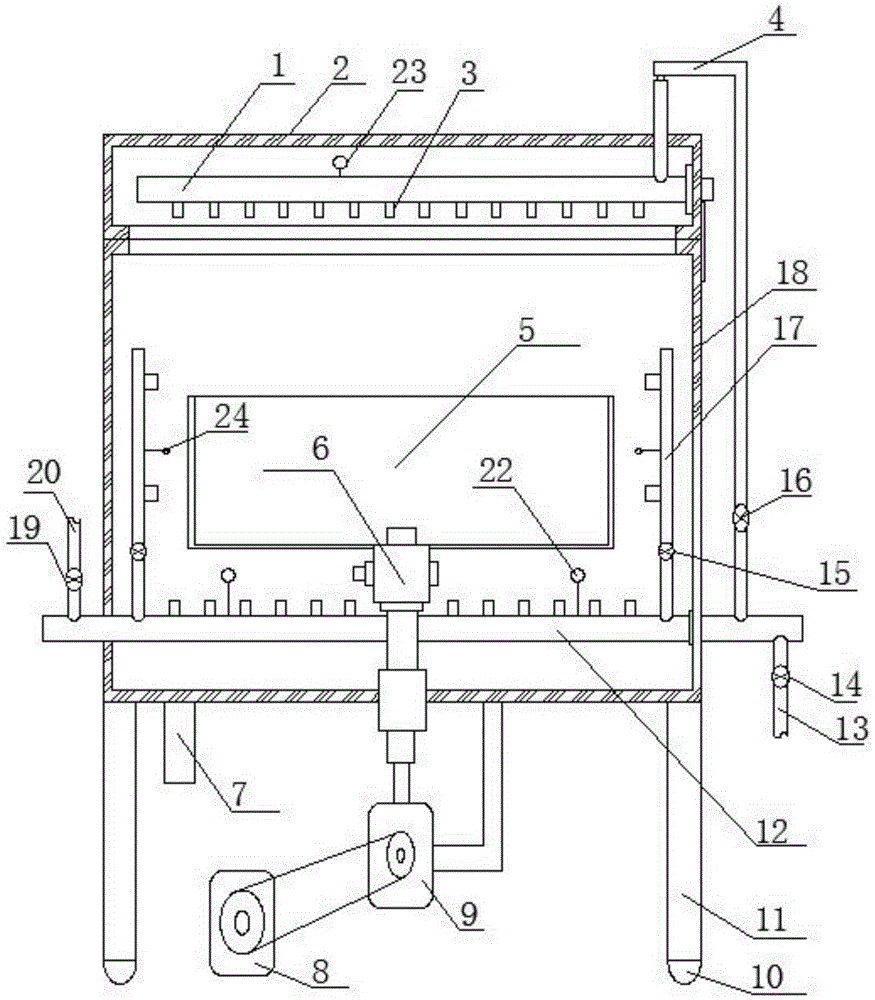

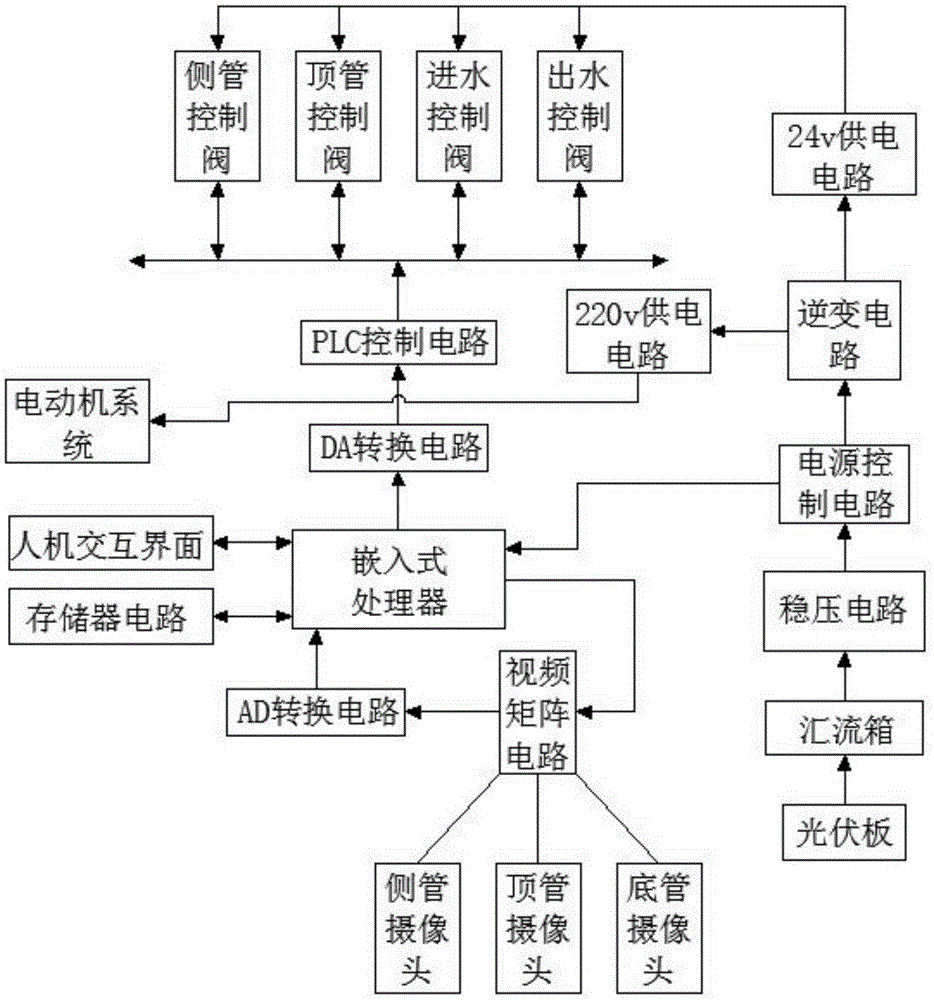

[0027] An intelligently produced auto parts cleaning system, such as figure 1 , figure 2 As shown, the following structure is specially set up: including a cleaning device, a power supply system and an intelligent control system connected with the cleaning device and the power supply system, and the intelligent control system is provided with an embedded processor, a video matrix circuit, and an AD conversion circuit. , DA conversion circuit, PLC control circuit, camera group, described embedded processor is connected with AD conversion circuit, video matrix circuit, DA conversion circuit respectively, and described video matrix circuit is connected with AD conversion circuit, and described video matrix circuit It is connected to the camera group, the DA conversion circuit is connected to the PLC control circuit, and the PLC control circuit is connected to the cleaning device; the power supply system is provided with a photovoltaic panel, a combiner box, a voltage stabilizing...

Embodiment 2

[0031] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 , figure 2As shown, the following structure is particularly arranged: the cleaning device includes a box body 18 and a box cover 2, and the box cover 2 is hinged on the upper opening end of the box body 18; a storage board is arranged in the box body 18 5, and the storage board 5 is arranged on the rotating shaft system 6; a bottom spray main pipe 12 is also provided below the storage board 5, and the bottom spray main pipe 12 runs through the box body 18, and the bottom spray nozzles at both ends of the box body 18 are exposed. The main pipe 12 is respectively provided with a water inlet system and a water outlet system; The shower branch pipe 17 is provided with a plurality of spray branch pipes 3 vertically downward on the bottom spray main pipe 12, and a plurality of spray branch pipes 3 are also arranged horizonta...

Embodiment 3

[0034] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 , figure 2 As shown, the following structure is particularly arranged: the top spray main pipe 1 is also provided on the top spray main pipe 1, and a plurality of spray branch pipes 3 are also arranged on the top spray main pipe 1, and the tank cover 2 is closed In the case of the box body 18, the water outlet of the spray branch pipe 3 on the top spray main pipe 1 is downward; the camera group is also provided with a pipe top camera 23, and the pipe top camera 23 is arranged on the top spray main pipe 1 , the top spray main pipe 1 is connected to the bottom spray main pipe 12 through the water diversion pipe 4, and the pipe jacking control valve 16 is arranged on the water diversion pipe 4, and the pipe jacking control valve 16 is respectively connected with the PLC control circuit and the 24v power supply circuit The 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com