Mechanical arm motion trail adjusting system and method

A technology of motion track and adjustment system, which is applied in the field of weld seam tracking, and can solve problems such as complicated programming, difficult welding, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

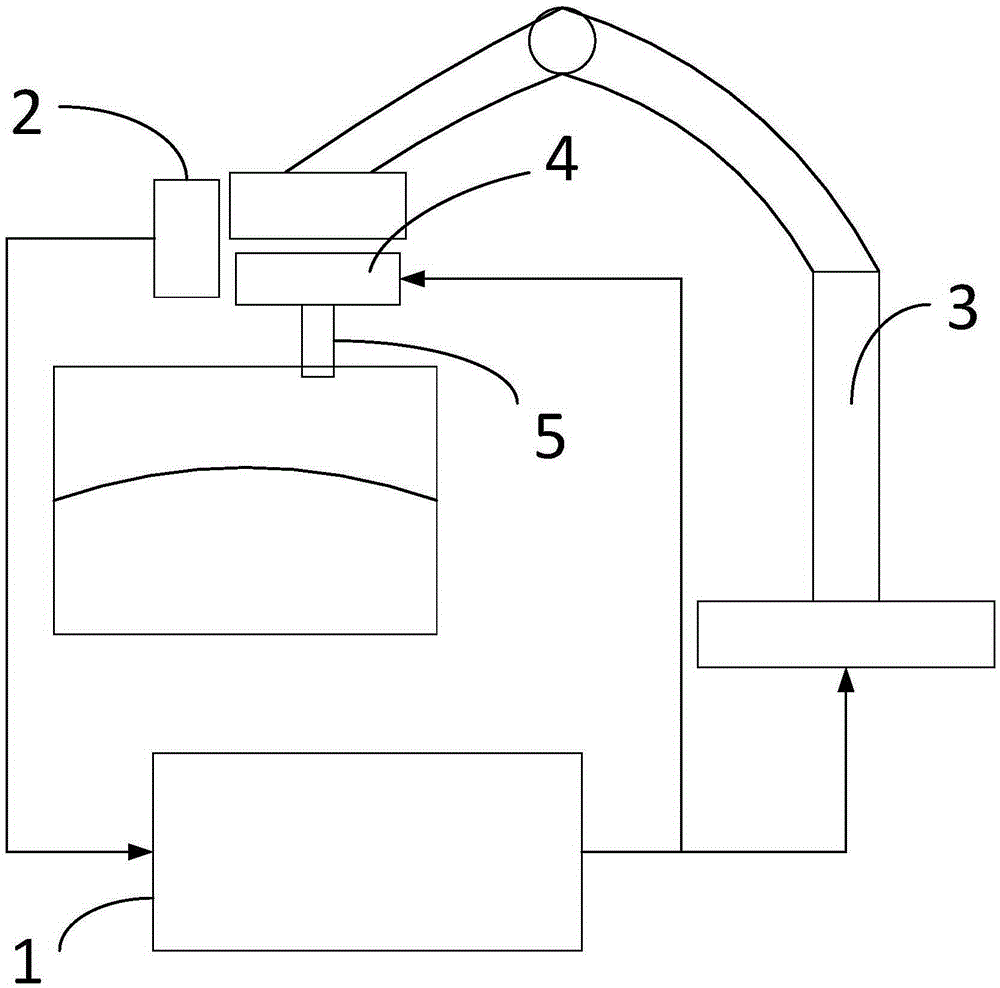

Examples

Embodiment 1

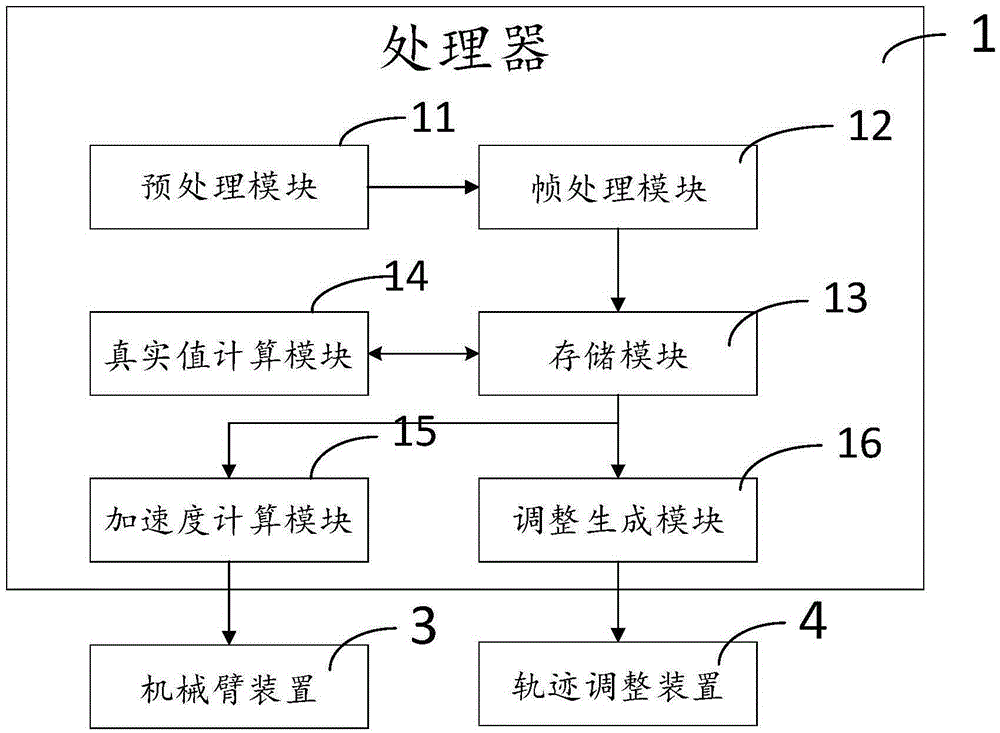

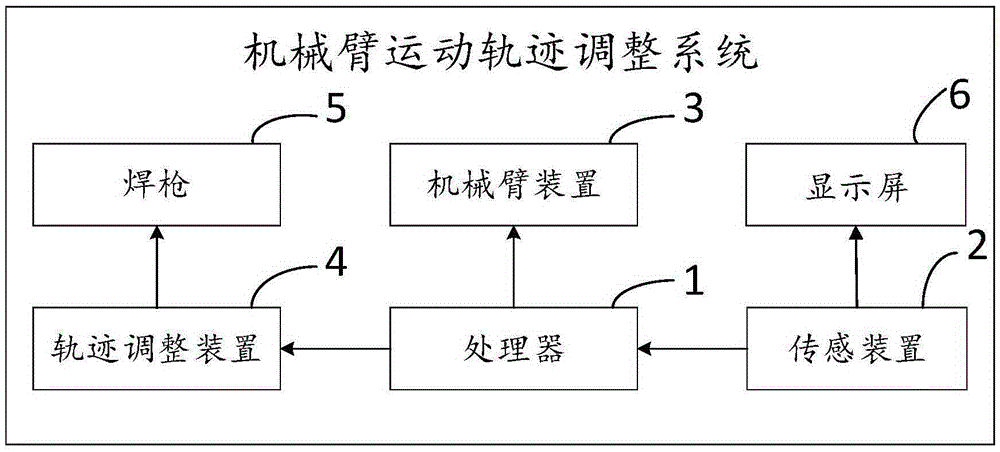

[0064] As described above, the motion track adjustment system of the mechanical arm, the present embodiment differs from it in that, as figure 2 As shown in the structure diagram of the processor of the robot arm motion track adjustment system of the present invention, the processor 1 includes: a preprocessing module 11, a frame processing module 12, a storage module 13, a real value calculation module 14, an acceleration calculation module 15 and an adjustment generation Module 16; the pre-processing module 11 receives the video image data, and sharpens each frame of image; the frame processing module 12 processes each frame of image after sharpening, and obtains the position of each position and the welding head of the welding torch 5 The measured value is also stored in the storage module 13; the real value calculation module 14 reads the measured value of the same position in different frame images from the storage module 13, calculates the real value of the position and s...

Embodiment 2

[0068] As described above, the motion trajectory adjustment system of the manipulator, the present embodiment is different from it in that the calculation formula of the real value calculation module 14 for the same position real value is:

[0069] Z = Σ i = 1 n B i Z i Σ i = 1 n B i

[0070] Among them, B i Determined by the following formula:

[0071] A i = Σ j = 1 n ...

Embodiment 3

[0079]As described above, the motion trajectory adjustment system of the manipulator, the present embodiment is different from it in that the formula for calculating the acceleration by the acceleration calculation module 15 is:

[0080] α i - = min { min s ≤ k i ( a i k ) , a }

[0081] Among them, a ik Determined by the following formula:

[0082] a i k = v i 2 - v k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com