Die pressing method of film circuit board

A circuit board and molding technology, which is applied in the field of film circuit board molding, can solve the problems of affecting film printing efficiency, cumbersome handling of plastic films, and difficulty in meeting process requirements, etc., and achieves small film deformation, high production efficiency, and good flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

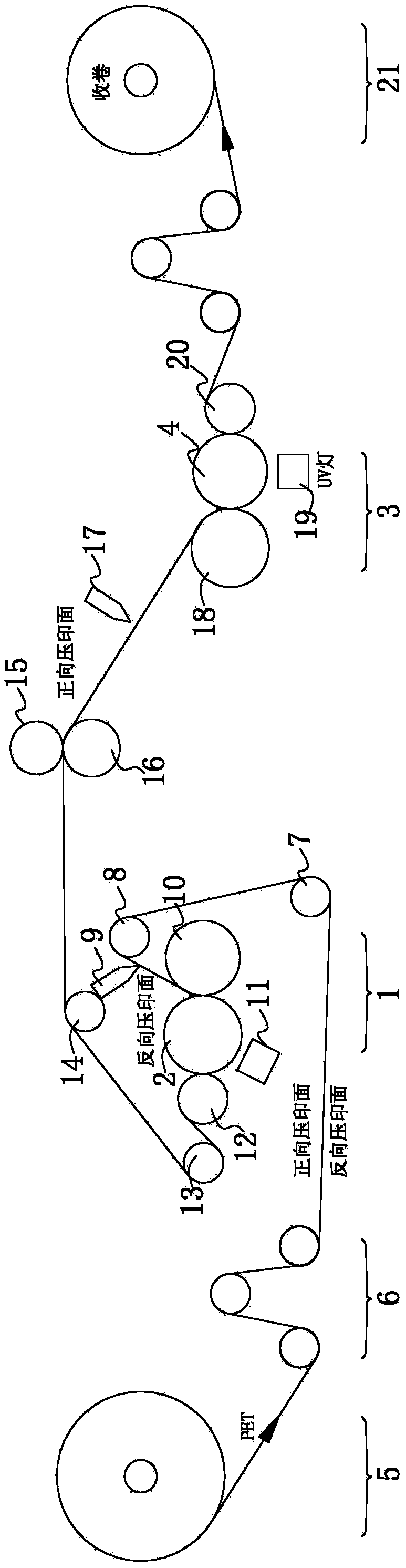

Embodiment 1

[0032] Taking the molded double-sided coated PET film as an example, in this embodiment 1, the positive embossing surface and the reverse embossing surface of the PET film are coated with a printing layer, and the printing layer is used to increase the UV coating and the PET film. The adhesion between the printing layer itself has no imaging function. The specific process of molding is as follows:

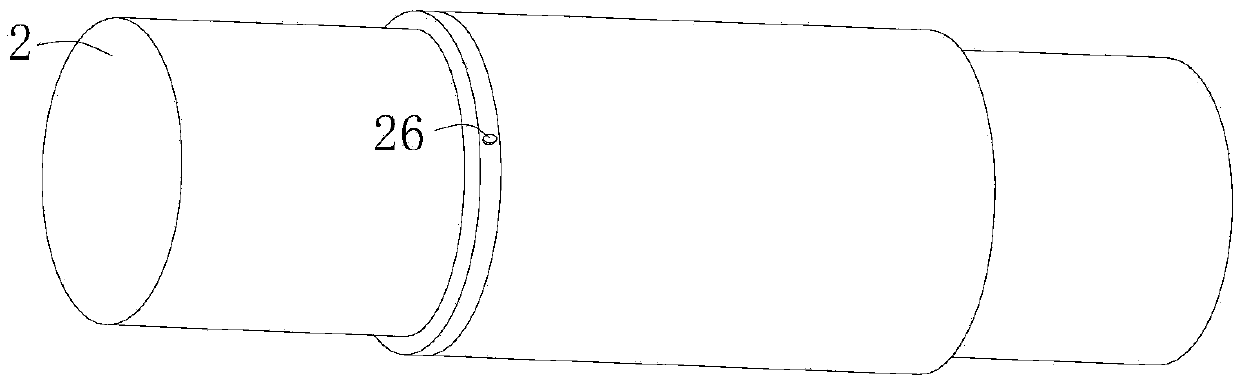

[0033] A) Use 3M strong double-sided adhesive tape to roll and paste a holographic metal nickel plate on the first plate roller 2 of the front UV molding system 1; the metal optical nickel plate is engraved with optical microstructures;

[0034] B) Use 3M strong double-sided adhesive tape to roll and stick a metal optical nickel plate on the second version roller 4 of the post-UV molding system 3, and the metal optical nickel plate is also engraved with optical microstructures;

[0035] C) according to the optical microstructure size on the metal optical nickel plate, such as the ...

Embodiment 2

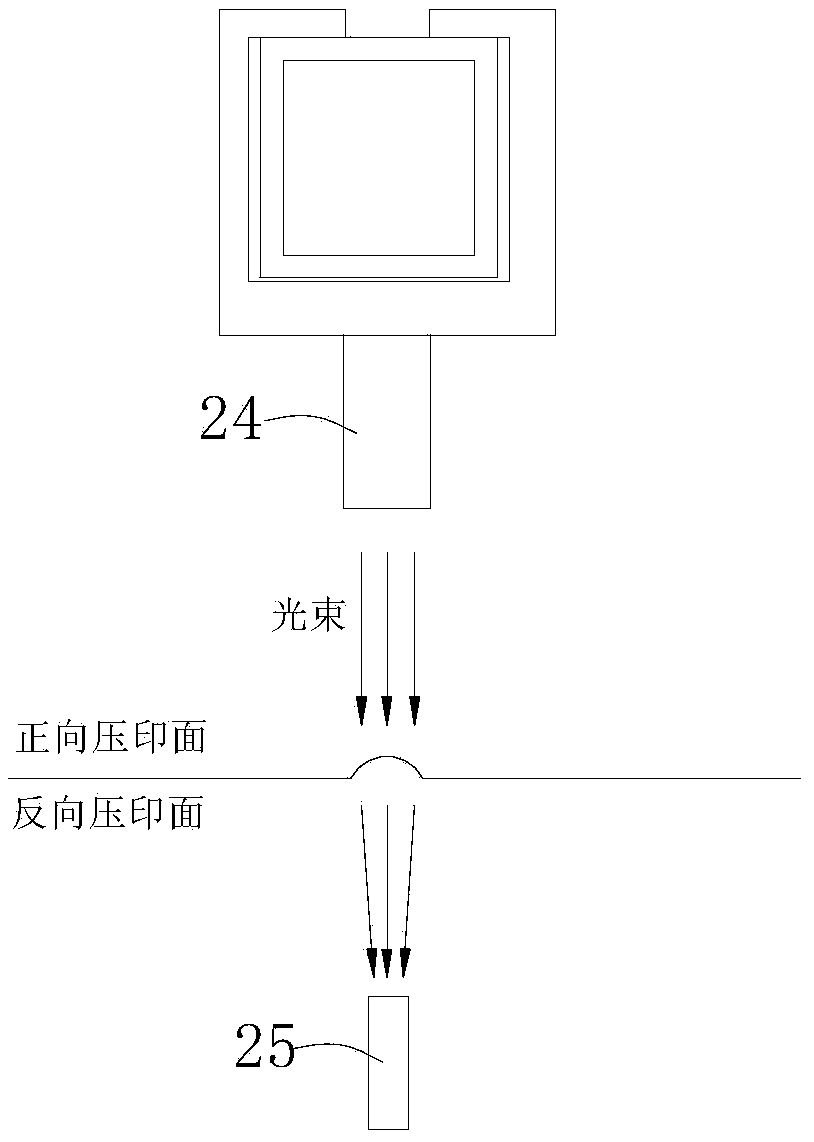

[0046] The difference between this embodiment 2 and embodiment 1 is that in this embodiment 2, the molding press used for molding the film also includes an adjustment system, which includes a positioning adjustment roller 22, a hydraulic cylinder 23, a detection light source 24 and A detection light source receiving device corresponding to the detection light source 24 ; the hydraulic cylinder 23 is used as a driving device, and its piston rod is connected with the positioning adjustment roller 22 . The detection light source receiving device includes a receiving probe 25 and a computer system, and the receiving probe 25 is data connected with the computer system; the hydraulic cylinder 23 is also data connected with the computer system through electronic components.

[0047] In the present embodiment 2, the molding process is as follows:

[0048] A) Utilize 3M strong double-sided adhesive tape to roll and stick metal optical nickel plate on the first version of roller 2, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com