Coal slime spiral conveying screen dehydration continuous system

A technology of screw conveying and screw conveyor, which is applied in the field of continuous dehydration system of coal slime screw conveying screen, can solve the problems of long working cycle, high operation requirements and low work efficiency, and achieves improved efficiency, continuous operation, and lightening Effects of Work Intensity and Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

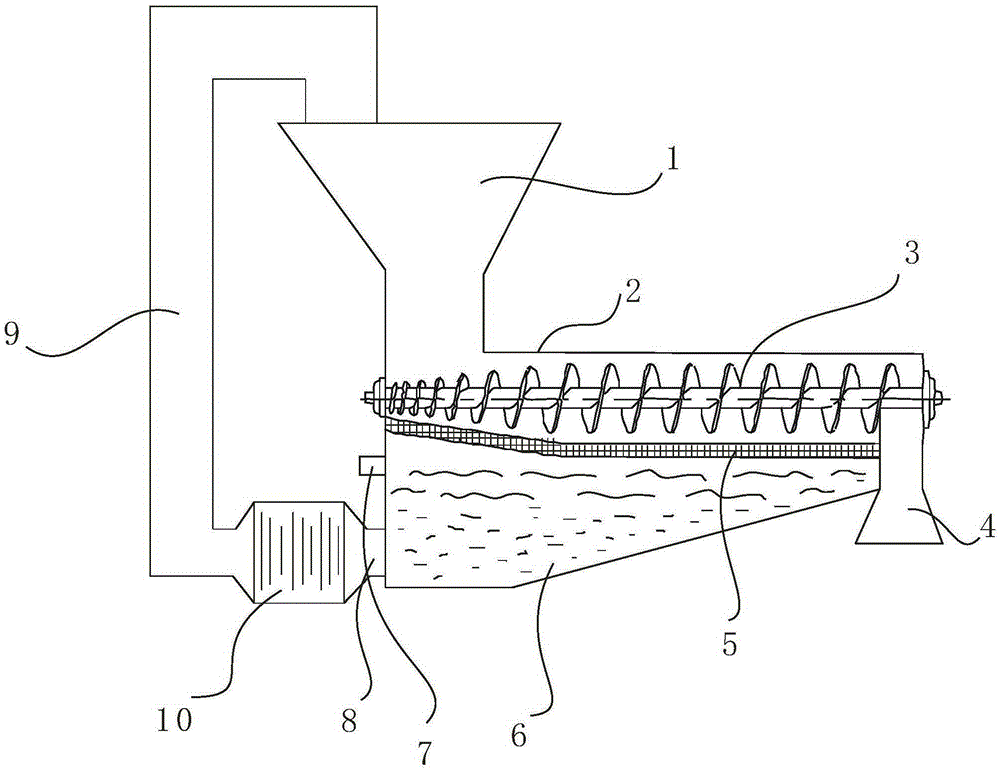

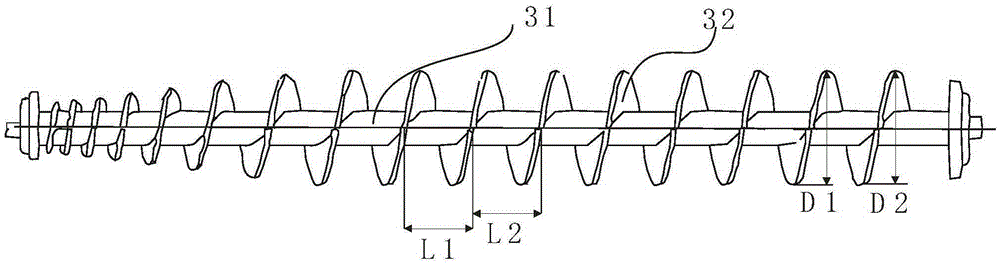

[0017] Such as figure 1 Shown is a coal slime screw conveying screen dehydration continuous system, including a screw conveyor 3; a lower hopper 1 is arranged above the feed end of the screw conveyor 3, and a discharge hopper is arranged below the discharge end of the screw conveyor 3. Port 4; screw rod 31 and screw blade 32 are installed inside the screw conveyor 3; an upper shell 2 and a lower shell 5 are arranged outside the screw conveyor 3; the lower shell 5 is a screen capable of filtering moisture .

[0018] The lower part of the screen is provided with a settling water collection box 6 for collecting and dehydrating the screen, and the small particles of coal slime in the coal slime will also fall into the settling water collection box 6 through the screen along with the moisture. Since the density of the coal slime is greater than that of water, there will be obvious stratification after standing for a period of time. In order to separate the coal slime from the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com