Glass annealing method and application thereof

A glass and annealing technology, which is applied to the glass annealing method and its application field of float production, and can solve the problems of low strength and uneven glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

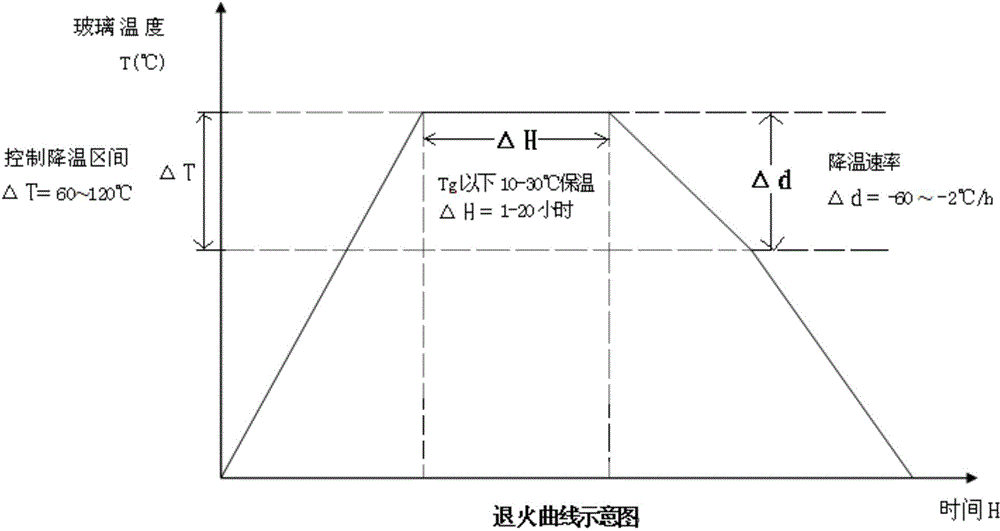

Method used

Image

Examples

Embodiment 2

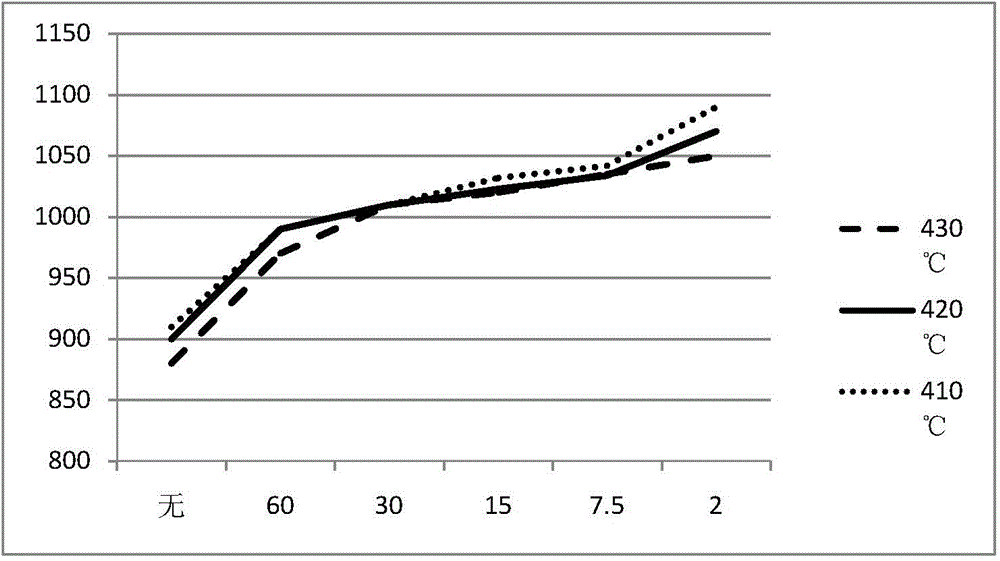

[0047] In Example 2, the tempering stress values obtained at different tempering temperatures are different. Generally speaking, within the same tempering time, the higher the tempering temperature, the deeper the stress layer of the glass and the lower the stress value. The dispersion of the stress value after glass tempering has no obvious relationship with the tempering temperature of the glass. Generally, the tempering temperature of glass suitable for chemical tempering has a relatively wide range, and tempered glass that meets the tempering performance can be obtained with the tempering time.

Embodiment 3

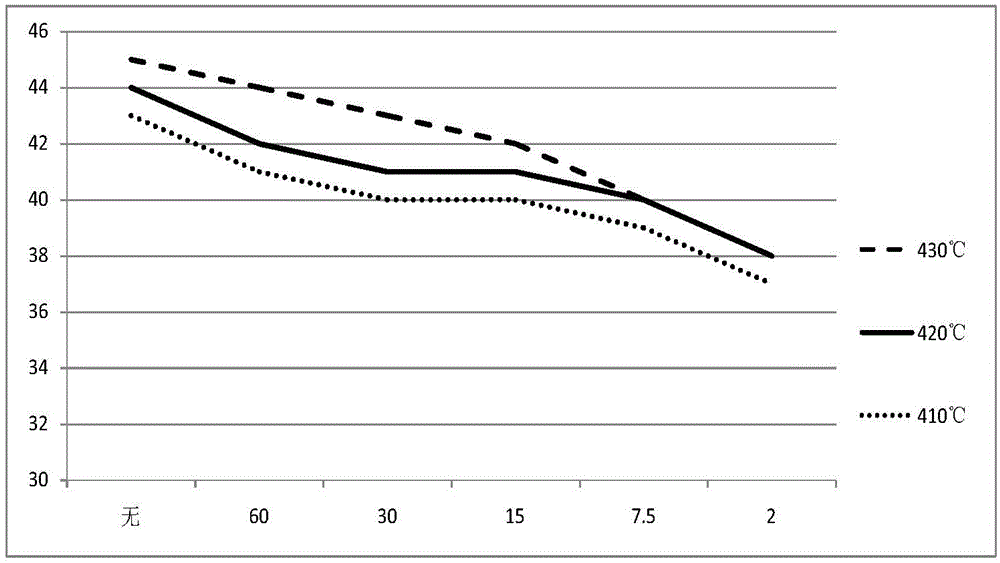

[0048] In Example 3, the influence of different annealing holding temperatures on the toughening performance, generally speaking, when the annealing temperature is lowered, the time for reorganization of the internal structure of the glass will be lengthened. Under the same holding time, when the temperature is higher, the glass interior reaches The degree of balance will increase. But there is a premise here, because the glass plate will be deformed by its own gravity during the annealing process, so a relatively low temperature should be selected during the annealing process or a short time should be kept at high temperature to prevent glass deformation. The heat preservation time of the sample is 6 hours, and the glass can achieve the purpose of improving the tempering performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com