Measuring-distance self-adaptive detecting sensor for line breaking of spinning machine

A technology of disconnection detection and sensing device, which is applied in the field of detection and sensing, can solve the problems of difficult to eliminate interference factors, narrow working space, easy to attach large, etc., and achieve convenient and fast installation and transformation, strong anti-interference ability, and small space occupation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail in combination with actual use cases and accompanying drawings of the description.

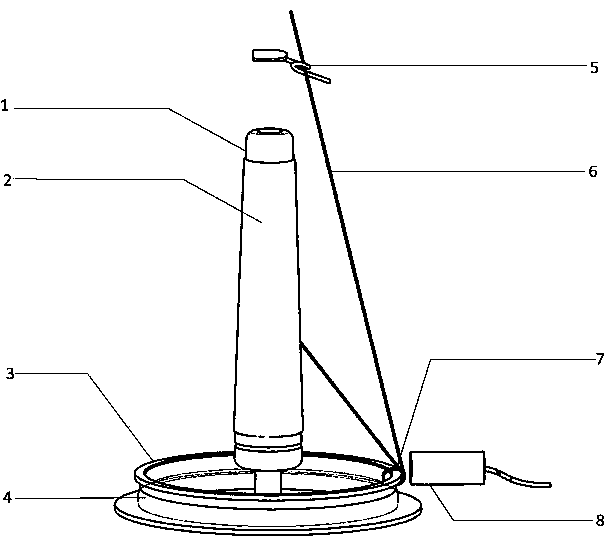

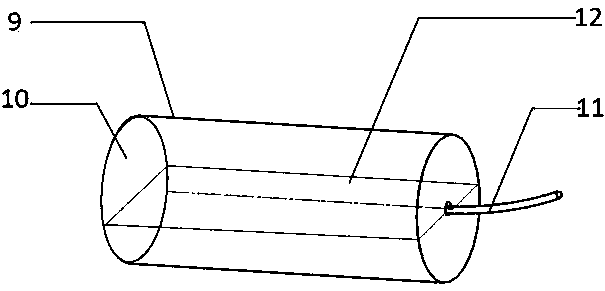

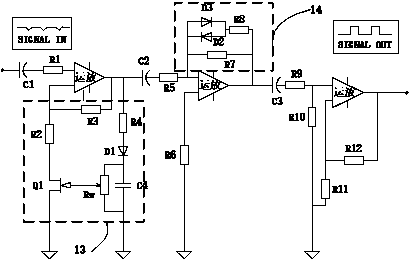

[0037] like figure 1 , figure 2 As shown, this example includes the steel ring 4 on the spinning working platform, the traveler 7 snapped on the ring track 3, the fine yarn 6 drawn out by the yarn guide hook 5 passes through the traveler 7 and is wound on the bobbin 1 . The wire breakage detection sensor 8 is located 5 mm outside the horizontal plane of the steel rim upper edge track 3 , and the wire breakage detection sensing device 8 includes an induction coil 10 , a casing 9 , a wire 11 and a signal processing circuit 12 .

[0038] During the working process, the fine yarn 6 first passes through the traveler 7 and then winds on the bobbin 1, and the bobbin 1 rotates at a high speed driven by the rotation of the spindle rod, and the fine yarn 6 is wound on the bobbin 1, and the twisting During the process, the spun yarn 6 drives the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com