Hydraulic formwork trolley for primary lining of loess tunnel

A technology for loess tunnels and formwork trolleys, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problems of long installation time, slow construction progress, large tunnel section, etc. Operation process, the effect of rapid mechanized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

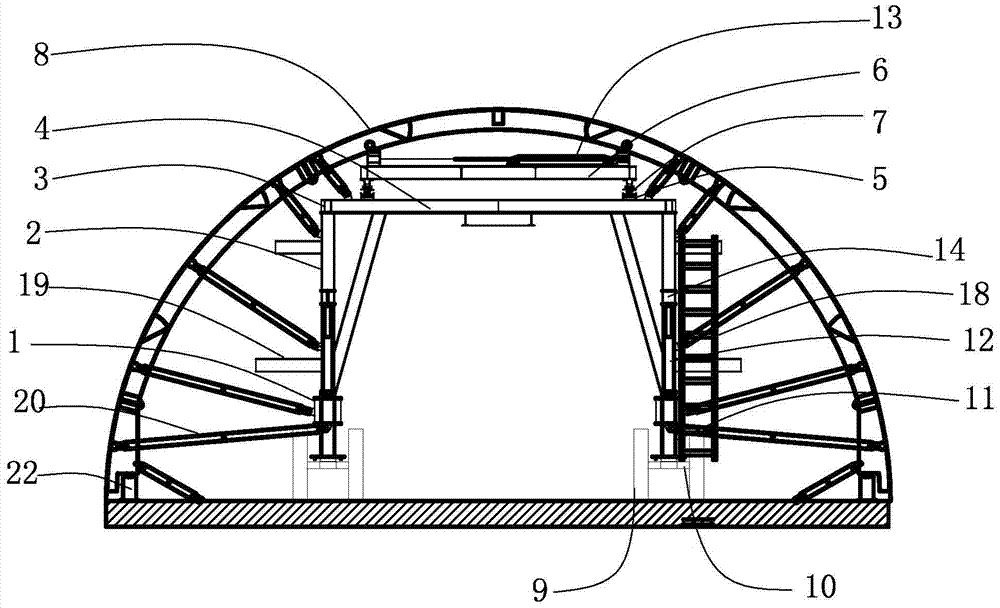

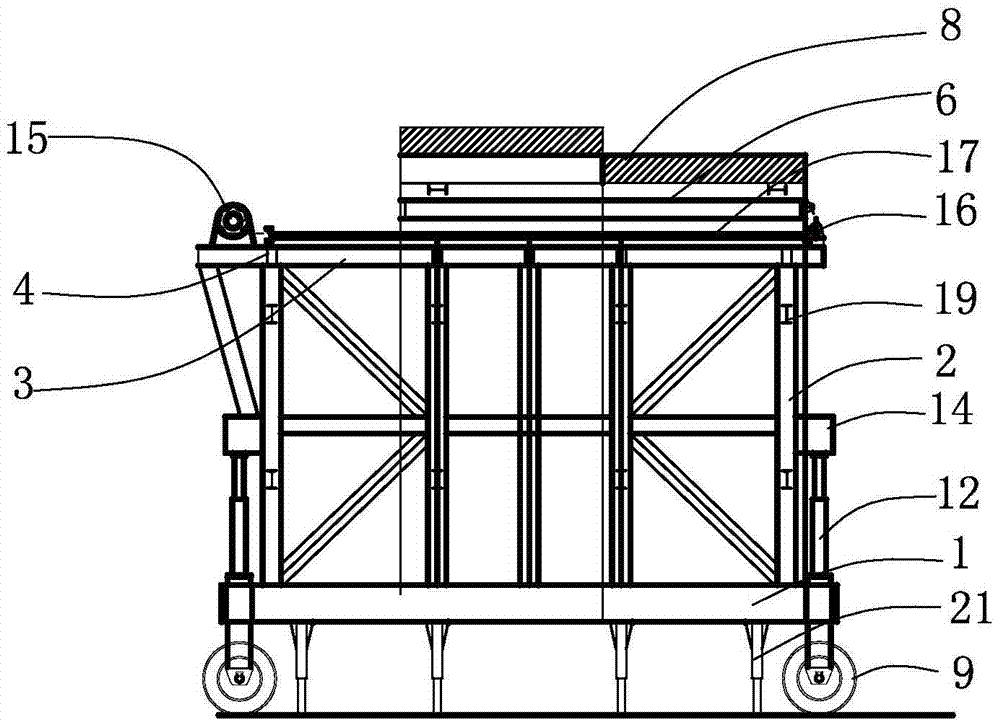

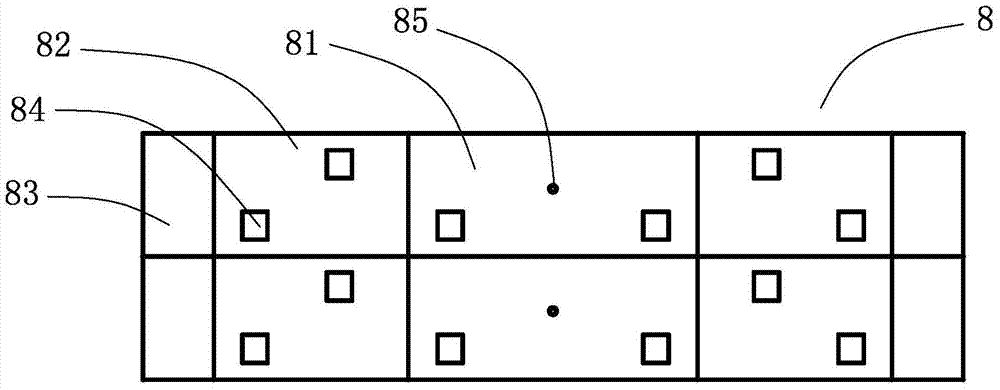

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a loess tunnel primary lining hydraulic formwork trolley of the present invention includes a portal frame and a formwork located on the upper part of the portal frame. The portal frame mainly includes two lower longitudinal beams 1 parallel to each other. A vertical brace 2 is arranged on the top, and the upper end of the vertical brace 2 is provided with an upper stringer 3 parallel to the lower stringer and a crossbeam 4 perpendicular to the upper stringer. The crossbeam 4 is provided with two guide rails 5 perpendicular to the crossbeam. Described guide rail 5 is provided with a rectangular template support frame 6, and the bottom of two sides parallel to guide rail of described template support frame 6 is provided with the slide rail 7 that slides along described guide rail; Described template 8 has two pieces, Two templates are arranged side by side on the upper part of the gantry, each template inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com