Multi-layer composite magnet and preparation method thereof

A multi-layer composite, magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem that the single-phase permanent magnet preparation process cannot be completely matched, cannot meet the use requirements in high temperature fields, and is prone to mutual diffusion and other problems, to achieve the effect of simple and feasible preparation method, low cost, and improved coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

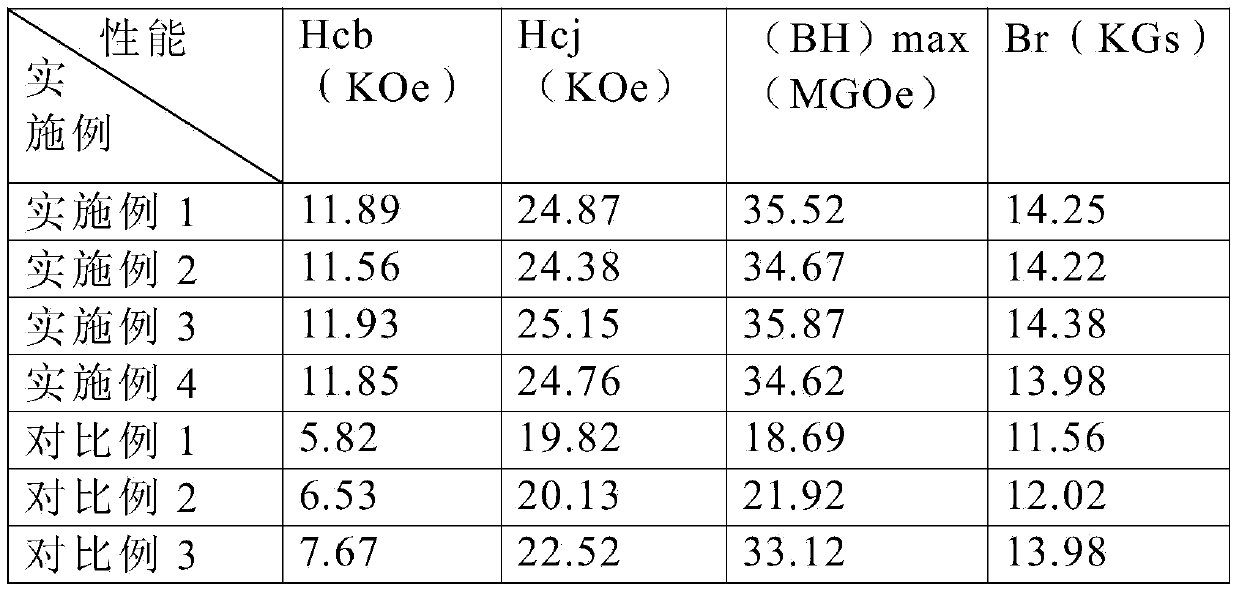

Embodiment 1

[0036] According to the composition and mass percentage of the NdFeB magnet as follows, the composition and mass percentage of the NdFeB magnet are: Nd: 27.00%, B: 2.20%, Si: 1.00%, Ga: 0.18%, Dy: 0.25% , V: 0.25%, the balance is Fe;

[0037] The NdFeB magnet blank was obtained by smelting, ingot casting, hydrogen crushing, jet milling, and compression molding of the ingredients. The NdFeB magnet blank was sintered at 1210°C for 0.6 hours, then dissolved in solid solution at 1170°C for 2 hours, and quickly air-cooled to room temperature to obtain For sintered compact, heat the sintered compact from room temperature to 815°C for 14 hours at a heating rate of 25°C / min, then cool slowly to 405°C at a cooling rate of 2°C / min, and hold for 3 hours to obtain a central layer NdFeB magnet ;

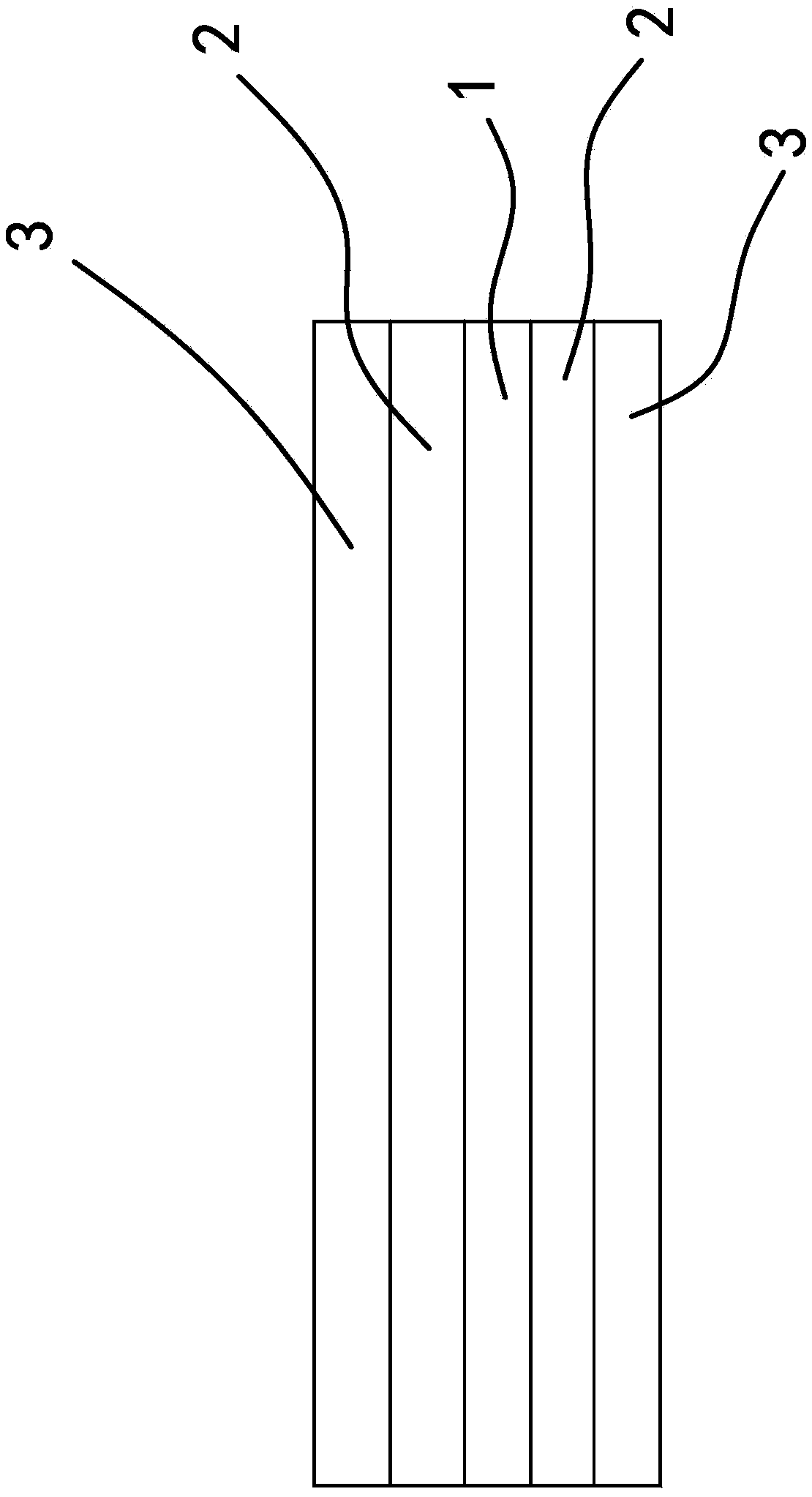

[0038] The middle layer of α-Fe and the outer layer of SmCo were sequentially deposited on the two sides of the central layer NdFeB magnet. 5 , the formed sandwich structure is the multilayer c...

Embodiment 2

[0040] According to the composition and mass percentage of the NdFeB magnet as follows, the composition and mass percentage of the NdFeB magnet are: Nd: 26.00%, B: 2.50%, Si: 0.80%, Ga: 0.20%, Dy: 0.10% , V: 0.30%, the balance is Fe;

[0041] The NdFeB magnet blank was obtained by smelting, ingot casting, hydrogen crushing, jet milling, and compression molding of the ingredients. The NdFeB magnet blank was sintered at 1220°C for 0.3 hours, then dissolved in solid solution at 1180°C for 2 hours, and quickly air-cooled to room temperature to obtain For sintered compact, heat the sintered compact from room temperature to 820°C for 12 hours at a heating rate of 30°C / min, then cool slowly to 420°C at a cooling rate of 3°C / min, and hold for 2 hours to obtain a central layer NdFeB magnet ;

[0042] The middle layer of α-Fe and the outer layer of SmCo were sequentially deposited on the two sides of the central layer NdFeB magnet. 5 , the formed sandwich structure is the multilayer c...

Embodiment 3

[0044] According to the composition and mass percentage of the NdFeB magnet as follows, the composition and mass percentage of the NdFeB magnet are: Nd: 28.00%, B: 1.80%, Si: 1.20%, Ga: 0.15%, Dy: 0.30% , V: 0.20%, the balance is Fe;

[0045] The NdFeB magnet blank was obtained by smelting, ingot casting, hydrogen crushing, jet milling, and compression molding of the ingredients. The NdFeB magnet blank was sintered at 1200°C for 0.4 hours, then dissolved in solid solution at 1160°C for 2.5 hours, and quickly air-cooled to room temperature to obtain For sintered compact, heat the sintered compact from room temperature to 810°C for 13 hours at a heating rate of 20°C / min, then cool slowly to 410°C at a cooling rate of 2°C / min, and hold for 2.5 hours to obtain a central layer NdFeB magnet ;

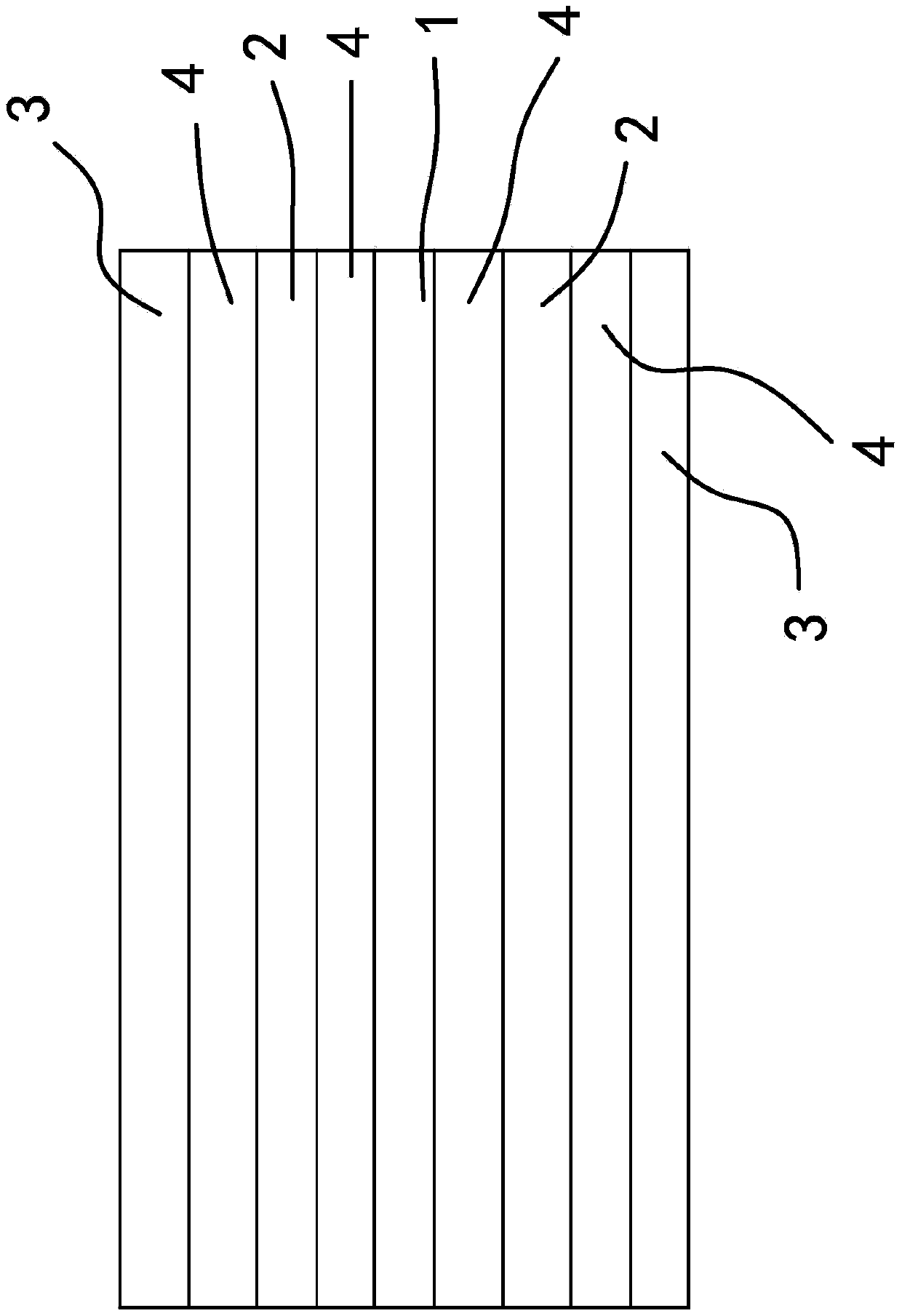

[0046] On the surface of both sides of the central NdFeB magnet, the Cu intercalation layer, the middle layer α-Fe, the Cu intercalation layer, and the outer layer of SmCo were sequentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com