Anti-jamming sorting machine

A technology for sorting machines and anti-jamming materials, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as material jamming and equipment performance reduction, and achieve the effect of reducing labor intensity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

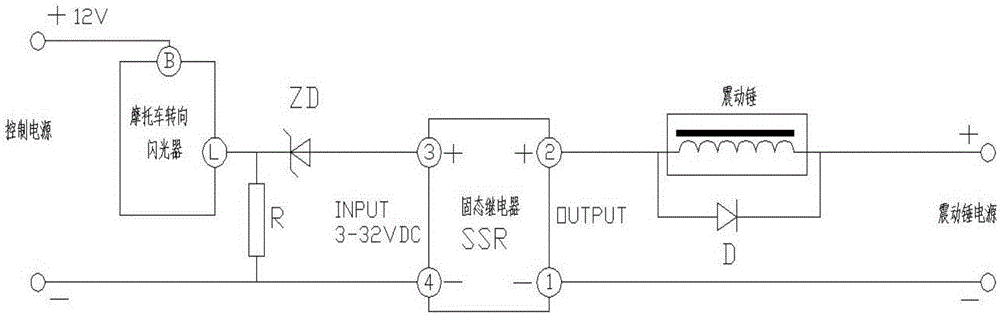

[0011] An anti-jamming sorting machine is mainly composed of a feeding mechanism, a separating mechanism and a vibrating mechanism. The above-mentioned feeding mechanism and separation mechanism continue to use the existing mechanism of the existing sorting machine, and the present invention does not improve it. The above-mentioned vibrating mechanism is an additional mechanism, which is the main improvement point of the present invention. Its function is to continuously and rhythmically beat the feeding track of the feeding mechanism to prevent material from being stuck.

[0012] In the present invention, the added vibrating mechanism includes a vibrating hammer and a vibrating hammer control circuit. Vibrating hammer selects the existing vibrating hammer of prior art for use.

[0013] In order to ensure the effective work of the vibrating hammer, the vibrating hammer needs to be vertically suspended directly above or directly below the feeding track, and the working surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com