Preparation method of solid cosmetic matrix and solid cosmetic matrix

A cosmetic matrix and solid-state technology, which is applied in the direction of cosmetic preparations, toiletry preparations, pharmaceutical formulations, etc., can solve the problems of uneven application, affecting the effect of cosmetics, scattering, etc., and achieve simple process, improved efficacy, and improved activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

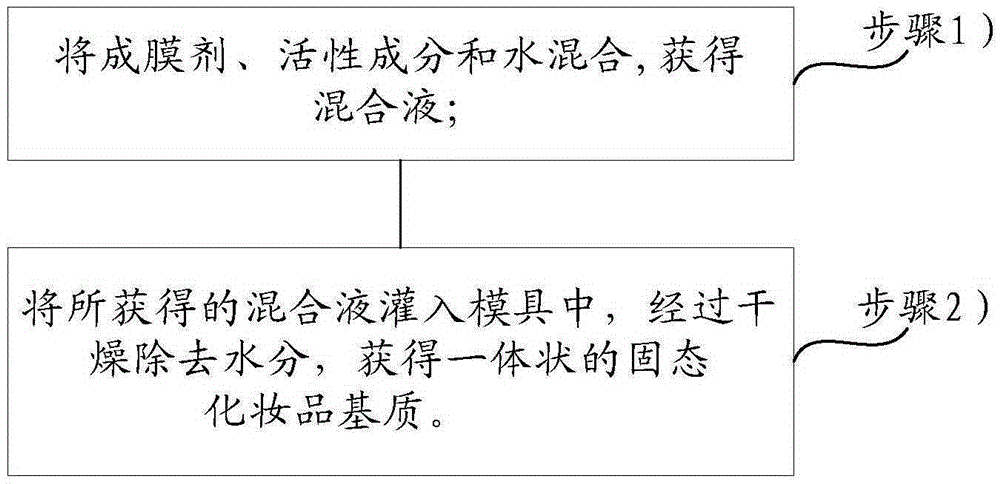

[0028] On the one hand, the embodiment of the present invention provides a kind of preparation method of solid cosmetic base, see figure 1 ,include:

[0029] Step 1) mixing the film-forming agent, the active ingredient and water to obtain a mixed solution;

[0030] Step 2) Pour the obtained mixed solution into a mold, and dry to remove moisture to obtain an integrated solid cosmetic base.

[0031] The embodiment of the present invention provides a method for preparing a solid cosmetic matrix. The method has a simple process, and obtains an integrated solid cosmetic base by drying and molding the mixed liquid of the film-forming agent, active ingredients and water, which can improve the toughness of the solid cosmetic base, and the obtained solid cosmetic base does not contain preservatives, It can improve the activity of the active ingredients in the solid cosmetic matrix, and it is not easy to loosen and fall off when used, and it can be dissolved into a cosmetic with certa...

Embodiment 1

[0058] The concrete preparation method of described embodiment 1 is as follows:

[0059] S1) Mixing the film-forming agent and the active ingredient with a mass ratio of 0.3:1 and water to obtain a mixed liquid; wherein, the viscosity of the mixed liquid is 150 mPa·s.

[0060] S2) Pour the obtained mixed solution into a mold, and freeze-dry to remove moisture to obtain a sheet-shaped solid cosmetic base.

[0061] Wherein, the freeze-drying is specifically:

[0062] Pre-freezing section: freeze the mold filled with the mixed solution at -10°C for 1.5 hours, so that the moisture in the mixed solution is frozen into ice;

[0063] Sublimation stage: under the vacuum degree of 8 Pa, the temperature is 10 ℃ for 5 hours, and the ice formed in the pre-freezing section is sublimated to remove the free water in the mixed solution;

[0064] Re-drying stage: under a vacuum degree of 5 Pa, the temperature is kept at 5° C. for 4 hours, and the bound moisture in the mixed liquid is removed...

Embodiment 2

[0067] The concrete preparation method of described embodiment 2 is as follows:

[0068] S1) Mixing the film-forming agent and the active ingredient with a mass ratio of 2:1 and water to obtain a mixed liquid; wherein, the viscosity of the mixed liquid is 250mPa·s.

[0069] S2) Pour the obtained mixed solution into a mold, and freeze-dry to remove moisture to obtain a sheet-shaped solid cosmetic base.

[0070] Wherein, the freeze-drying is specifically:

[0071] Pre-freezing section: freeze the mold filled with the mixed solution at -40°C for 2 hours, so that the moisture in the mixed solution is frozen into ice;

[0072] Sublimation stage: under the vacuum degree of 30Pa, the temperature is -10°C for 10h, and the ice formed in the pre-freezing section is sublimated to remove the free water in the mixed solution;

[0073] Re-drying stage: under the vacuum degree of 10 Pa, the temperature is kept at 10° C. for 10 h, and the bound water in the mixed liquid is removed.

[0074...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com