A kind of photocurable prepolymer adhesive and preparation method thereof

A prepolymer, light-curing technology, used in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of limiting the application of thiol/ene light-curing system and short storage period of finished products. Improved chemical stability, longer storage time, improved curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

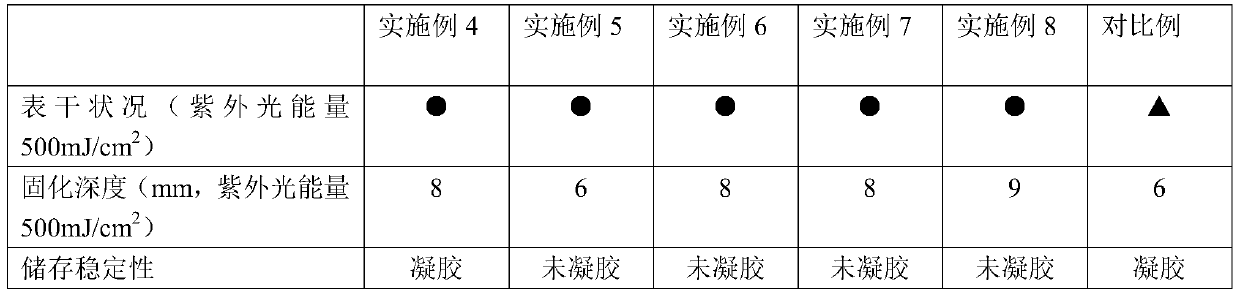

Examples

Embodiment 1

[0044] Synthesis of prepolymer PreP-1: 200 grams of polyester diol with a molecular weight (Mn) of 2000 and a hydroxyl value of about 56 was vacuum dehydrated at 120°C for 1 hour, and the dehydrated polyether diol, 44.46 Put 1,6-gram 1,6-diisocyanate together into the reactor, add 0.1 gram of dibutyltin dilaurate, react at 78°C for 4 hours, add 23.2 grams of 4-hydroxybutyl vinyl ether, 0.1 gram of hydroquinone to make As a polymerization inhibitor, continue to react at 78°C for 2 hours, cool to 45°C and discharge. It is called PreP-1.

Embodiment 2

[0046] Synthesis of prepolymer PreP-2: get 300 grams of polyether diol with a molecular weight (Mn) of 3000 and a hydroxyl value of about 37, and add C 12 -C 16 The proportion of alkyl alkoxy sulfate 10g will polyether glycol and C 12 -C 16 The alkyl alkoxy sulfate is fully mixed and reacted, the reaction temperature is 70°C, and the reaction time is 2 hours, the pretreatment process is completed. The modified polyether diol was vacuum dehydrated at 130°C for 2 hours, the dehydrated polyether diol and 45 grams of methylcyclohexyl diisocyanate were put into the reaction kettle together, and 0.2 grams of dilauric acid was added Dibutyltin, react at 80°C for 3 hours, add 26 grams of 4-hydroxybutyl vinyl ether, 0.1 gram of hydroquinone as a polymerization inhibitor, continue to react at 78°C for 2 hours, cool to 45°C and discharge Yes, call it PreP-2.

Embodiment 3

[0048] Synthesis of prepolymer PreP-3: 200 grams of polyether diol with a molecular weight (Mn) of 2000 and a hydroxyl value of about 56 was vacuum dehydrated at 120°C for 1 hour, and the dehydrated polyether diol, 44.46 Put 1 gram of isophorone diisocyanate into the reactor together, add 0.1 gram of dibutyltin dilaurate, react at 78°C for 3 hours, add 26 grams of hydroxyethyl methacrylate, and 0.1 gram of hydroquinone as a polymerization inhibitor agent, continue to react at 78°C for 2 hours, cool to 45°C and discharge, which is called PreP-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com