Thermal stress crack initiation method of surface annular groove root of bar blanking

A technology of annular groove and thermal stress, which is applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problems of increasing turning flat section process, reducing production efficiency, increasing production cost, etc., so as to shorten the blanking time and improve The effect of blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] A method for initiating thermal stress cracking at the root of an annular groove on the surface of a bar blanking, comprising the following steps:

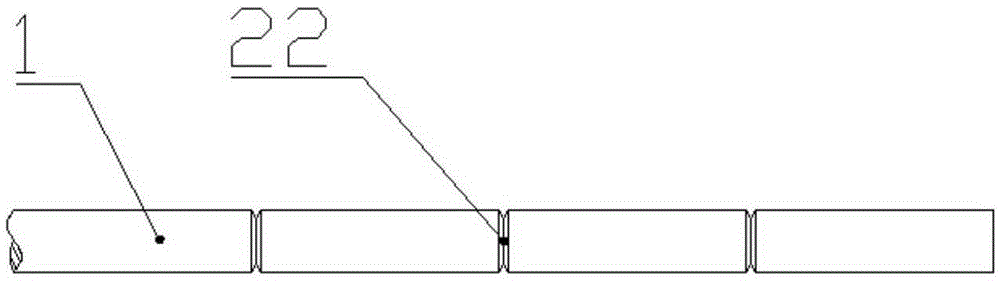

[0023] Step 1, according to the required blanking length, use a slotting machine to process equidistant annular grooves 22 on the surface of the metal bar 1, such as figure 1 shown;

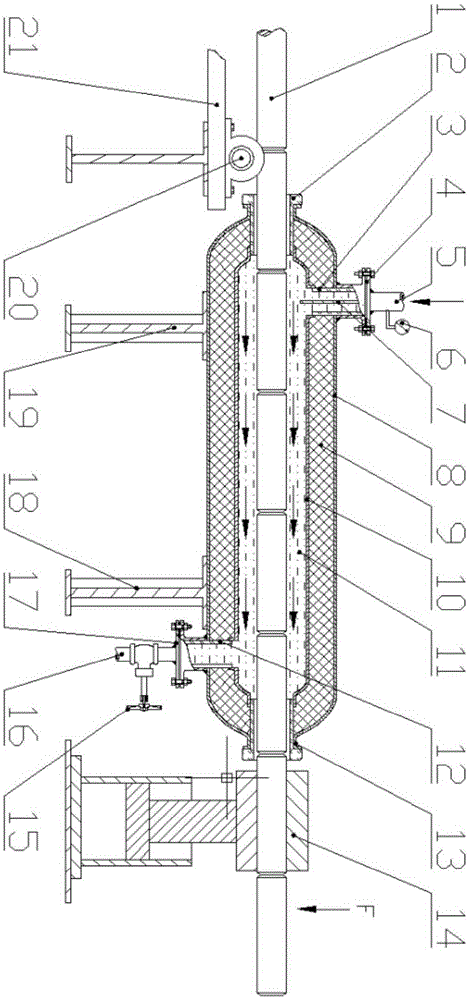

[0024] Step 2, refer to figure 2 , close the gate valve 15, quickly fill the cryogenic device with liquid nitrogen 11 through the liquid inlet pipe 5, and keep the temperature in the cryogenic device between -130°C and -196°C;

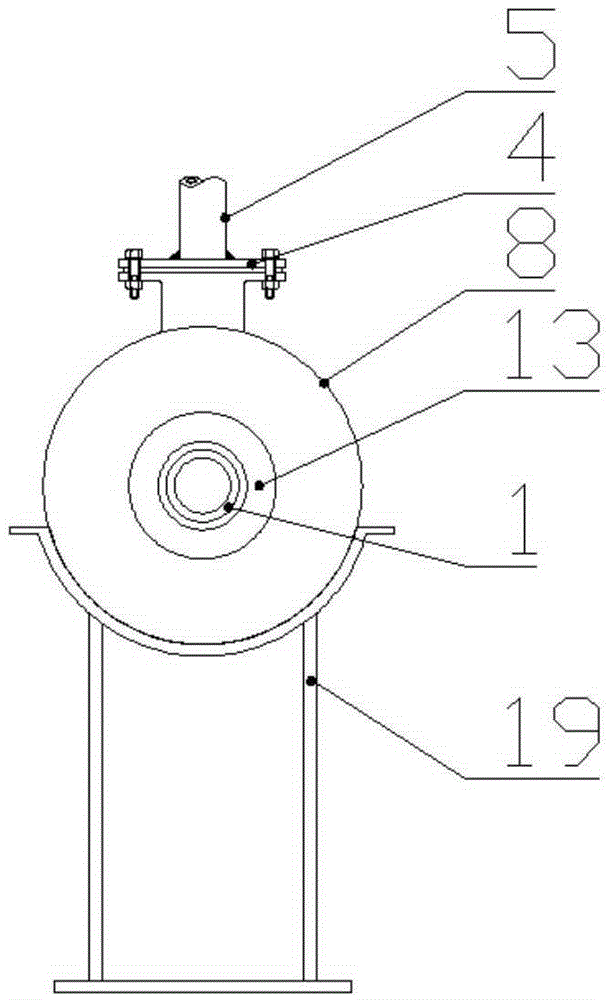

[0025] Step three, refer to figure 2 and image 3 Place the metal bar 1 on the feeding frame 21, and send it into the cryogenic device through the rollers 20 provided on the feeding frame 21 to carry out subsection rapid cryogenic cooling. At the moment of cooling, the surface of the metal bar 1 is rapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com