A kind of dissolvable alloy and its preparation method and application

An alloy and intermediate alloy technology, which is used in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve the problems of long production time for new wells, affecting the smoothness of the wellbore, labor and time-consuming, etc., and achieve reasonable component design. , convenient operation, simple and reasonable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

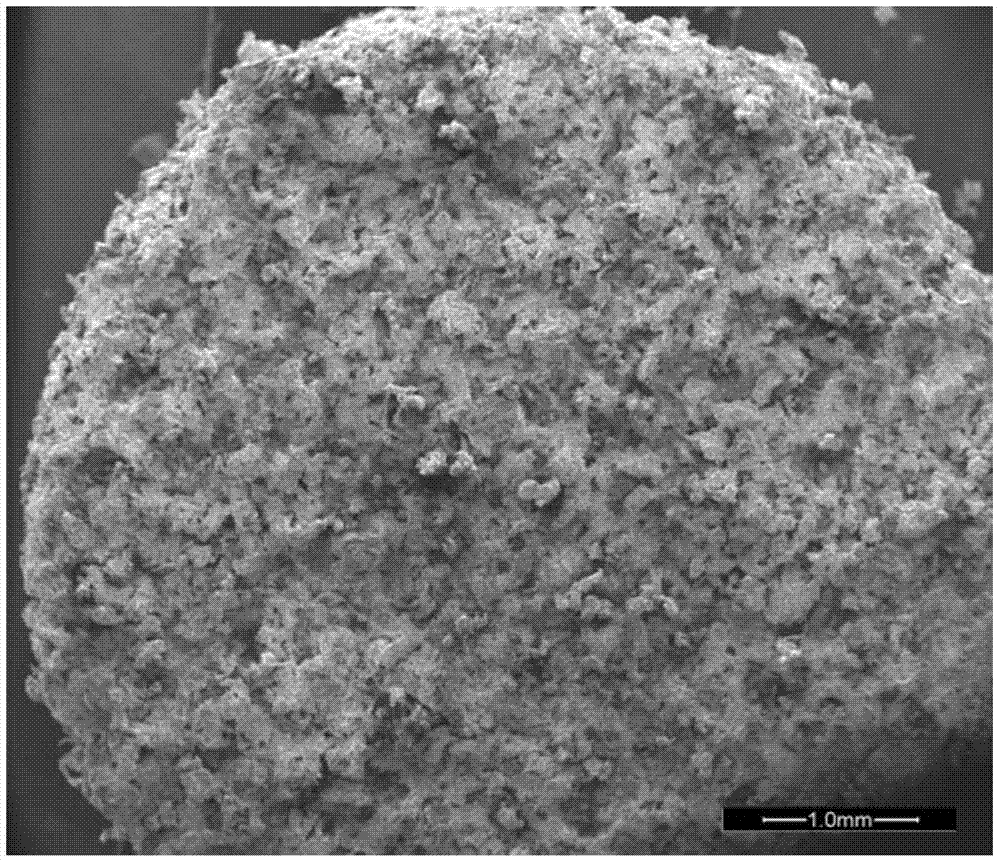

Image

Examples

Embodiment 1

[0032] This example provides a dissolvable alloy.

[0033] In terms of mass percentage, the soluble alloy in this embodiment contains: aluminum 3.4-3.5wt%, silicon 2.0-2.2wt%, copper 1.5-1.6wt%, tin 2.0-2.1wt%, zinc 1.4-1.5wt% and The balance of magnesium.

[0034] Preparations before preparing dissolvable alloys:

[0035] Prepare materials according to the designed composition ratio, wherein the amount of Si is converted to the amount of Al-50wt% Si master alloy; the amount of aluminum includes the amount in the above master alloy and the amount of metal aluminum; metal magnesium, aluminum, copper, The purity of tin and zinc are both 99.9%; the Al-50wt% Si master alloy is pre-ground.

[0036] The process of preparing a dissolvable alloy involves the following steps:

[0037] 1. Use electromagnetic induction furnace for melting, put the metal magnesium, aluminum, copper, tin and zinc prepared according to the ratio into the melting furnace crucible, under electromagnetic st...

Embodiment 2

[0043] This example provides a dissolvable alloy.

[0044] In terms of mass percentage, the soluble alloy in this embodiment contains: aluminum 3.9-4.0wt%, silicon 2.2-2.3wt%, copper 2.3-2.4wt%, tin 2.7-2.8wt%, zinc 0.7-0.8wt% and The balance of magnesium.

[0045] Preparations before preparing dissolvable alloys:

[0046] Prepare materials according to the designed composition ratio, wherein the amount of Si is converted to the amount of Al-50wt% Si master alloy; the amount of aluminum includes the amount in the above master alloy and the amount of metal aluminum; metal magnesium, aluminum, copper, The purity of tin and zinc are both 99.9%; the Al-50wt% Si master alloy is pre-ground.

[0047] The process of preparing a dissolvable alloy involves the following steps:

[0048] 1. Use electromagnetic induction furnace for smelting, put the metal magnesium, aluminum, copper, tin and zinc prepared according to the ratio into the crucible of the melting furnace, under electromag...

Embodiment 3

[0054] This example provides a dissolvable alloy.

[0055] In terms of mass percentage, the soluble alloy in this embodiment contains: aluminum 4.1-4.2wt%, silicon 2.9-3.0wt%, copper 3.0-3.1wt%, tin 3.1-3.2wt%, zinc 1.9-2.0wt% and The balance of magnesium.

[0056] Preparations before preparing dissolvable alloys:

[0057] Prepare materials according to the designed composition ratio, wherein the amount of Si is converted to the amount of Al-50wt% Si master alloy; the amount of aluminum includes the amount in the above master alloy and the amount of metal aluminum; metal magnesium, aluminum, copper, The purity of tin and zinc are both 99.9%; the Al-50wt% Si master alloy is pre-ground.

[0058] The process of preparing a dissolvable alloy involves the following steps:

[0059] 1. Use electromagnetic induction furnace for smelting, put the metal magnesium, aluminum, copper, tin and zinc prepared according to the ratio into the crucible of the melting furnace, under electromagne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com