Green energy environmental control fiber, manufacturing method of the same and texture made from the fiber

A technology for controlling fabrics and fibers, which is applied in the field of green energy environmental control fibers, its manufacturing method and fabrics made of the fibers, can solve the problems of high cost, inability to prevent pests and diseases, expensive equipment, etc., and achieve effective absorption and increase transfer Harmful light waves, promote the effect of sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

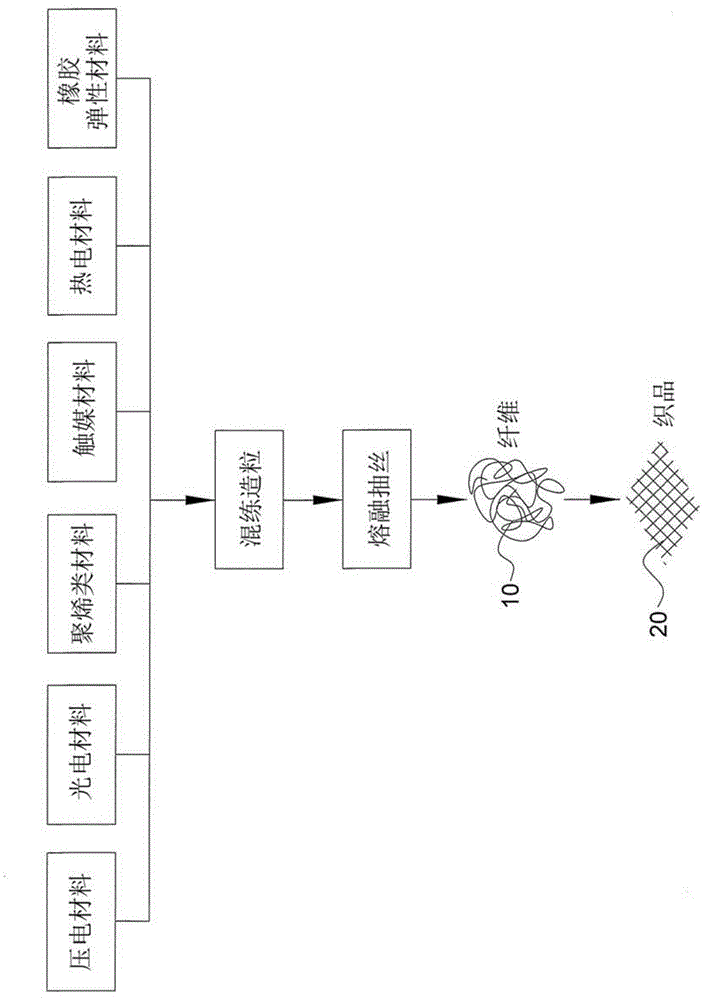

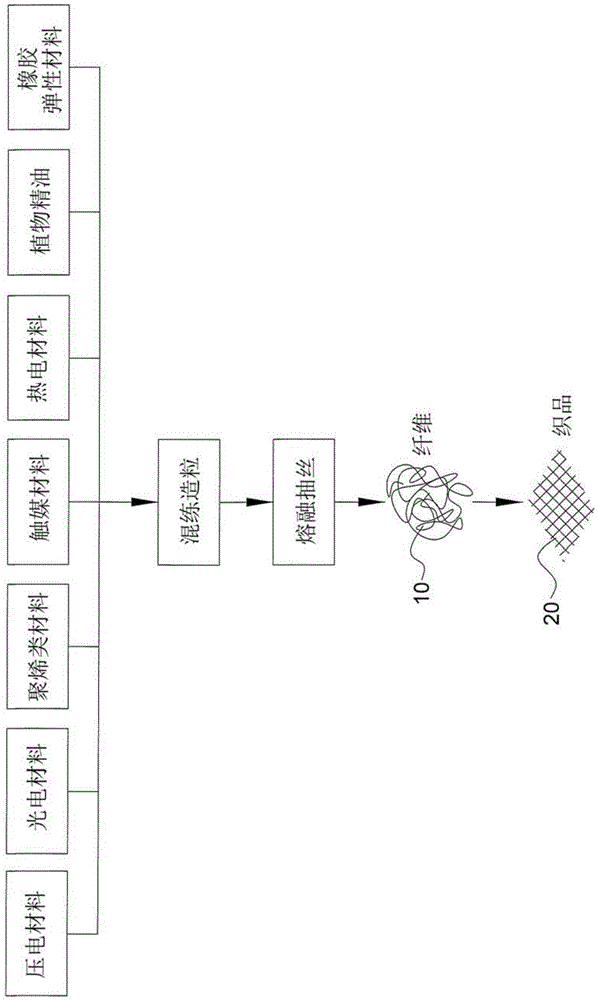

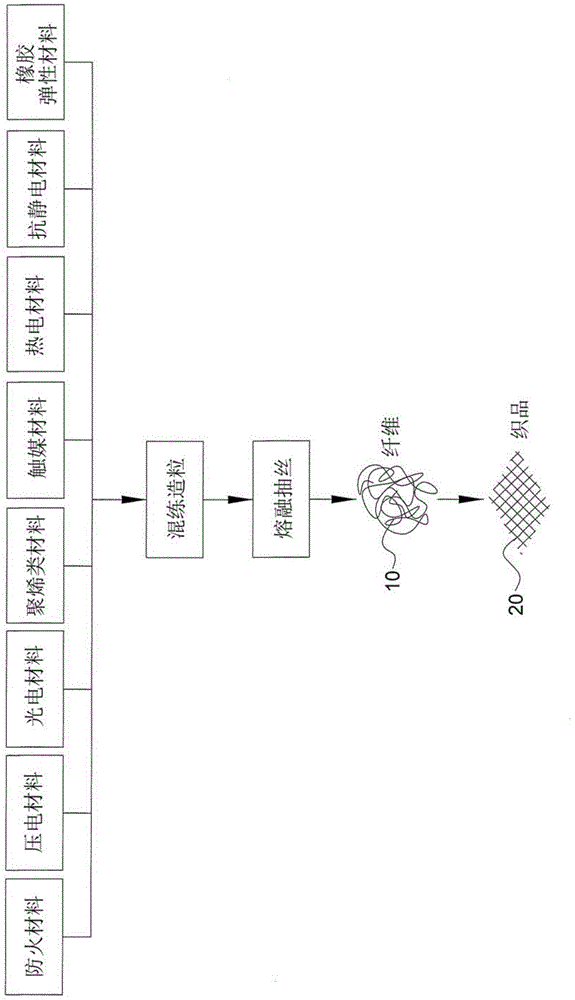

Method used

Image

Examples

Embodiment 1

[0043] For the tensile strength and tear strength test results of Example 1, please refer to Table 1: as the content of photoelectric materials, piezoelectric materials, thermoelectric materials, catalyst materials and EPDM increases, the tensile strength will gradually decrease, but Still retain the required strength, so the optoelectronic material, piezoelectric material, pyroelectric material, catalyst material and EPDM added in the present invention account for 20-30% of the overall weight is better (the example in Table 1 adds a total of 20% for illustration). Light storage effect (Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ Blue-green light (488nm) has 956 minutes of benefit. The wavelength of 400-520nm increases the development of plant roots and stems, has the greatest absorption of chlorophyll and carotenoids, and has the greatest impact on photosynthesis. 610~720nm wavelength promotes photosynthesis and plant growth rate (CaAl 12 o 19 :Mn 4+ red light 656nm).

[0044] Ta...

Embodiment 2

[0077] The physical property of the fabric of embodiment two, please refer to shown in table 11:

[0078] Table 11

[0079] Mesh

Fiber Denier Number (d)

50*50

200

1m 2

98g

[0080] The dust mite avoidance test result avoidance rate (90.3%) of embodiment two, please refer to shown in table 12:

[0081] Table 12

[0082]

[0083] Please refer to Table 13 for the detection results of essential oil components in Example 2-gas chromatography mass spectrometry (GC / MS). Set up the tested product in a 1 cubic meter airtight test box, and turn on the tested product for 1 hour test. The essential oil components of this product can be obtained as shown in Table 13. Test method: connected to a gas chromatography mass spectrometer (GC / MS) for detection.

[0084] Table 13

[0085] No.

CAS NO.

Test results

unit

1

α-terpipnen

000099-86-5

...

Embodiment 3

[0090] The toxic gas content test result of embodiment three: meet the regulations. Please refer to Table 15 for the toxic gas content: the ToxicGas value in this report refers to the toxic gas content produced in the combustion test for 4 minutes. ABD0031(2005) ISSUE: Requirements of F: HF2 2 <100, CO<1000.

[0091] Table 15

[0092]

[0093] The horizontal burning test result of embodiment three: meet the regulations. See Table 16 for details. FAR25.853(b) (Amdt. 25-116, 2004) & Appendix FParI(a)(1)(ii). Flame Time (FlameTime): ≦15Sec; Drip Flame Time (DripFlameTime): ≦5Sec; Burn Length (BurnLength): ≦8in (203.2mm).

[0094] Table 16

[0095]

[0096] Vertical combustion test result test result of embodiment three: meet the regulations. Please refer to Table 17. FAR25.853 Appendix AppendixFAmdt.25-111. te(10)=te(11.5)-te(1.5).

[0097] Table 17

[0098]

[0099] The smoke concentration test result of embodiment three: meet the regulations. Please refer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Danny number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com