Advanced roller flow control valve and application

A flow regulation, advanced technology, applied in the direction of flow control, control/regulation system, non-electric variable control, etc., can solve the problems of unable to achieve quantitative regulation, flow change, out of control, etc., achieve simple structure, improve reliability, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

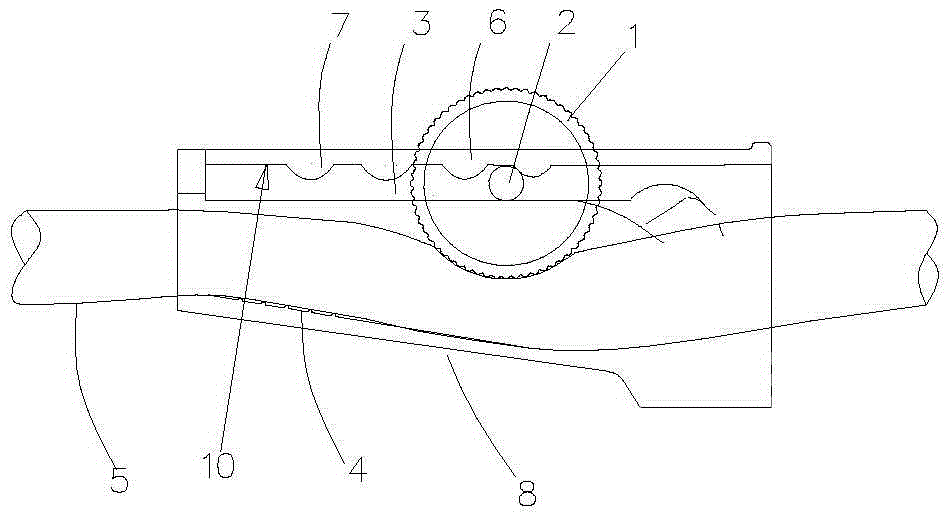

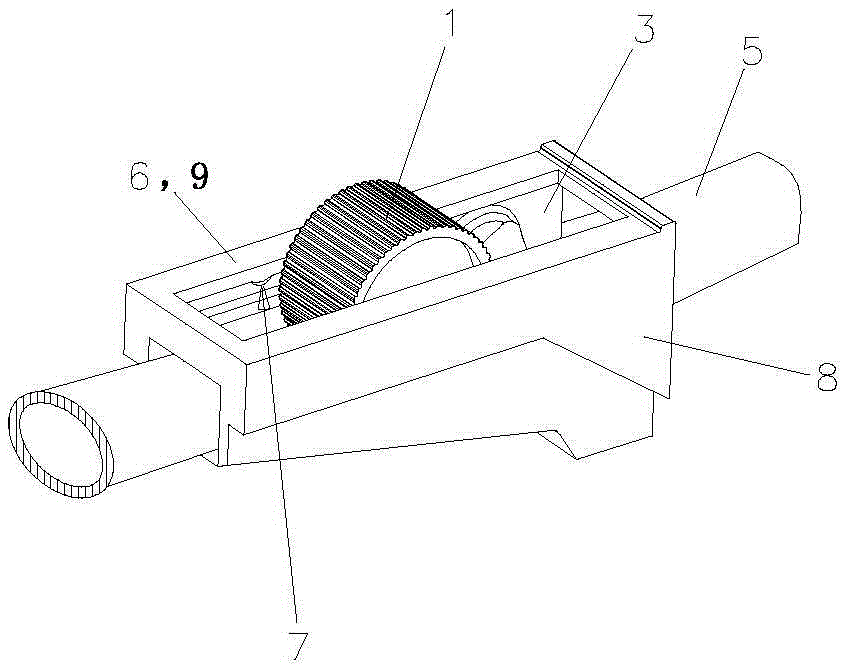

[0029] Such as Figure 1-3 shown.

[0030] An advanced roller flow adjustment switch, which includes a roller 1 and a roller groove 3, which constrains the conduit 5 through which the fluid passes to perform advanced flow control and each stage of limit locking; the roller groove 3 contains advanced The step limit structure 7 is used to adjust the roller to enter each step and fix it in its position, so as to realize the functions of flow regulation and fixed lock; the advanced limit mechanism 7 contains one or more limit structures of different shapes , to achieve different flow control functions and fixed at each stage to keep the flow stable. See attached figure 1 The roller 1 of the advanced roller flow regulating switch of the present invention is fixedly installed on the roller shaft 2, at least one end of the roller shaft 2 protrudes from the end surface of the roller to prevent the roller 1 from breaking away from its roller groove 3, and the roller shaft protrudes f...

Embodiment 2

[0032] Such as Figure 4-6 shown.

[0033] As a case of a typical application of the present invention, such as Figure 4 A flushing catheter is shown, which includes a hand-held part 11, a flushing catheter 12 and a negative pressure suction catheter 13. The hand-held part 11 is equipped with a first step roller flow adjustment device for controlling the flow of the flushing catheter 12. The switch 14 and the second progressive roller flow regulating switch 15 for controlling the suction force of the negative pressure suction catheter 13 . The roller groove 3 for installing the roller 1 in the first progressive roller flow regulating switch 14 and the second progressive roller flow regulating switch 15 is directly formed on the handle 11 body. In specific implementation, the switch of the first embodiment can also be directly installed on the handle 11 of the embodiment.

Embodiment 3

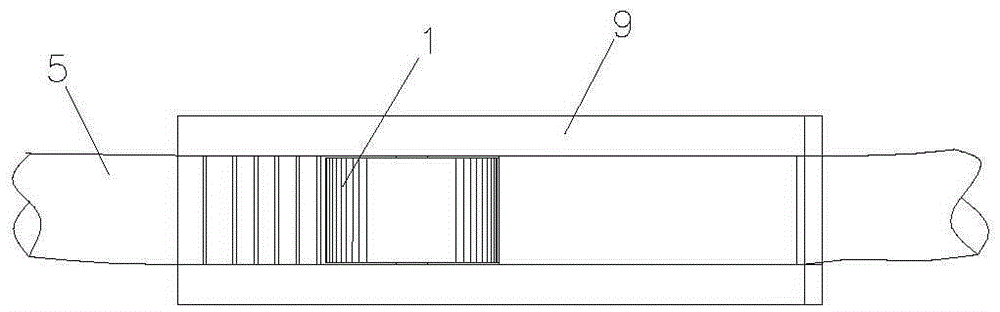

[0035] Such as image 3 shown.

[0036] An advanced roller flow regulating switch for infusion, which includes an installation housing 8, an infusion tube 5 passes through the installation housing 8, a roller 1 is installed on a roller shaft, and both ends of the roller shaft protrude from the end surface of the roller 1, The roller shaft 2 is constrained in the roller groove 3 by the elongated constraining structure 6 on the upper part of the installation housing, and a plurality of advanced limit structures 7 are arranged on the lower surface of the constraining structure 6 . When in use, the roller shaft 2 is driven by the rolling roller 1 to move along the constraint structure 6. During the movement, it is constrained by the inclined surface structure 4, the conduit 5 is squeezed, and the channel becomes smaller. When it moves to the desired position, the roller 1 is released. The roller shaft will automatically stop between the two adjacent advanced limit structures 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com