Optical axis consistency calibration method for multi-optical axis ground star observation system

An observation system, star technology, applied in the testing of optical instruments, measuring devices, testing of machine/structural components, etc., can solve problems such as difficult optical axis detection, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

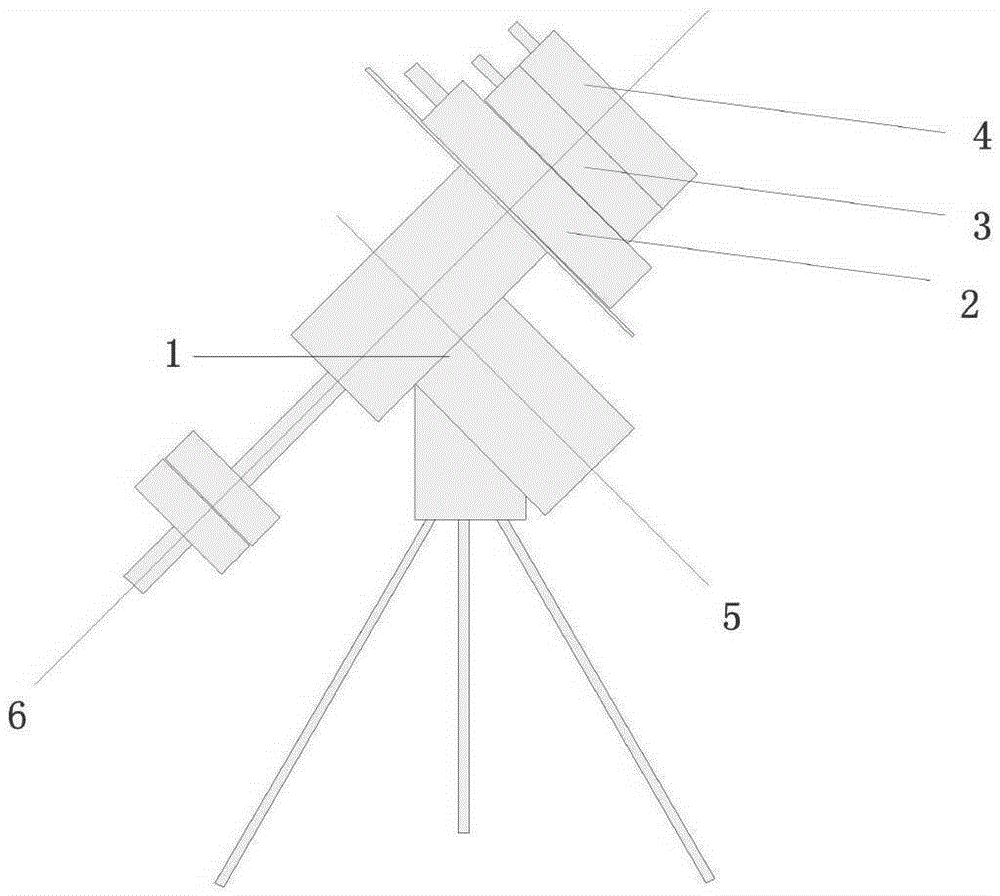

[0013] Such as figure 1 As shown, the ground star observation system is mainly composed of an equatorial mount 1 and a telescope 3. The equatorial mount is mainly composed of a right ascension axis 5 (polar axis) and a declination axis 6. The telescope 3 is used to calibrate the polar axis of the equatorial mount 1. In this example It is used to calibrate the optical axis parallelism of the telescope 3, the imaging spectrometer 2 and the imager 4, wherein the telescope 3, the imaging spectrometer 2 and the imager 4 are mechanically fixed to each other in advance and roughly adjusted to be parallel.

[0014] The multi-optical axis ground star observation system optical axis consistency check method includes the following three steps;

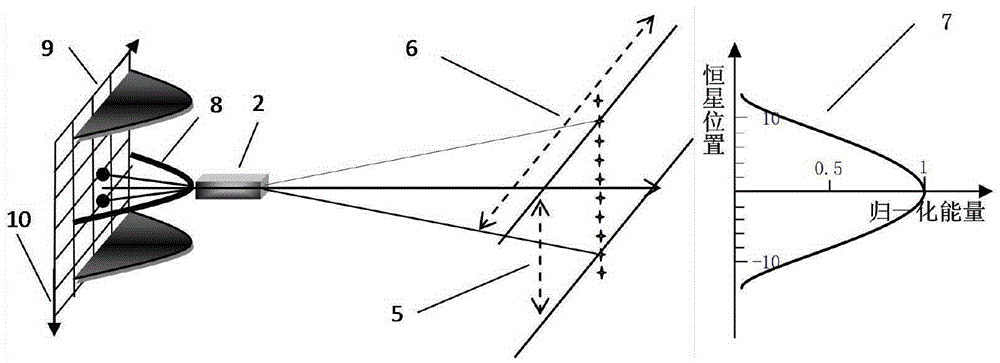

[0015] 1. Determine the position of the target star in the field of view of spectral dimension 10 in the imaging spectrometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com