Method for determining hydrophilic-hydrophobic properties of bisphenol compounds

A technology for compounds and bisphenols, which is applied in the field of determining the hydrophilicity and hydrophobicity of bisphenols, which can solve the problems of physical injury, time-consuming, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

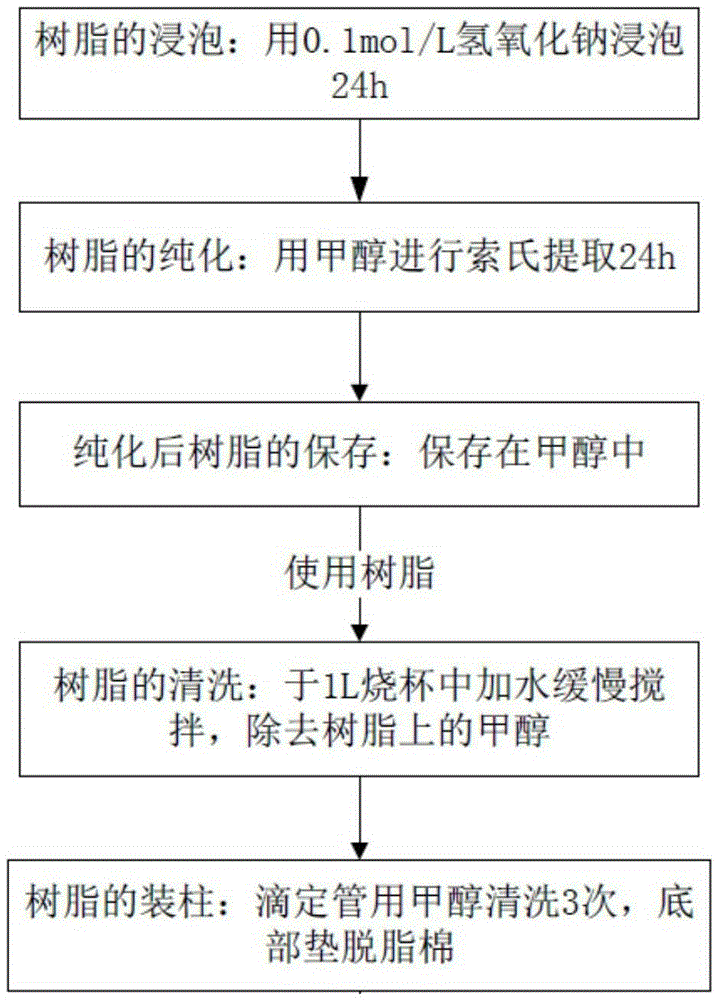

[0025] Specific implementation mode one: combine figure 1 A method for measuring the hydrophilicity and hydrophobicity of bisphenol compounds in this embodiment is specifically prepared according to the following steps:

[0026] Step 1. Before XAD8 resin and XAD4 resin are loaded into the resin column, the XAD8 resin or XAD4 resin needs to be purified; XAD8 resin and XAD4 resin are respectively soaked in 0.1-0.2mol / L sodium hydroxide for 1 day, and the soaked The XAD8 resin and XAD4 resin were purified by Soxhlet extractor for 20-26 hours, and the purified XAD8 resin and XAD4 resin were stored in pure methanol respectively;

[0027] Step 2. Before loading the resin column, clean the XAD8, XAD4 resin and the resin column; respectively put the XAD8 resin and XAD4 resin stored in pure methanol in step 1 into a 1L beaker, add 600-800mL of ultrapure water, and stir for 2 After ~4min of static settling, discard the supernatant; wash repeatedly for 7-10 times; obtain the cleaned XAD...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of sodium hydroxide in step 1 is 0.125-0.175 mol / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0045] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the soaked XAD8 resin and XAD4 resin in step 1 are purified by Soxhlet extractor for 21-25 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com