Device for cleaning to-be-tinned copper belt surface with soldering flux

A technology of tin-coated copper tape and flux, used in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as frame corrosion, poor tin coating, and unqualified, and achieve a stable use process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

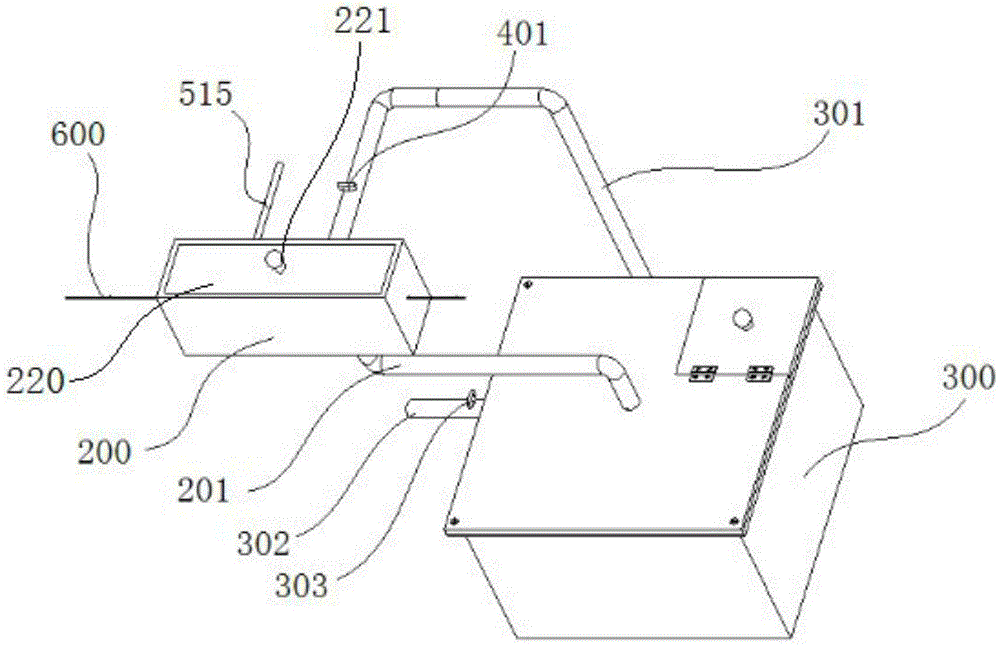

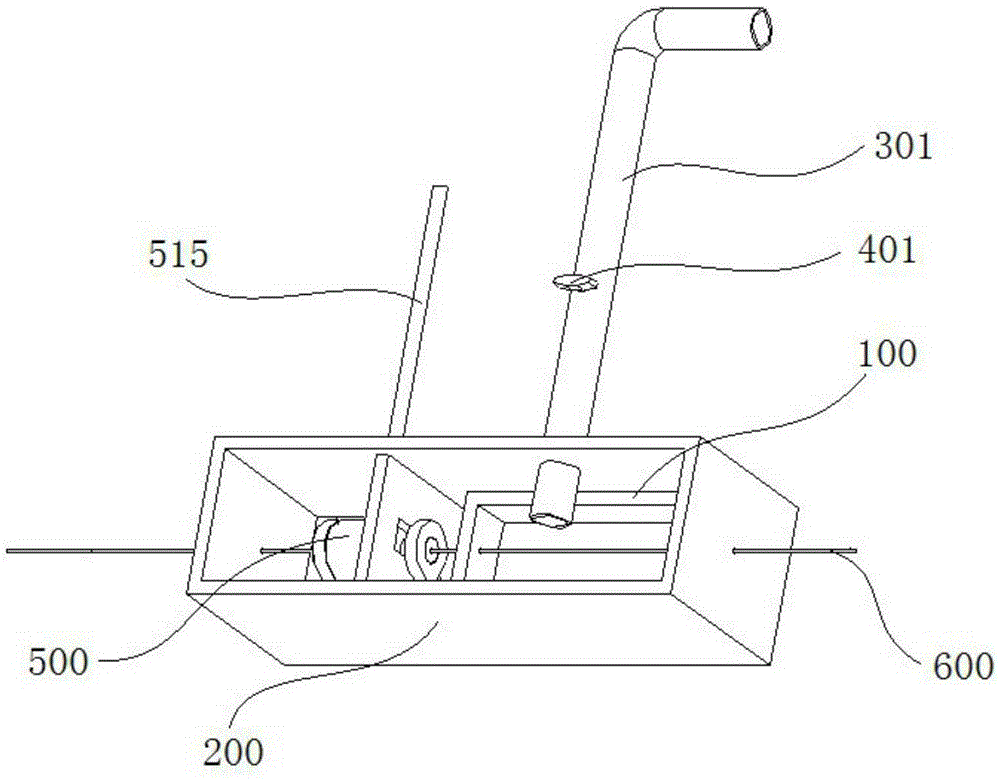

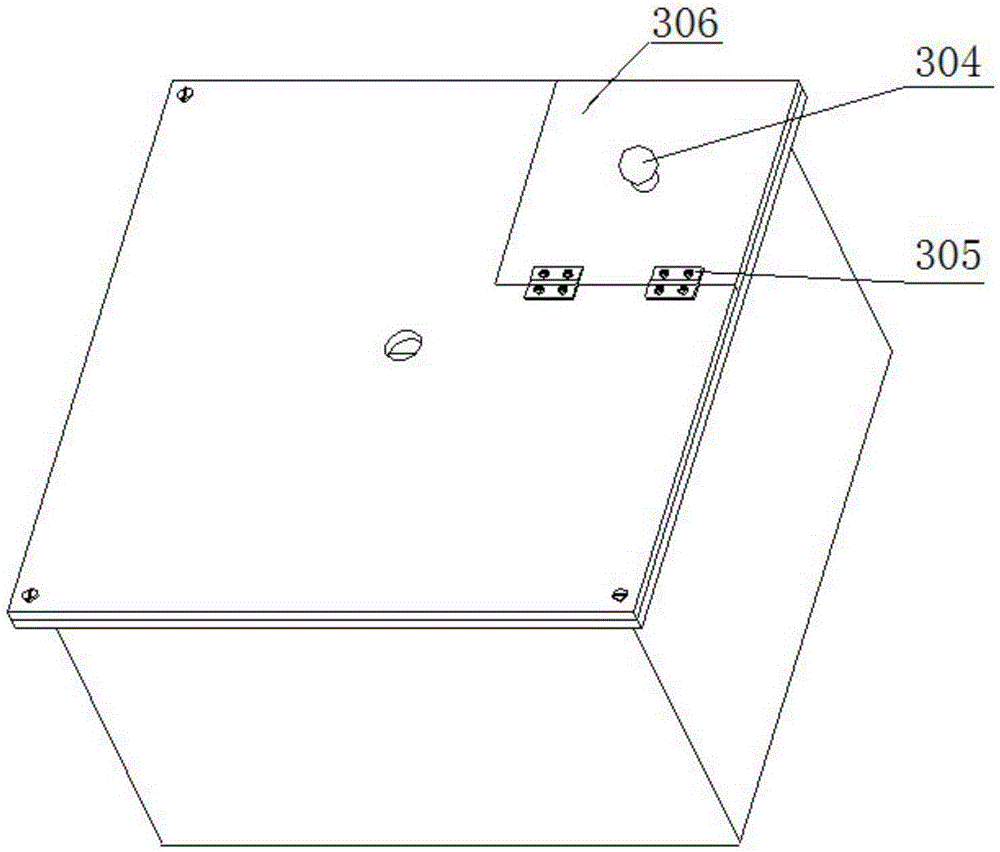

[0025] Such as Figure 1-9 As shown, the device of the present invention that uses flux to clean the surface of the copper strip to be tinned includes a copper strip soaking tank 100, a flux overflow tank 200, a flux storage recovery tank 300, a water pump 400, a liquid remover 500 and a compression Air source (not shown in the figure); Copper strip soaking tank 100 and liquid remover 500 are placed in the flux overflow tank 200, and the relative positions of copper strip soaking tank 100 and flux overflow tank 200 are all set There are two small holes 101, 102, 201 and 202 for passing through the copper strip to be tinned, and the four small holes are on the same horizontal line; the upper part of the flux overflow tank is provided with a cover 220, and the cover is provided with a handle 221; The liquid container 500 is connected with the compressed air source, and its air outlet is aligned with the copper strip 600 to be tinned; the flux overflow tank 200 is arranged at a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com