Hybrid excitation fault-tolerant motor system based on brushless harmonic excitation

A hybrid excitation and harmonic excitation technology, applied in synchronous motors with stationary armatures and rotating magnets, magnetic circuits, synchronous machines, etc., can solve problems such as poor fault-tolerant running performance, permanent magnet demagnetization and difficulty in excitation adjustment, etc. Achieve high power density and efficiency, improved reliability and fault-tolerant operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

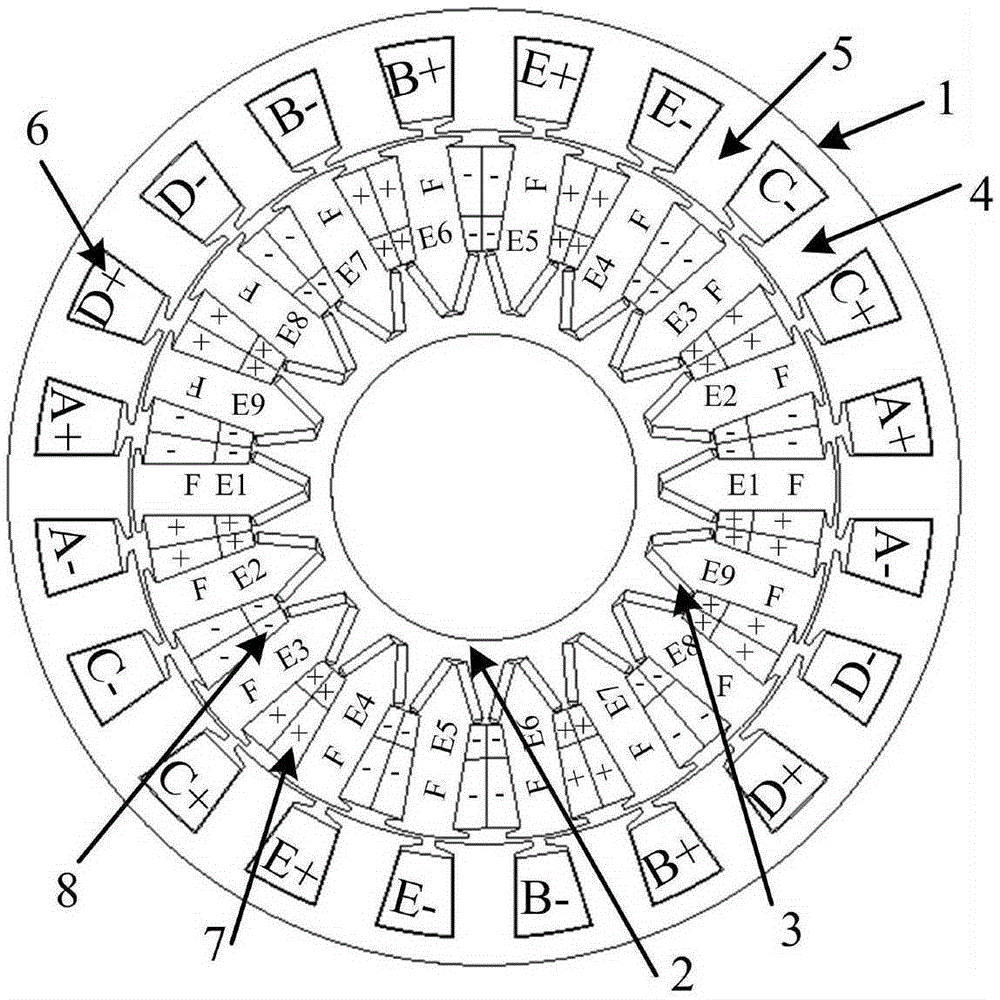

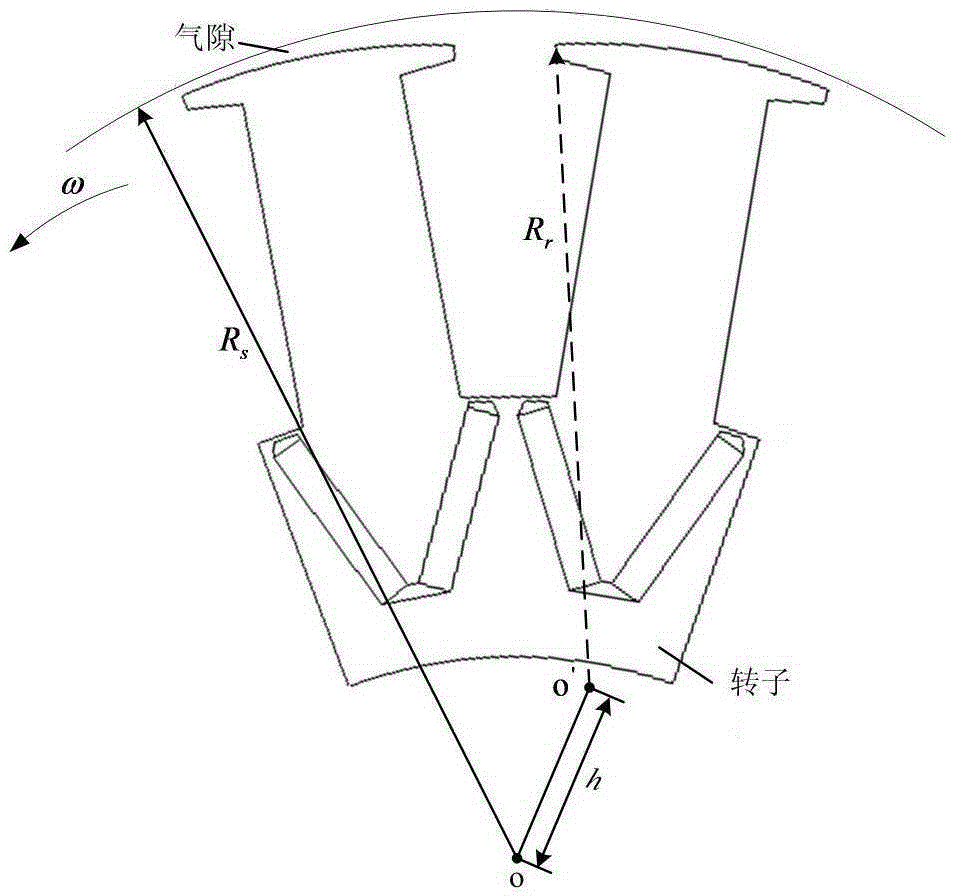

[0020] like figure 1 Shown is a five-phase hybrid excitation fault-tolerant motor based on brushless harmonic excitation, including stator 1, rotor 2, permanent magnet 3, armature teeth 4, fault-tolerant teeth 5, armature winding 6, field winding 7 and harmonic Winding 8. The armature teeth 4 and the fault-tolerant teeth 5 are evenly distributed along the inner circle of the stator 1, the total number of teeth is a multiple of 2m (m is the phase number of the motor), and the tooth width of the armature teeth 4 and the tooth width of the fault-tolerant teeth 5 are different. equal. The armature teeth 4 are wound with armature windings 6, which are single-layer concentrated windings. Two adjacent single-layer concentrated windings are isolated by fault-tolerant teeth 5, which provide magnetic flux circuits and at the same time achieve magnetic isolation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com