X-ray source, high-voltage generator, electron beam gun, rotary target assembly, rotary target, and rotary vacuum seal

A high-voltage electrode and electron beam generator technology, applied in the field of x-ray sources, can solve the problem of not producing x-ray sources and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

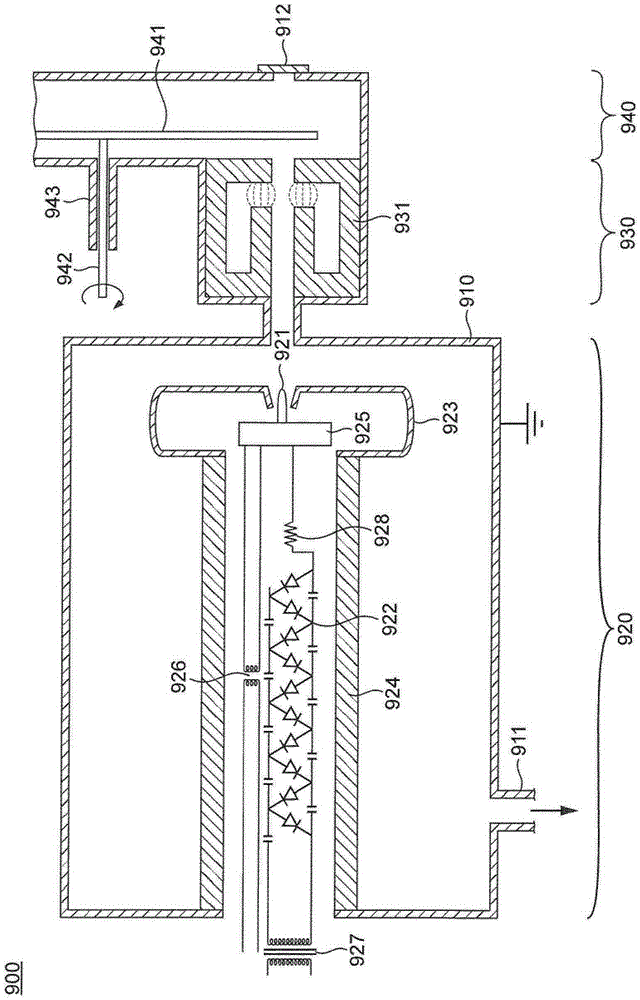

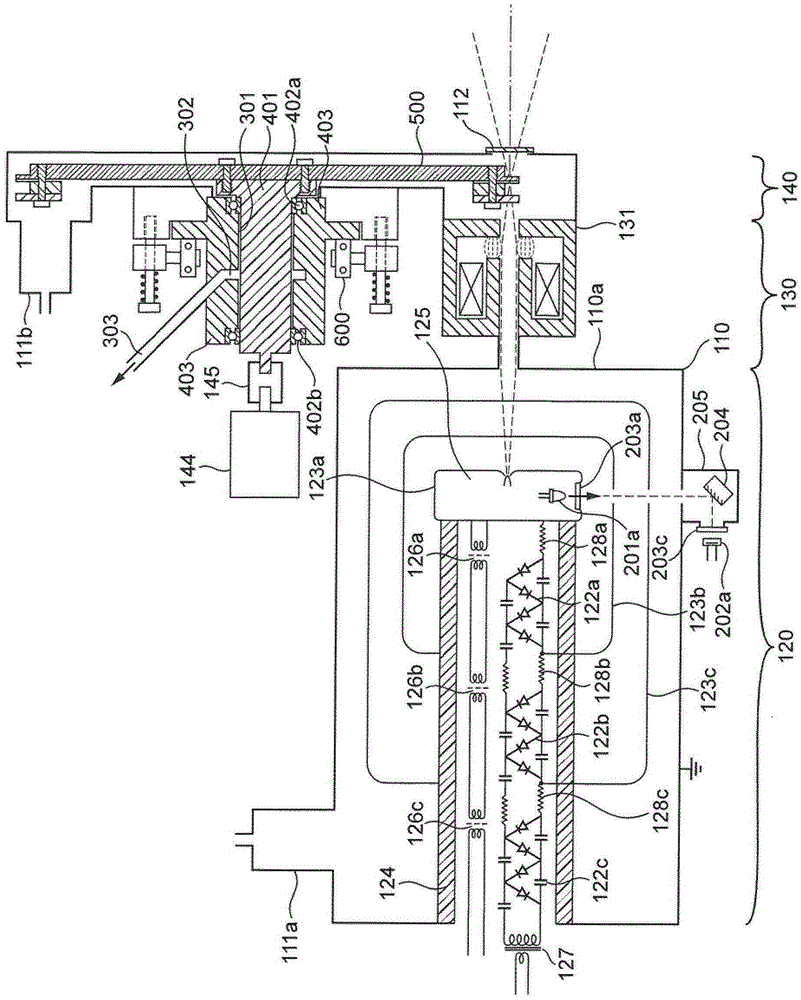

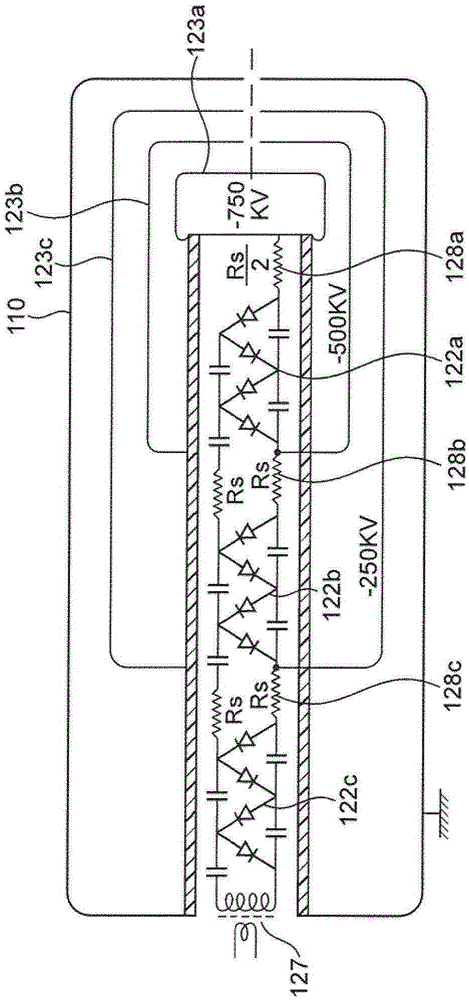

[0108] Basic structure and general principles

[0109] X-rays can be produced by irradiating a target composed of a material containing a large proportion of high atomic number atoms or ions with a suitable high energy electron beam. An electron beam is produced by accelerating electrons across a large potential difference and then directing the beam to a target. Electrons in the electron beam interact with the electric field of the high atomic number nuclei and emit x-ray photons through the process of bremsstrahlung. Thus, the generated x-rays have a continuum with an upper energy limit determined by the energy of the incident photon.

[0110] However, in the exemplary electron beam case of 100 keV, typically only 1% of the incident electron beam energy is converted to x-ray radiation; the remainder of the incident electron beam energy is deposited as heat in the target. Although the proportion of the beam energy that is converted to x-ray radiation increases with increasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com