Automatic sand discharging device and sand discharging method thereof

An automatic and sand-feeding technology, applied in foundry molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. Achieve the effect of reducing labor intensity, simple structure and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

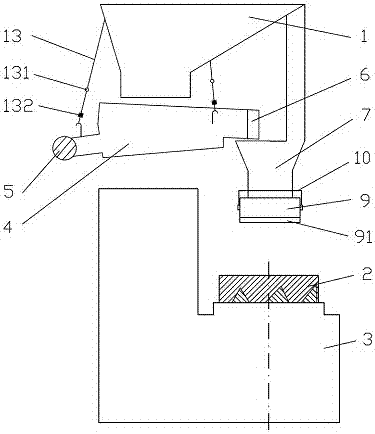

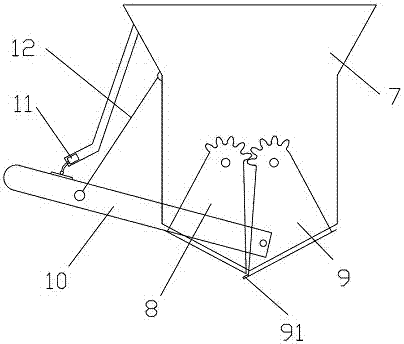

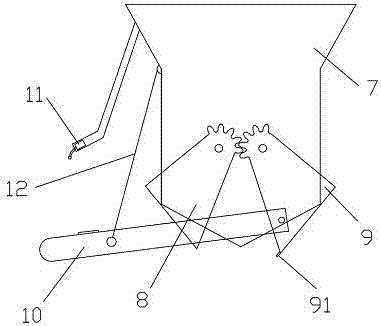

[0029] The invention discloses an automatic sand-discharging device and a sand-discharging method suitable for molding thin-walled small parts.

[0030] Such as Figure 1~Figure 3 As shown, it includes a sand storage bucket 1 for storing molding sand, a sand box 2 for product molding, and a molding table 3 for fixing the sand box 2. A mold for qualitative molding sand is also placed in the sand box 2. . It also includes a control mechanism for controlling the overall operation of the device, a sand delivery mechanism arranged under the sand storage bucket 1 for conveying molding sand, and a sand discharge mechanism arranged above the sand box 2 for sand discharge. The sand-discharging mechanism is set under the sand-feeding mechanism and matches with the sand-feeding mechanism, and the sand-feeding mechanism is suspended under the sand storage bucket 1 by means of a suspension assembly and matches with the sand storage bucket 1 , the sand discharging mechanism is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com