Combined turning tool

A technology for combining turning tools and turning tools, which is applied in the direction of tools used in lathes, turning equipment, tool holder accessories, etc., to achieve the effect of economical benefits, low prices, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

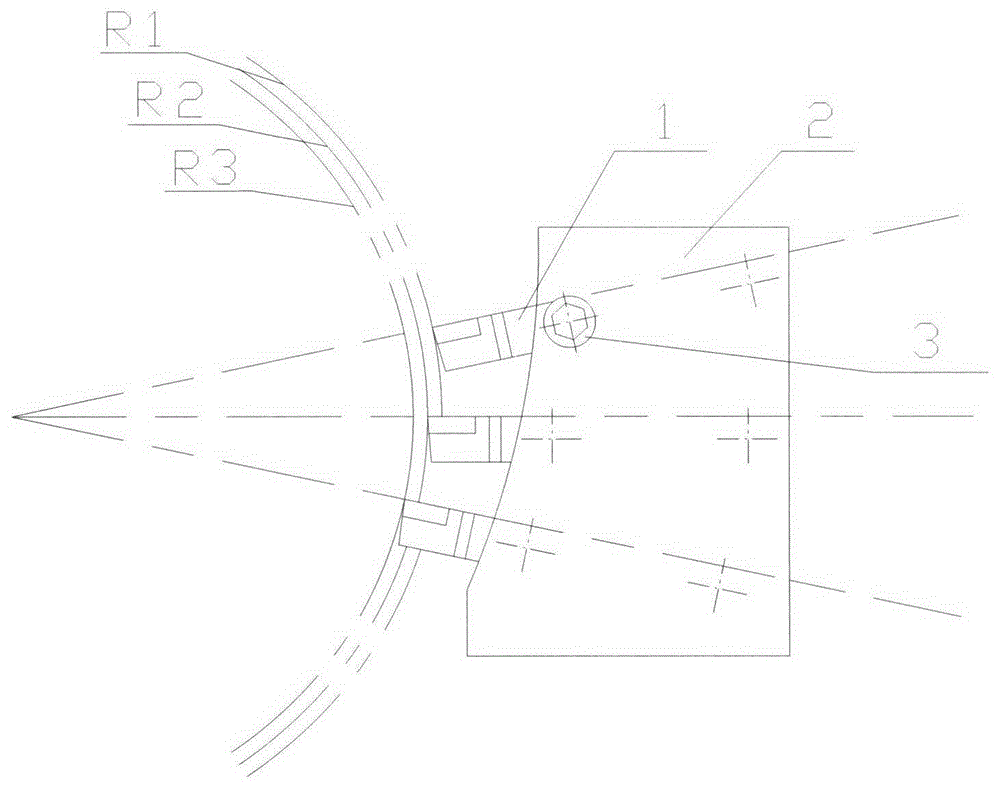

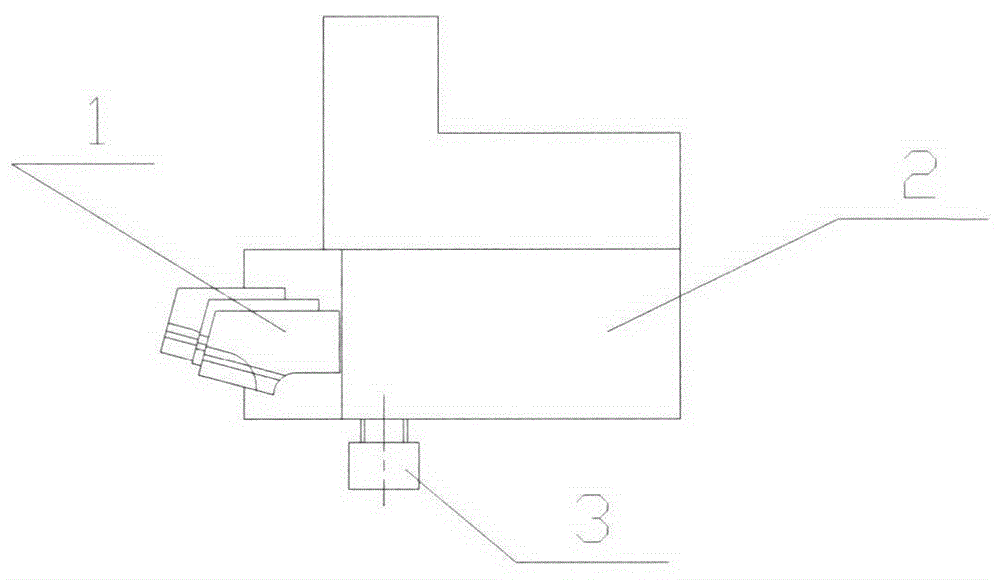

[0018] Combined turning tools include turning tools, tool holders and fastening screws (see figure 1 , figure 2 ), there are 3 square holes processed on the tool holder, which are arranged in a staggered upper and lower angle (see image 3 , Figure 4 , Figure 5 ). Clamp 3 turning tools in the square hole, the extension line of the blade of each turning tool points to the center of the workpiece, and the blade inclination angle is 0 degrees; the difference between the tip of adjacent turning tools and the center of the workpiece is 5mm, that is, the difference in machining radius is 5mm; the axis of adjacent turning tools The direction difference is 3 mm, that is, after the first turning tool cuts the axial length of 3 mm, the second turning tool enters the cutting again, and the cutting sequence is turning tool 1, turning tool 2, and turning tool 3.

[0019] The tool divides the original cutting depth into three, the cutting speed can be increased by more than 50%, and ...

Embodiment 2

[0021] There are 10 square holes processed on the combined turning tool holder, which are distributed in a staggered upper and lower angle. Hold 10 turning tools on the tool holder (see Image 6 , Figure 7 ), the extension line of each turning tool blade points to the center of the workpiece circle, and the blade inclination angle is 0 degrees; the machining radius difference of adjacent turning tools is 2.5 mm, and the axial difference is 2 mm. The cutting order is turning tool 1, turning tool 2, turning tool 3 To turning tool 10.

[0022] This combined turning tool can be used when machining super-large-diameter outer circles. The tool can decompose the original cutting depth into 10 small cutting depths, and the cutting speed can be increased by 200%, which greatly improves the processing efficiency.

Embodiment 3

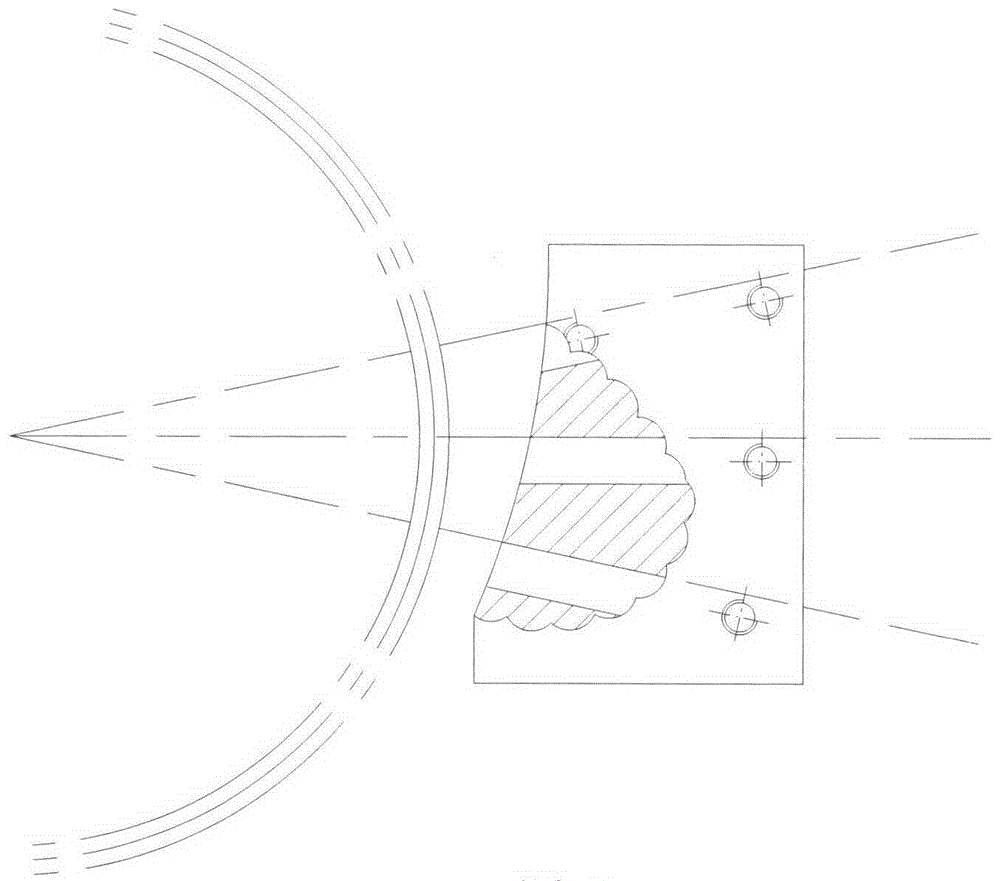

[0024] Figure 8 Figure 9 It is a combined turning tool for rough turning inner holes. Three turning tools are clamped on the tool holder, the extension line of each turning tool edge points to the center of the workpiece, and the blade inclination angle is 0 degrees; the difference between the machining radius of adjacent turning tools is about 2mm, and the axial difference is 2mm, that is, the first turning tool cuts 2mm After the axial length, the second turning tool enters the cutting again, and the cutting sequence is turning tool 1, turning tool 2, and turning tool 3.

[0025] The cutting depth of each turning tool of the cutting tool is one-third of that of one cutting tool, the cutting speed can be increased by more than 50%, and chips can be easily broken, and the cutting efficiency is obviously improved.

[0026] The number of combined turning tools for roughing the inner hole can also be more than three. When actually machining the inner hole, the number of turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com