A continuous steel cutting line

A continuous and assembly-line technology, applied in the field of cutting, can solve the problems of heavy workload, inability to realize continuous cutting, susceptibility to lumbar muscle strain, etc., and achieve low working cost, high cutting effect and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

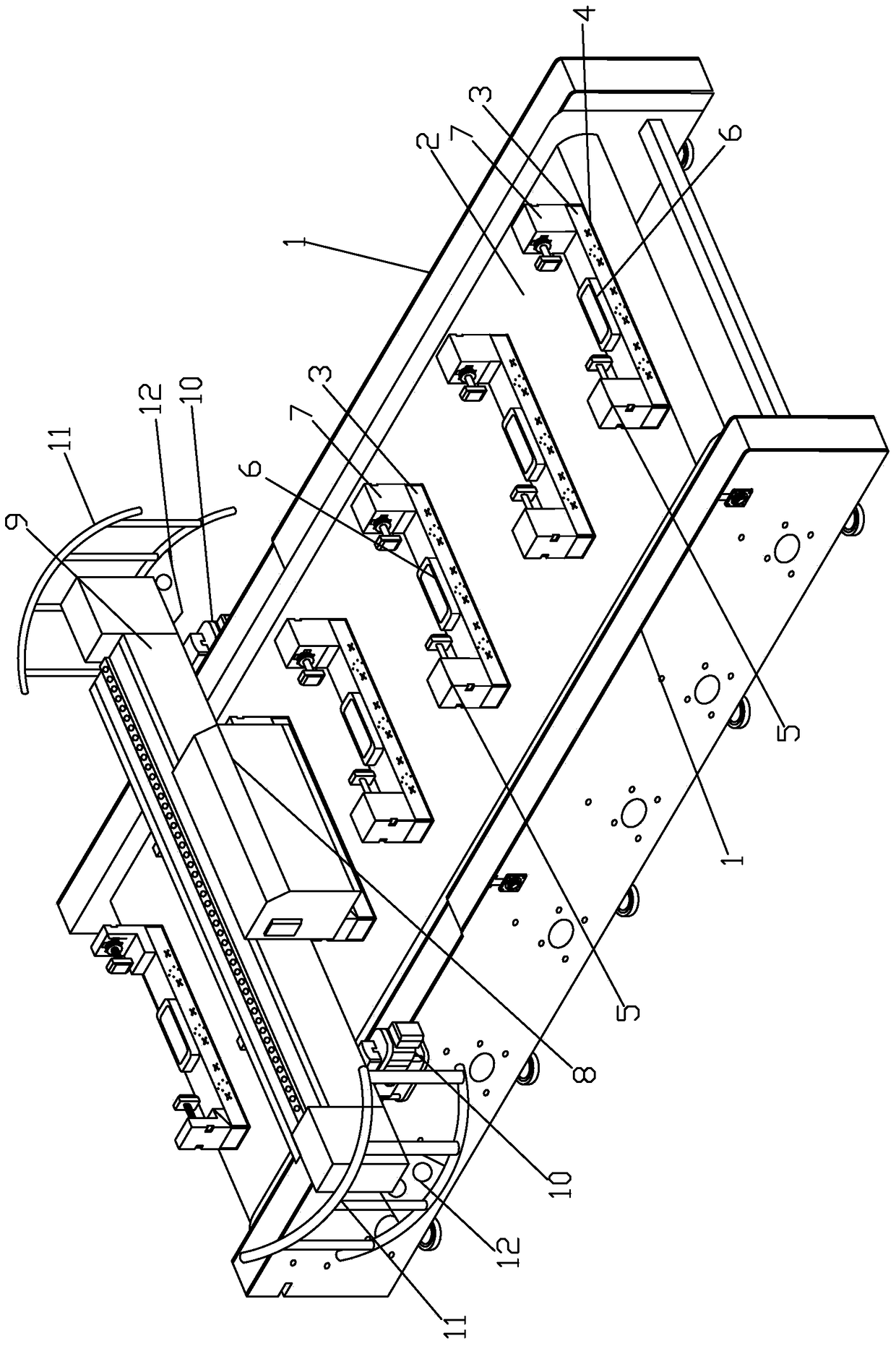

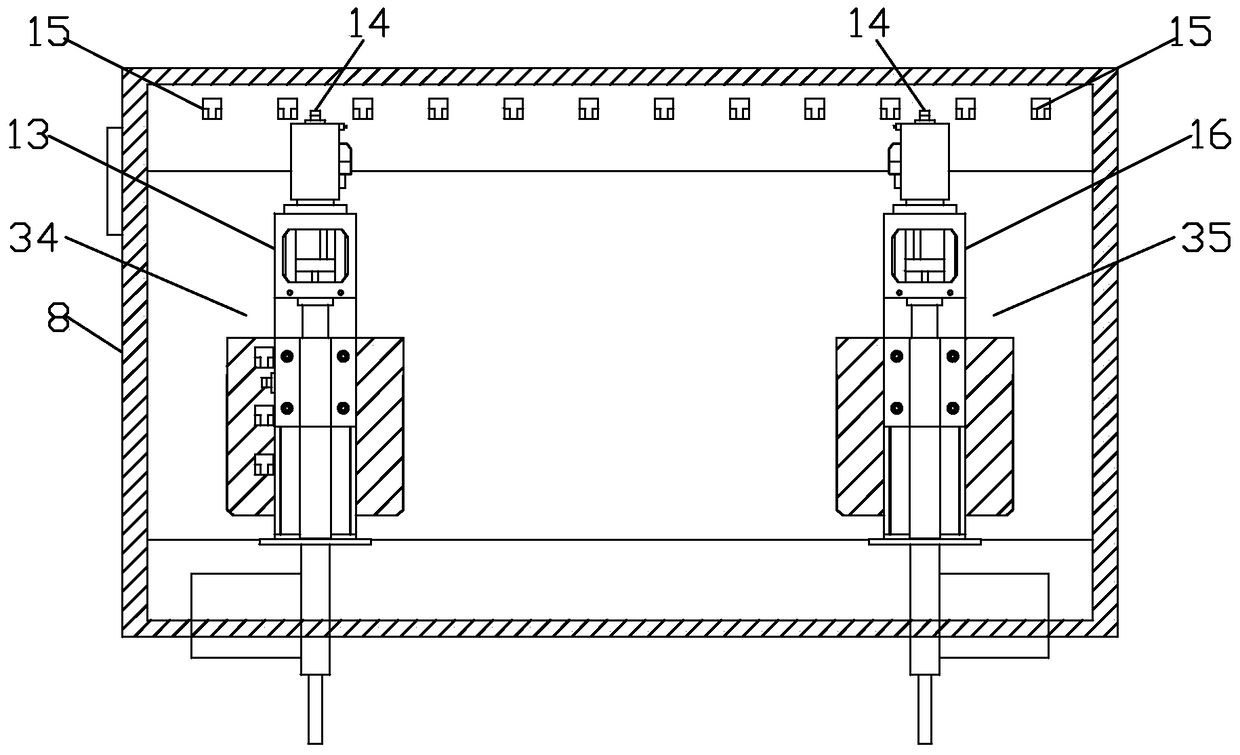

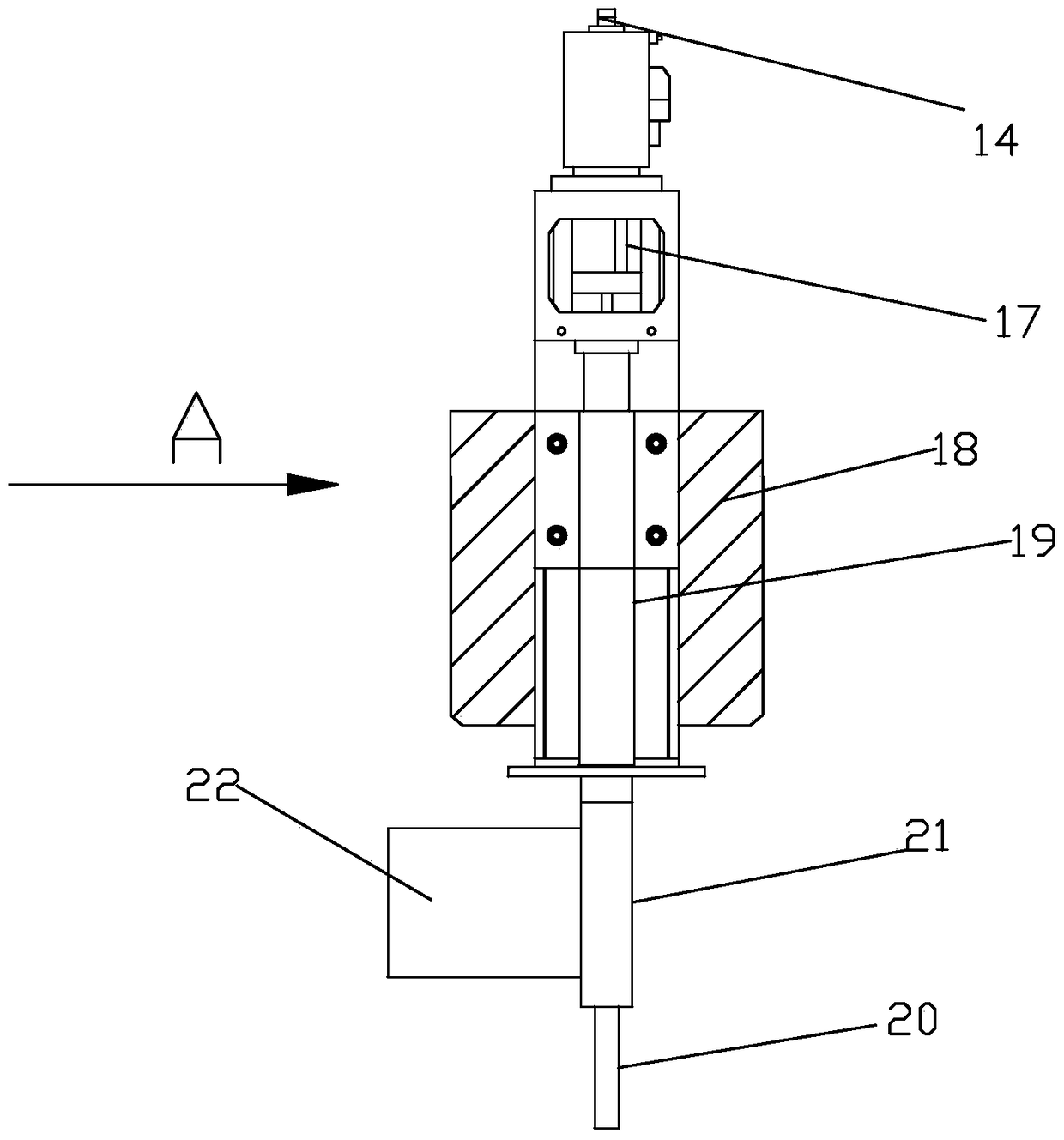

[0033] Such as Figure 1 to Figure 9 As shown, a continuous steel cutting assembly line includes a frame 1, a fixed seat, a cutting device 8 and a beam 9. The frame 1 is 10m long and 1.1m high. There are guide belts 2 and 2 guide belts between the frame 1. Driven by the motor, it can rotate, so that the steel workpiece on the fixed seat can be conveyed by the guide belt 2 at a constant speed, and the steel workpiece can be cut continuously during the conveying process. The cutting effect is high, and the number of steel workpieces that can be cut per unit time increases significantly, which is very suitable for factories Modernized production can bring huge economic and social benefits.

[0034] The guide belt 2 is connected with a fixed seat, which is evenly arranged on the guide belt 2, and the interval between adjacent fixed seats is 1m; the fixed seat includes a base 3, a tray 6 and a positioner, and the lower end of the base 3 is provided with a rubber gasket 4. The base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com