System for removing gear burrs

A technology of gears and burrs, applied to components with teeth, belts/chains/gears, gear teeth, etc., to achieve high economic benefits, ensure meshing performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

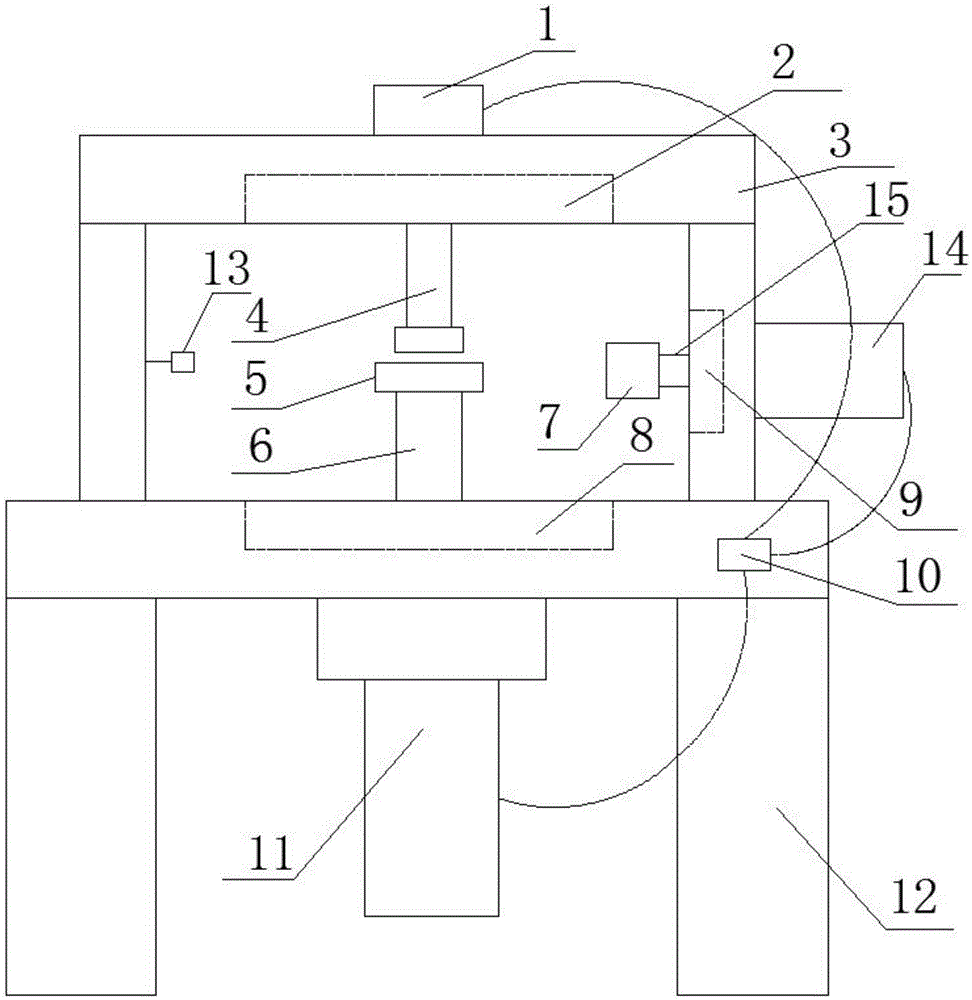

[0028] A system for removing burrs from gears. A device is designed that can be multi-linked to deal with burrs on the gear surface. The three-linkage control method can effectively remove the burrs on the gear surface without affecting the meshing performance of the gears. , has the characteristics of simple structure and high economic benefit, such as figure 1As shown, it is particularly arranged as the following structure: it is provided with an upper bracket system 3 and a lower bracket system 12, and the upper bracket system 3 is fixed on the upper platform of the lower bracket system 12; The gear rotation structure system 11, the rotation shaft 6 of the gear rotation structure system 11 runs through the upper table of the lower support system 12; the push structure system 1 is also arranged on the upper table of the upper support system 3, and the push structure system The rotating shaft 4 of 1 runs through the upper table of the upper bracket system 3, and the rotating ...

Embodiment 2

[0031] This embodiment is further optimized on the basis of the above embodiments. In order to better realize the present invention, it can flexibly control the pushing structure system according to the needs, so that it can move in the horizontal direction so that it can be connected with the brush The system and the gear rotation structure system can cooperate well to remove the burrs on the gears, such as figure 1 As shown, the following structure is particularly arranged: a moving cavity 2 for pushing the structural system 1 to move laterally is also arranged on the upper table. When in use, the pushing structure system 1 can be moved laterally in the moving cavity 2 according to actual needs, so that the brush system 14 can more conveniently remove burrs from the gear 5 .

Embodiment 3

[0033] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, it can flexibly control the gear rotation structure system according to the needs, so that it can move in the lateral direction, so that It cooperates well with the brush system and the push structure system to deburr the gears, such as figure 1 As shown, the following structure is particularly arranged: a cavity 8 for the lateral movement of the gear rotation structure system 11 is also provided on the upper table. During use, the gear rotating structure system 11 can be moved laterally in the cavity 8 according to actual needs, so that the brush system 14 can more conveniently remove burrs from the gear 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com