A scratch-resistant reinforced PP plastic and preparation method thereof

A scratch-resistant and scratch-resistant agent technology, applied in the field of scratch-resistant reinforced PP plastic and its preparation, can solve the problems of toughness, poor low temperature and aging resistance, easy combustion, and large molding shrinkage rate, and achieves a good comprehensive performance, the effect of improving scratch resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

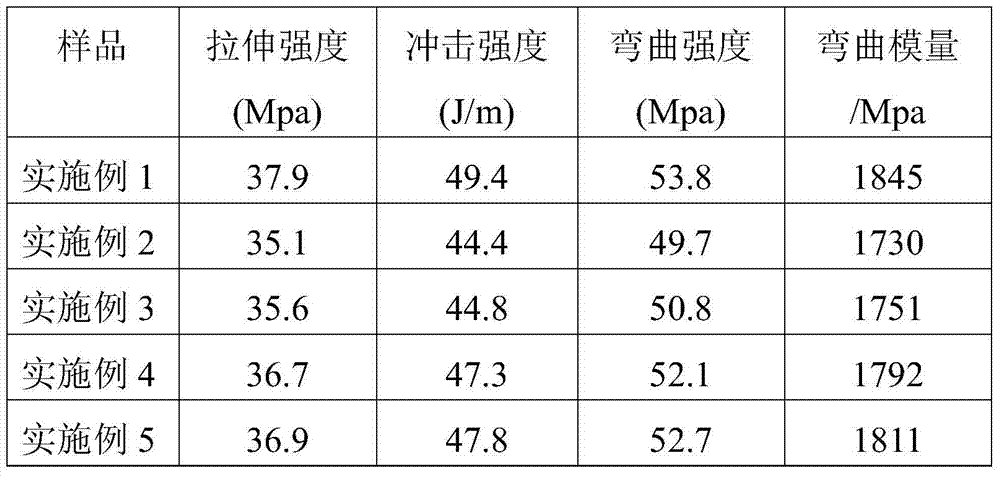

Examples

Embodiment 1

[0037] Weigh each raw material (parts by weight): 100 parts of PP resin, 2 parts of graphite, 2 parts of calcium stearate, 10 parts of silicon dioxide, 0.2 part of coupling agent, 0.4 part of scratch-resistant agent, and 0.3 part of ultramarine blue.

[0038] Described coupling agent consists of 0.1 part of 3-acryloyloxypropylmethyldimethoxysilane and 0.1 part of 3-[(2,3)-glycidyloxy]propylmethyldimethoxysilane mixed.

[0039] The scratch resistance agent is prepared by mixing 0.2 parts of N,N-dimethyldodecamide and 0.2 parts of N,N-diethyldodecamide.

[0040] (1) Silica modification: Stir the silica and the coupling agent in a high-speed mixer at a temperature of 80°C for 20 minutes and mix evenly to obtain modified silica;

[0041] (2) Mix the modified silica, PP resin, graphite, calcium stearate, anti-scratch agent, and ultramarine blue evenly, and add them to the twin-screw extruder. The processing temperature of the twin-screw extruder is 240°C. The rotation speed is 35...

Embodiment 2

[0043] Scratch-resistant reinforced PP plastics were prepared according to the raw material ratio and method of Example 1, except that the coupling agent was 0.2 parts of 3-acryloyloxypropylmethyldimethoxysilane. The scratch-resistant reinforced PP plastic of Example 2 was obtained.

Embodiment 3

[0045] Scratch-resistant reinforced PP plastics were prepared according to the raw material ratio and method of Example 1, the only difference being that the coupling agent was 0.2 parts of 3-[(2,3)-glycidyloxy]propylmethyl di Methoxysilane. The scratch-resistant reinforced PP plastic of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com