Active dye ink

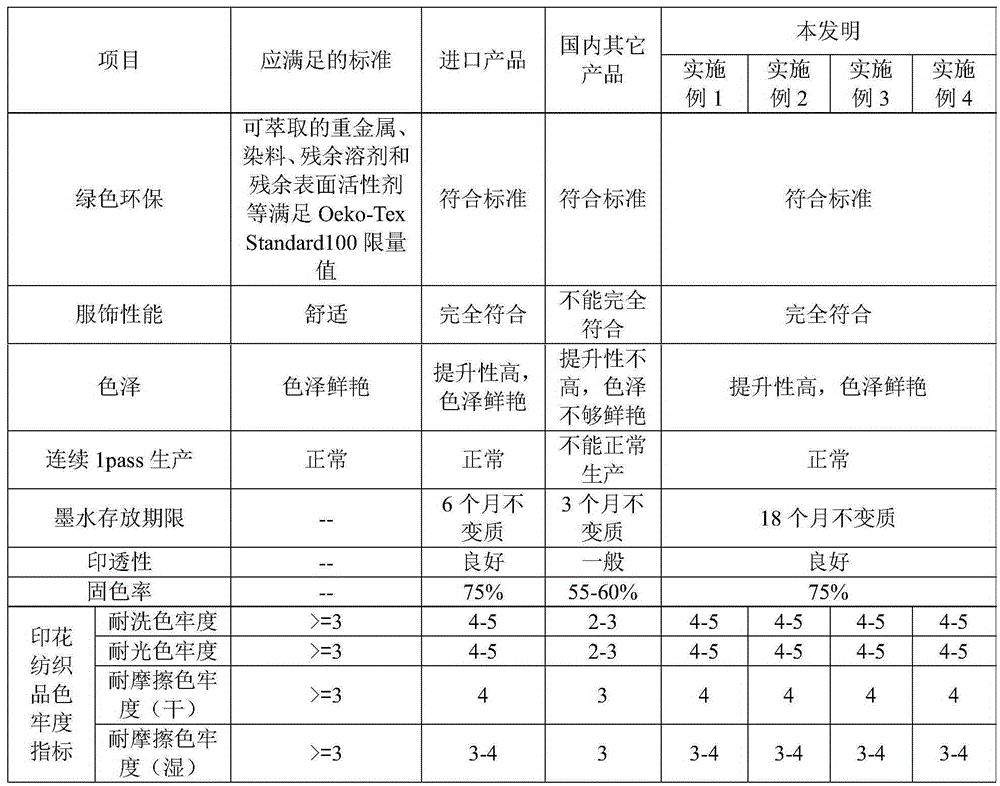

A technology of reactive dyes and inks, applied in ink, dyeing, textiles and papermaking, etc., can solve the problems of not bright fabric printing, clogged nozzle printing, poor printing penetration, etc., achieve bright colors, speed up popularization, and good printing and dyeing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

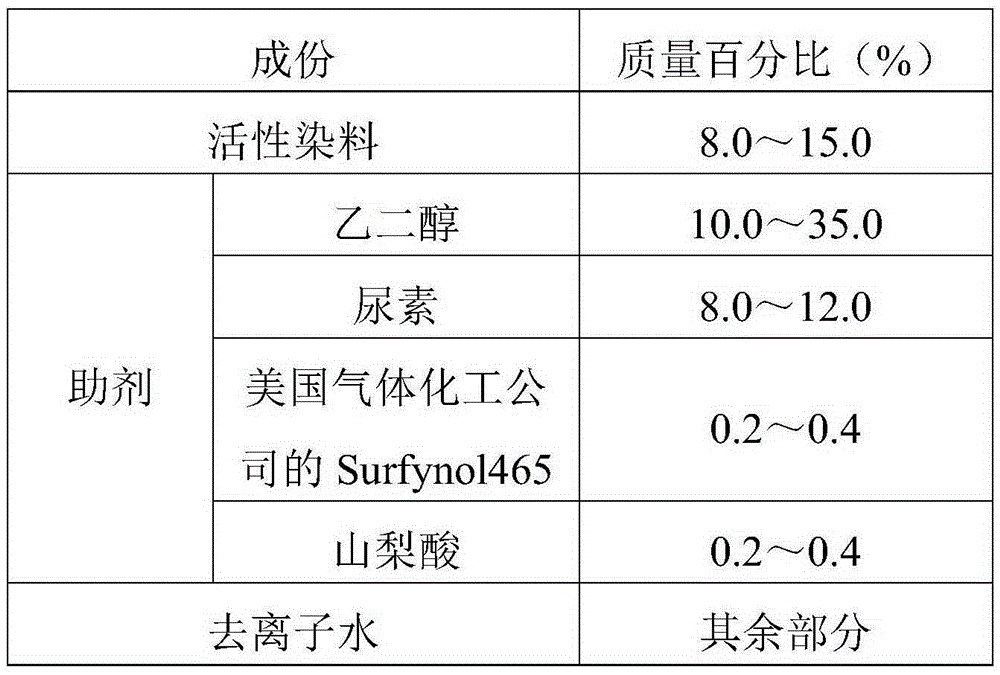

Method used

Image

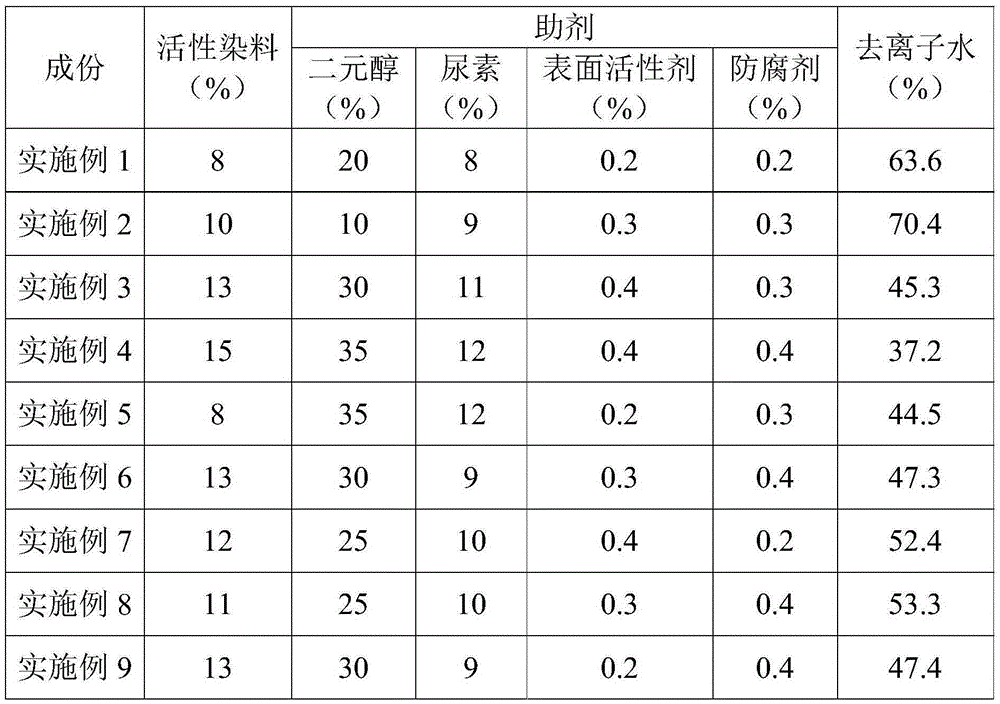

Examples

Embodiment 2

[0033] The reactive dye used in embodiment 2 is C.I. reactive blue 72, and dibasic alcohol is ethylene glycol, and surfactant is the Surfynol465 of U.S. Gas Chemical Company, and preservative is sorbic acid;

Embodiment 3

[0034] Reactive dye used in embodiment 3 is C.I. Reactive black 39 and C.I. Reactive brown 12, dihydric alcohol is ethylene glycol, and surfactant is the Surfynol465 of U.S. Gas Chemical Company, and preservative is sorbic acid;

Embodiment 4

[0035] The reactive dye used in embodiment 4 is C.I. Reactive Orange 13, and the glycol is ethylene glycol, and the surfactant is Surfynol465 of U.S. Gas Chemical Company, and the preservative is sorbic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com