A reactive stabilizer with dual functions of antioxidant and anti-yellowing agent for spandex

An anti-oxidant and anti-yellowing agent technology, applied in the direction of one-component polyurethane artificial filament, etc., can solve the problems of reduced performance and achieve the effect of small addition, simple structure and excellent efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

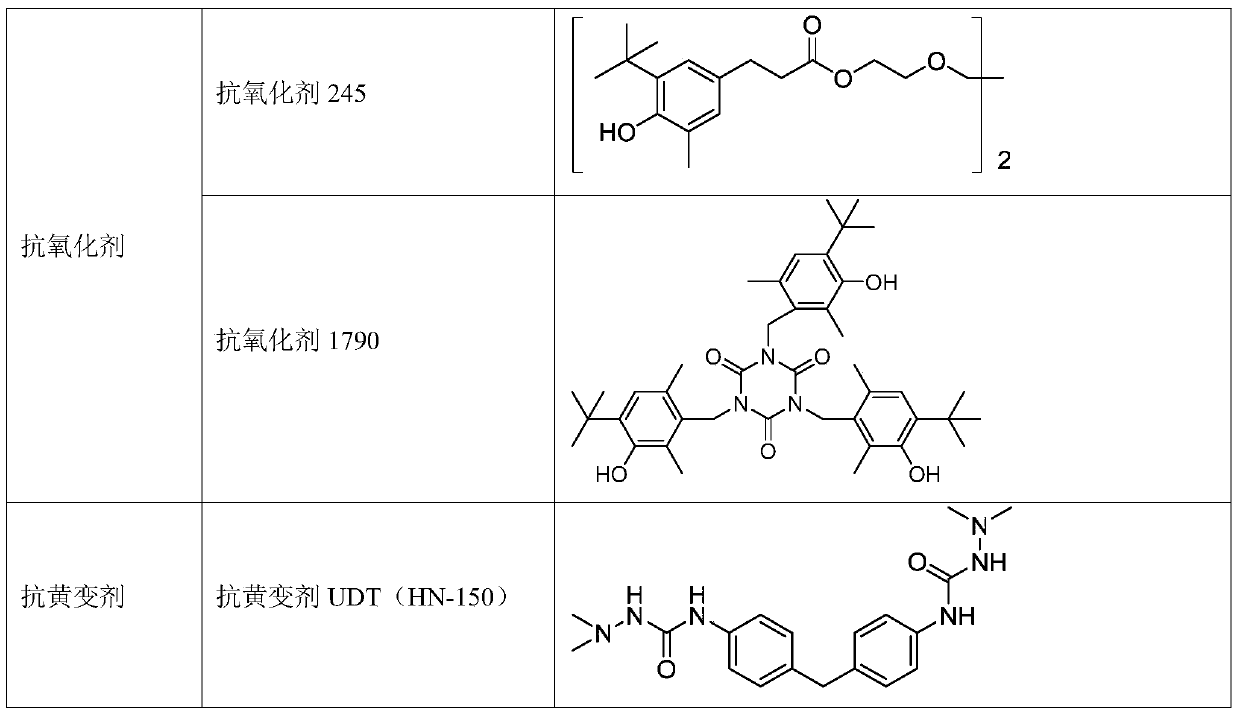

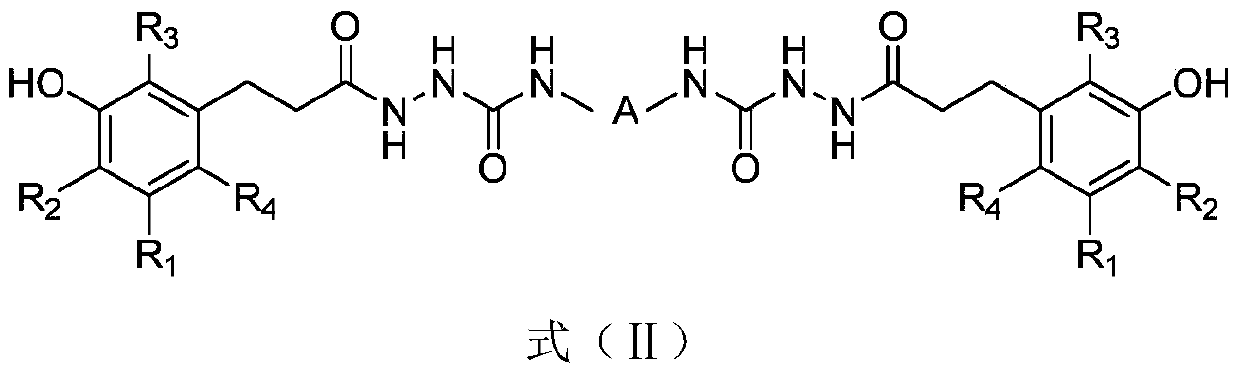

Method used

Image

Examples

example 1

[0038] Mix 1mol polyether polyol (PTMEG, molecular weight 2000±100) with 2mol diphenylmethane diisocyanate (MDI), prepolymerize at 80-90°C, cool the prepolymer to 52-55°C, add N,N-dimethylacetamide (DMAC) becomes a solution with a solid content of 45%, then adds ethylenediamine and cyclohexanediamine as a chain extender, and then adds 0.2% or 0.5% (relative to the polyurethane resin weight % ) containing DMAC solution of structural formula 1 stabilizer 3,5-di-tert-butyl-4-hydroxyphenylpropionohydrazide 20% (% by weight) of the present invention, reacted for 10-15min, and ended with diethylamine as an end-capping agent Polymerization. The DMAC solution of the obtained polyurethane contains about 32% of the polyurethane resin.

[0039] The viscous liquid is coated on a flat glass to form a film. The resulting film 1# and film 2# were subjected to thermo-oxidative aging in an oven at 100°C for 10 days, placed indoors for 60 days, and tested for ΔE values in the NOx test for 1...

example 2

[0041] Carry out the same operation as example 1, only the stabilizer of structural formula 1 of the present invention is replaced with the stabilizer 3-methyl-5-tert-butyl-4-hydroxyphenylpropionylhydrazide of structural formula 2 of the present invention, so as to contain 30 % (weight %) 3-methyl-5-tert-butyl-4-hydroxyphenylpropionohydrazide was added in the form of DMAC solution, and the addition amount was 0.2% or 0.4% (relative to the polyurethane resin weight %) to obtain film 3 #和film4#.

[0042] As in Example 1, the ΔE value was measured in a 100°C oven for 10 days by thermo-oxidative aging, placed indoors for 60 days, and NOx test for 1 hr. The test results are listed in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com