Seepage-proofing bearing structure of soft soil pressure tunnel

A bearing structure and pressure technology, applied in the field of tunnel engineering, can solve the problems of complex lining concrete formwork and pouring process, long construction period of prestressed lining, high construction requirements, etc., achieve obvious social and economic benefits, shorten construction period, airtight good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. Meanwhile, by way of explanation, the advantages of the present invention will become clearer and easier to understand.

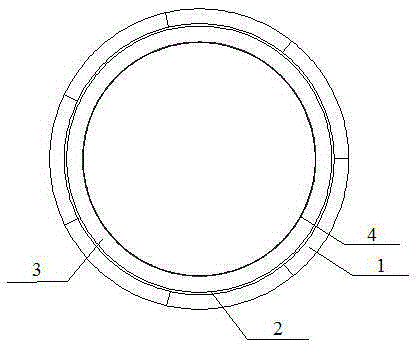

[0019] like figure 1 As shown, a composite lining carbon fiber cloth anti-seepage load-bearing structure of soft soil pressure tunnel includes: the assembled segment ring formed by shield tunneling method is a reinforced concrete outer lining 1, and a waterproof and drainage cushion 2 is laid on the inner surface of the reinforced concrete outer lining 1. Directly pour concrete on the inner surface of the waterproof and drainage cushion to form a reinforced concrete lining 3, and paste one or several layers of carbon fiber cloth 4 on the entire section of the inner surface of the reinforced concrete lining.

[0020] Concrete construction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com