A fuel tank isolation solenoid valve

A technology of solenoid valves and solenoid valve components, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as increased system complexity, difficult control of spring cumulative errors, and poor consistency of spring machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

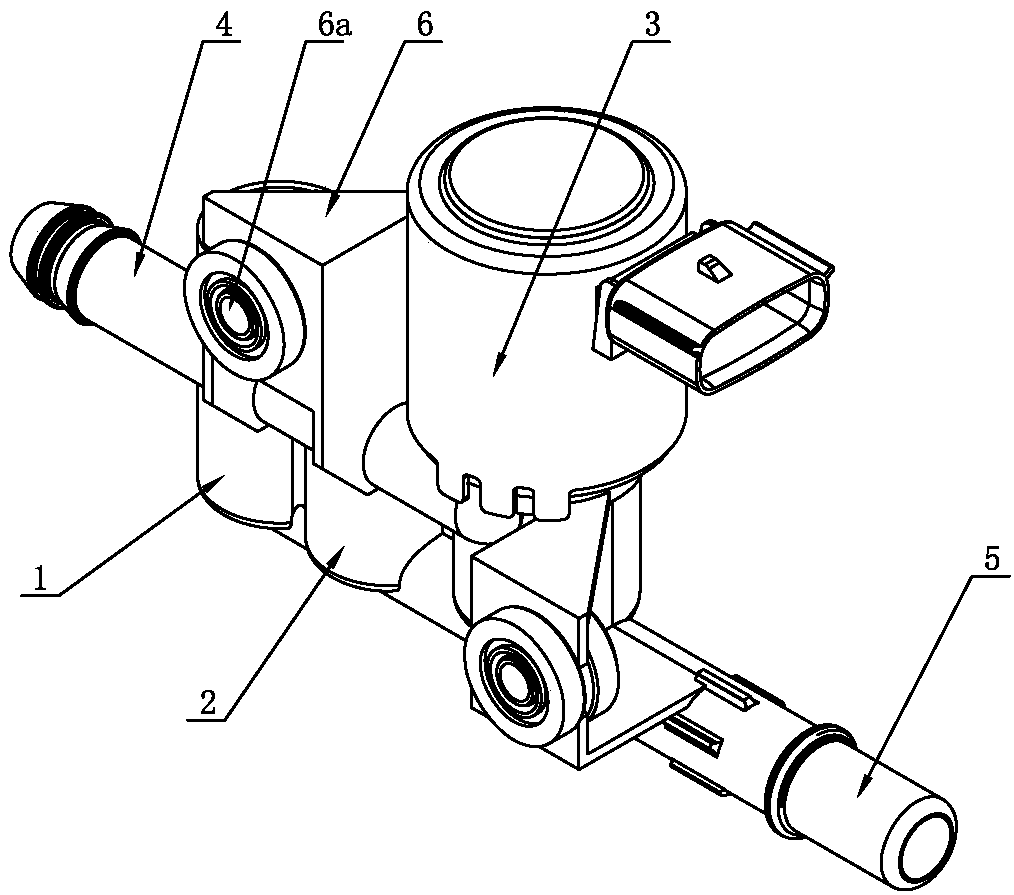

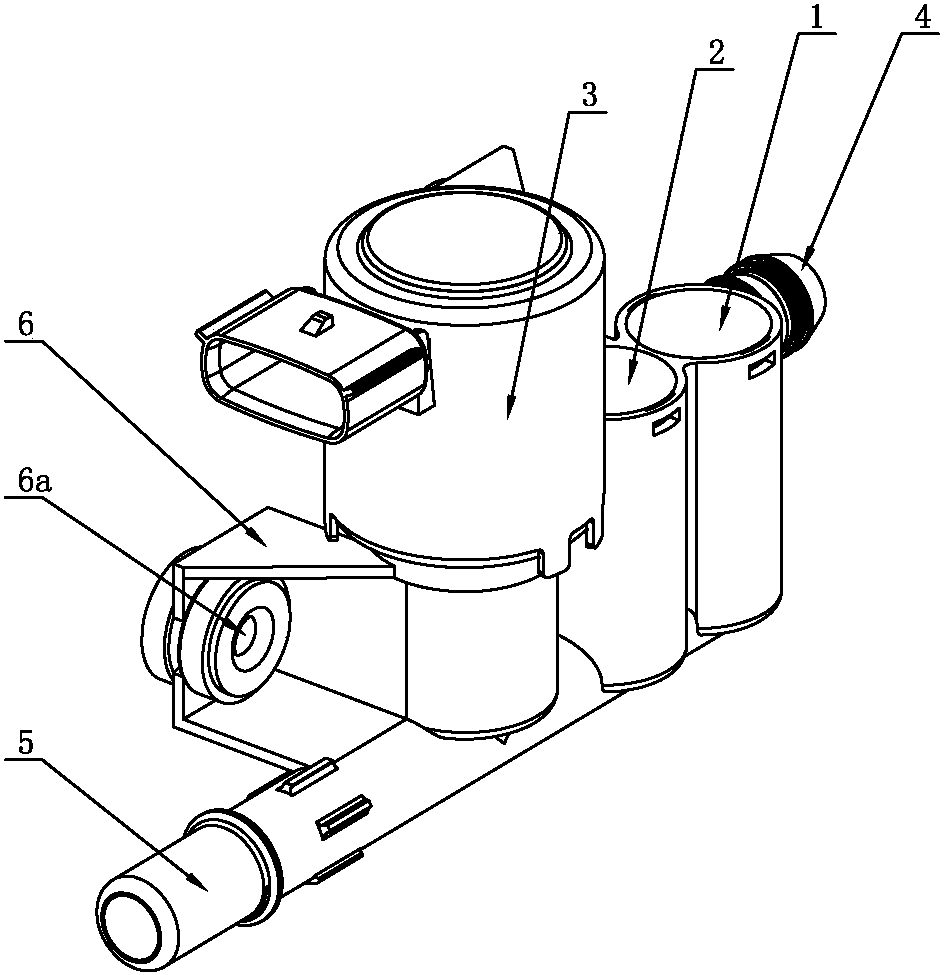

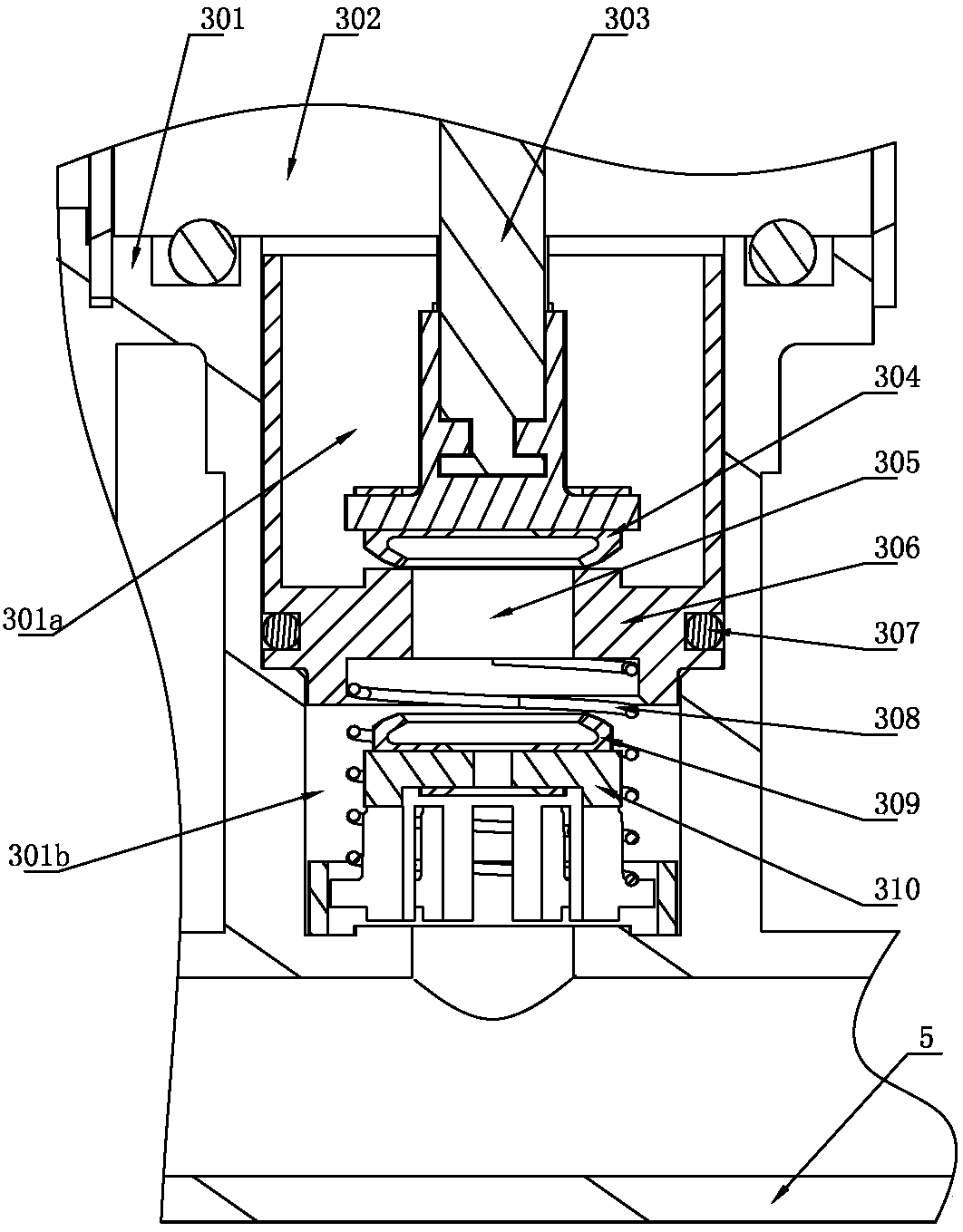

[0023] Such as Figure 1-4 A fuel tank isolation solenoid valve shown includes a fuel tank pipeline 5, a solenoid valve assembly 3, an air release valve assembly 1, an air supply valve assembly 2, and a carbon tank pipe 4, a valve body 301 of the solenoid valve assembly 3, and a valve body 301 of the air release valve assembly 1. The shell and the air supply valve assembly 2 are integrally formed. The bottoms of the solenoid valve assembly 3, the air release valve assembly 1, and the air supply valve assembly 2 are all connected to the fuel tank pipeline 5 to form a gas path communication. The solenoid valve assembly 3. The upper parts of the air release valve assembly 1 and the air supply valve assembly 2 are connected to the carbon tank pipeline 4 and form a gas path communication. The solenoid valve assembly 3, air release valve assembly 1, and air supply valve assembly 2 are connected to each other The casings are connected together; the solenoid valve assembly 3 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com