LED module light source

A technology of LED modules and LED chips, which is applied in the direction of electric light sources, semiconductor devices, lighting and heating equipment, etc., can solve problems such as fracture, low mechanical strength of bonding wires, internal stress damage of packaging colloid, etc., and achieve the elimination of internal stress, Excellent light extraction effect, avoiding shear stress and elastic modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

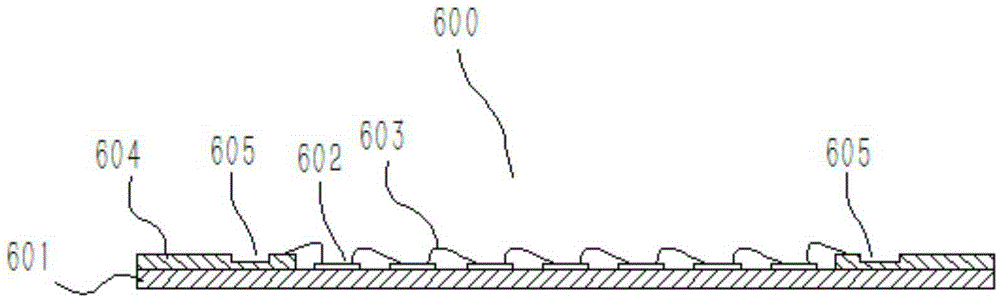

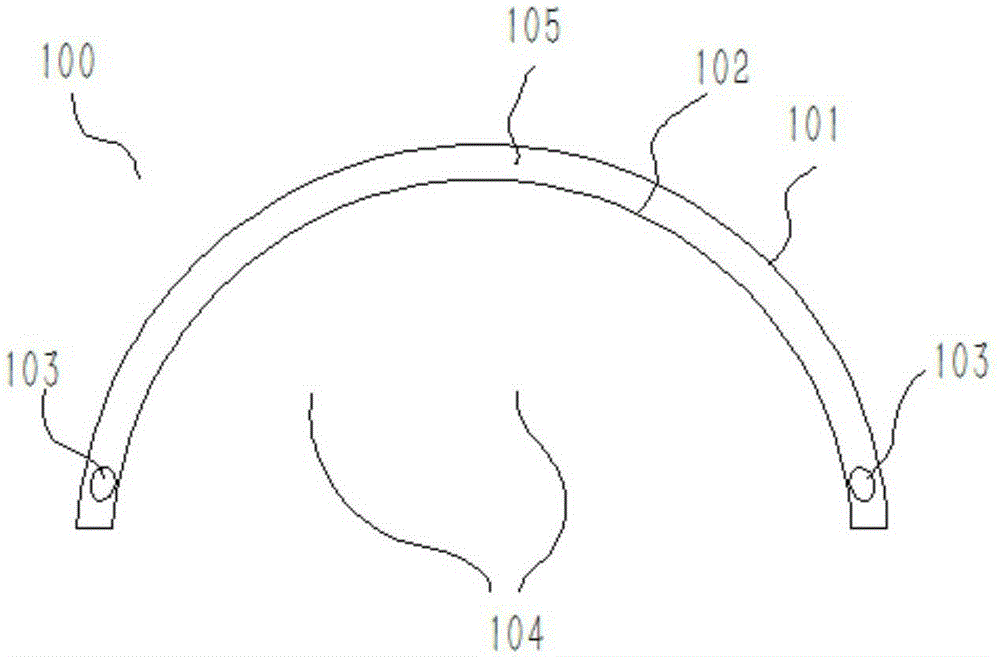

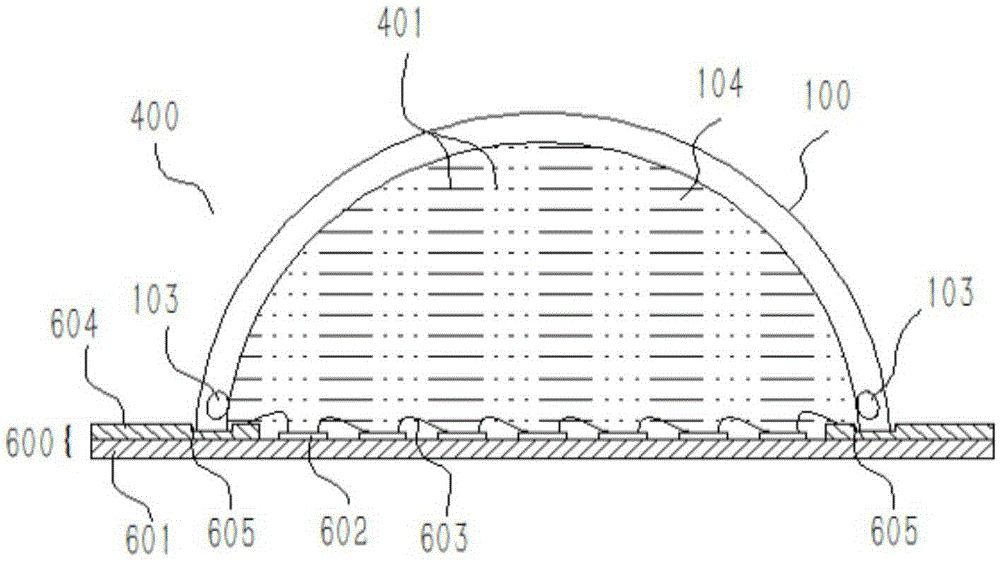

[0040] Such as Figure 2-4 As shown, the lens 100 is installed on the base 600 , and the opening edge of the lens 100 is butted and glued to the installation groove 605 of the base 600 .

[0041] The lens 100 includes a filling cavity 104 , the filling cavity 104 forms a closed space with the substrate 601 , and the first filler 401 is filled in the closed space. The first filler 401 is a colorless, transparent non-solid substance, and is non-conductive, thereby avoiding the shear stress and elastic modulus in the traditional solid potting glue, and completely eliminating the thermal loss caused by different packaging materials. The combination acts on the internal stress of the bonding wire, which greatly improves the long-term reliability of the bonding wire, thereby reducing the harsh requirements of the reliability of the package on the material system and packaging technology. The LED chip 602 and the bonding wire 603 are located in the enclosed space.

[0042] The lens...

Embodiment 2

[0053] The technical scheme of this embodiment and embodiment 1 is basically the same, and its difference mainly lies in:

[0054] The structure of the lens 200 of this embodiment is different from that of the lens 100 in Embodiment 1, wherein, as Figure 5 As shown, the inner surface 202 and the outer surface 201 of the lens body 205 in this embodiment are curved surfaces, and its cross-sectional view is wavy.

Embodiment 3

[0056] The technical scheme of this embodiment and embodiment 1 is basically the same, and its difference mainly lies in:

[0057] The structure of the lens 300 in this embodiment is different from that of the lens 100 in Embodiment 1 and the lens 200 in Embodiment 2, wherein, as Figure 6 As shown, the inner surface 302 of the lens body 305 in this embodiment is a curved surface, specifically as Figure 6 It is a curved surface, and the outer surface 301 is a serrated plane.

[0058] It should be noted that the structure of the lens of the present invention includes but not limited to the three structures described in Embodiments 1, 2 and 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com