Variable parameter liquid-absorbing core ultra-thin heat pipe

A technology of ultra-thin heat pipes and liquid-absorbing cores, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficult-to-work substance circulation process, restrict reflux of condensed liquid, and difficult to design performance capillary liquid-absorbing cores, etc. Achieve the effect of improving comprehensive performance and optimizing the gas-liquid circulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

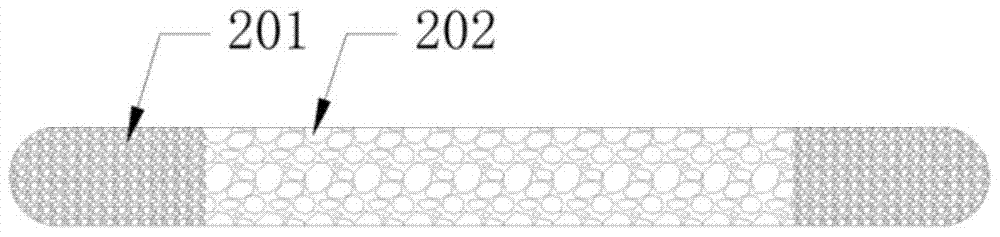

[0033] The variable-parameter liquid-absorbing core ultra-thin heat pipe of this embodiment includes a heat pipe shell, a liquid-absorbing core, and a heat pipe working medium. The liquid-absorbing core is made of porous copper foam material, the overall thickness is 0.5mm, the width is 5mm, and the length is 80mm. In the width direction, the parameters of the porous copper foam on the left and right sides are the average pore diameter of 1um, the porosity of 90%, the size of the occupied width direction is 1mm, the width of the liquid-absorbing core in the middle part is 3mm, the average pore diameter is 100um, and the porosity 80%, the width of the transitional part connecting the two regions shall not exceed 0.5mm. The heat pipe shell uses TU1 material The thin-walled copper tube is flattened. After flattening, the wall thickness of the heat pipe is 0.5mm, the width of the heat pipe is 9.7mm, the height of the middle cavity is 0.5mm, and the overall thickness is 1.5mm. Pu...

Embodiment 2

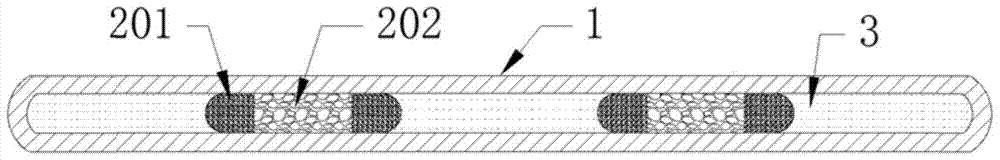

[0035] The variable-parameter liquid-absorbing core ultra-thin heat pipe of this embodiment includes a heat pipe shell, a liquid-absorbing core, and a heat pipe working medium. The liquid-absorbing core is made of sintered porous foam silver material, and two pieces are arranged side by side to form a "U"-shaped structure. The overall thickness of the capillary core is 0.6mm, the width is 15mm, and the length is 60mm. In the width direction, the parameters of the porous silver foam on the left and right sides of a single liquid-absorbing core are the average pore diameter of 1um, the porosity of 90%, the dimensions occupied in the width direction are 1mm each on the left and right, and the width of the liquid-absorbing core in the middle part is 3mm. The pore diameter is 50um, the porosity is 60%, and the width of the transition part connecting the two regions is not more than 0.5mm. The heat pipe shell uses TU1 material The thin-walled copper tube is flattened. After flatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com