Instant heating pipe

A heating tube, instant heating technology, applied in the field of heating tubes, can solve the problems of small contact area and poor heating effect, and achieve the effects of reasonable and simple structure, improved heating efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

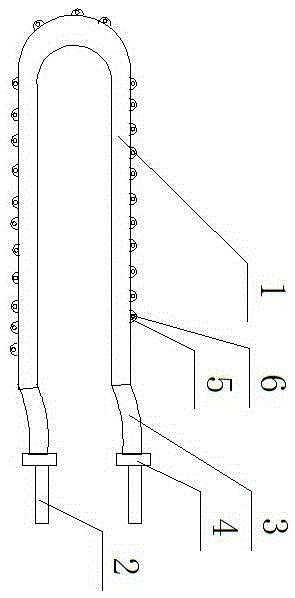

[0014] An instant heating tube, comprising a heating tube 1 and a joint 2, the heating tube 1 adopts a U-shaped design, the heating tube 1 is provided with several protrusions 5, and the protrusions 5 are provided with through holes 6, and the heating tube 1 The bottom end is provided with an extension pipe 3 , the bottom end of the extension pipe 3 is connected with an insulator 4 , and the insulator 4 is connected with the joint 2 . The insulator 2 is a flange made of quartz material. The tank body material of the heating tube 1 is copper or stainless steel. The height of the protrusion 5 is 1 mm.

Embodiment 2

[0016] An instant heating tube, comprising a heating tube 1 and a joint 2, the heating tube 1 adopts a U-shaped design, the heating tube 1 is provided with several protrusions 5, and the protrusions 5 are provided with through holes 6, and the heating tube 1 The bottom end is provided with an extension pipe 3 , the bottom end of the extension pipe 3 is connected with an insulator 4 , and the insulator 4 is connected with the joint 2 . The insulator 2 is a flange made of quartz material. The tank body material of the heating tube 1 is copper or stainless steel. The height of the protrusion 5 is 3 mm.

Embodiment 3

[0018] An instant heating tube, comprising a heating tube 1 and a joint 2, the heating tube 1 adopts a U-shaped design, the heating tube 1 is provided with several protrusions 5, and the protrusions 5 are provided with through holes 6, and the heating tube 1 The bottom end is provided with an extension pipe 3 , the bottom end of the extension pipe 3 is connected with an insulator 4 , and the insulator 4 is connected with the joint 2 . The insulator 2 is a flange made of quartz material. The tank body material of the heating tube 1 is copper or stainless steel. The height of the protrusion 5 is 5 mm.

[0019] In the present invention, in specific design, the extension pipe 3 can be designed in various shapes according to actual needs, so as to meet various installation requirements. At the same time, the number of through holes 6 on the protrusion 5 is not limited to one, but can be two, three or even multiple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com