High-speed printed circuit board and difference wiring method therefor

A high-speed printing, differential line technology, applied in the directions of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve problems such as the inability to meet high-speed signal quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below:

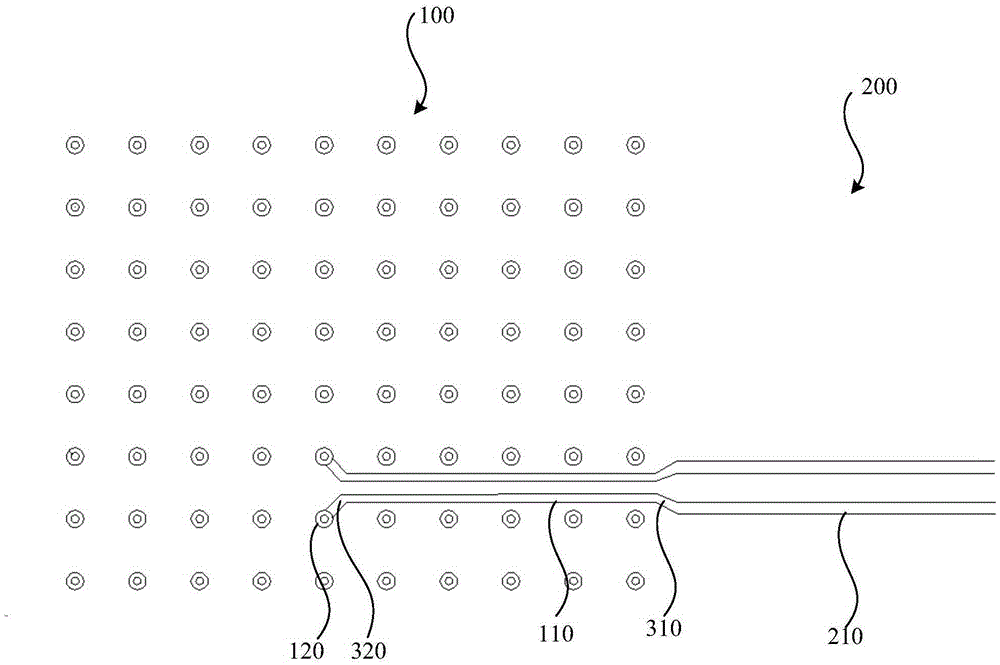

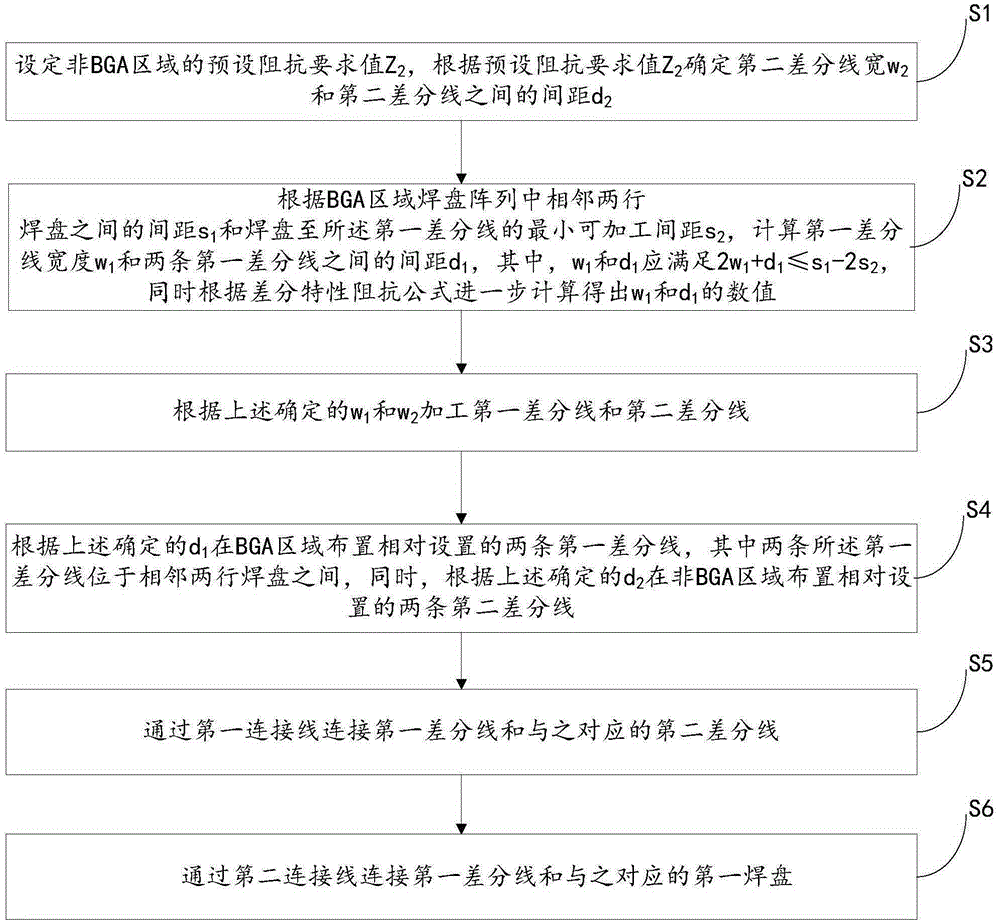

[0039] Such as figure 1 As shown, a high-speed printed circuit board at least includes sequentially stacked wiring layers, dielectric layers (not identified in the drawings) and shielding layers (not identified in the drawings). The wiring layer includes a BGA area 100 , a non-BGA area 200 and two differential transmission lines oppositely arranged. The two differential transmission lines both include a first differential line 110 located in the BGA area 100, a second differential line 210 located in the non-BGA area 200, and a first connection line 310 connecting the first differential line 110 and the second differential line 210 . The width of the first differential line 110 is smaller than the width of the second differential line 210 , and the distance between the two first differential lines 110 is smaller than the distance between the two second differential lines 210 . The width of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com