Work glove and manufacturing process thereof

A kind of labor protection gloves and manufacturing technology, which is applied in the direction of gloves, clothing, protective clothing, etc., can solve the problems of not holding tools and equipment tightly, fingers and palms that are difficult to bend and make fists, and injuries, so as to protect muscles, improve impact resistance, and reduce The effect of muscle soreness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

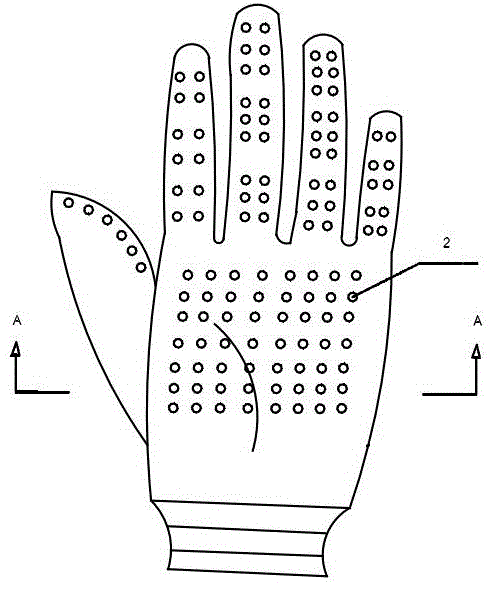

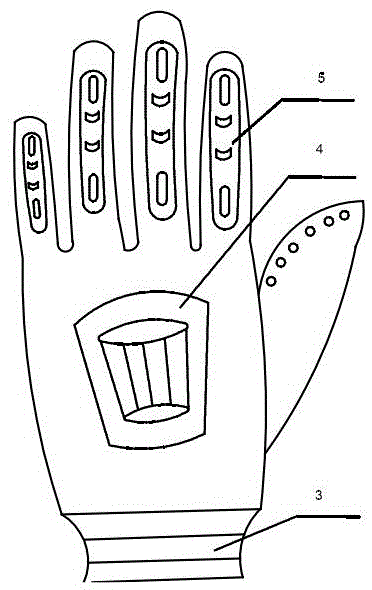

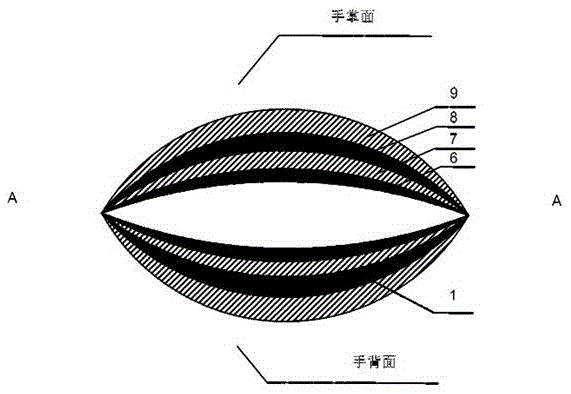

Embodiment 1

[0039] The palm surface of the labor protection gloves includes a base layer 6, a first coating layer 7, a palm functional layer 8 and a second coating layer 9 from the inside to the outside; the back of the hand includes the base layer 6 and the first coating layer 7 from the inside to the outside. 1. The back of the hand functional layer 1 and the second coating 9 are formed. Cotton fiber, carbon fiber and acrylic fiber are blended to make a braided thread, and the braided thread is used to weave the base layer 6; the first coating 7 is made of acrylonitrile-butadiene rubber, the surface is frosted, and the thickness is 0.3cm; the palm function Layer 8 is made of impact-resistant composite material, which uses carbon fiber and TPE to make a hexagonal honeycomb structure. The side length of this material is 0.3cm, and the height is 0.7cm. The honeycomb is filled with ethylene-propylene rubber, and the height of the filled ethylene-propylene rubber is The upper surface of the ...

Embodiment 2

[0047] The palm surface of the labor protection glove consists of a base layer 6, a first coating layer 7, a palm functional layer 8 and a second coating layer 9 from the inside to the outside; The functional layer 1 and the second coating 9 are formed. Cotton fiber, carbon fiber and polytetrafluoroethylene fiber are blended to make a braided wire, and the braided wire is used to weave the base layer 6; the first coating 7 is made of styrene-butadiene rubber, the surface is frosted, and the thickness is 0.2cm; The palm functional layer 8 is a shock-absorbing layer, and the shock-absorbing layer is made of sponge. The thickness of this layer is 0.8cm, and it is set as an integral structure at the same time, which is easy to form; the described functional layer 1 on the back of the hand is a refractory layer; The second coating 9 is made of silicone rubber, and the thickness is 0.4cm. The non-joint parts of the five fingers and the center of the palm of the second coating on the...

Embodiment 3

[0055] The palm surface of the labor protection glove consists of a base layer 6, a first coating layer 7, a palm functional layer 8 and a second coating layer 9 from the inside to the outside; The functional layer 1 and the second coating 9 are formed. Wherein the base layer 6 is made of acrylic fiber and cloth splicing and sewing; the first coating 7 is made of SBS, the surface is frosted, and the thickness is 0.4cm; the palm functional layer 8 is made of impact-resistant composite material, The material uses graphite fiber and TPO to make a circular structure. The thickness of the material is 1.5cm, and it is set as a split structure, which is easy to fit and process; Made of rubber; the second coating 9 is made of latex with a thickness of 0.5cm. The non-joint and palm positions of the five fingers of the second coating on the palm surface are provided with the anti-slip points 2, and the second coating on the back of the hand The second coating is provided with the decor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com