A milling cutter for processing steam turbine blade fir tree-shaped blade root and its design method

A steam turbine blade and design method technology, applied in metal processing equipment, milling cutters, milling machine equipment, etc., can solve the problems of short service life, surface quality decline, and low cutting efficiency of cutting tools, so as to prolong service life and reduce cutting Resistance and the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

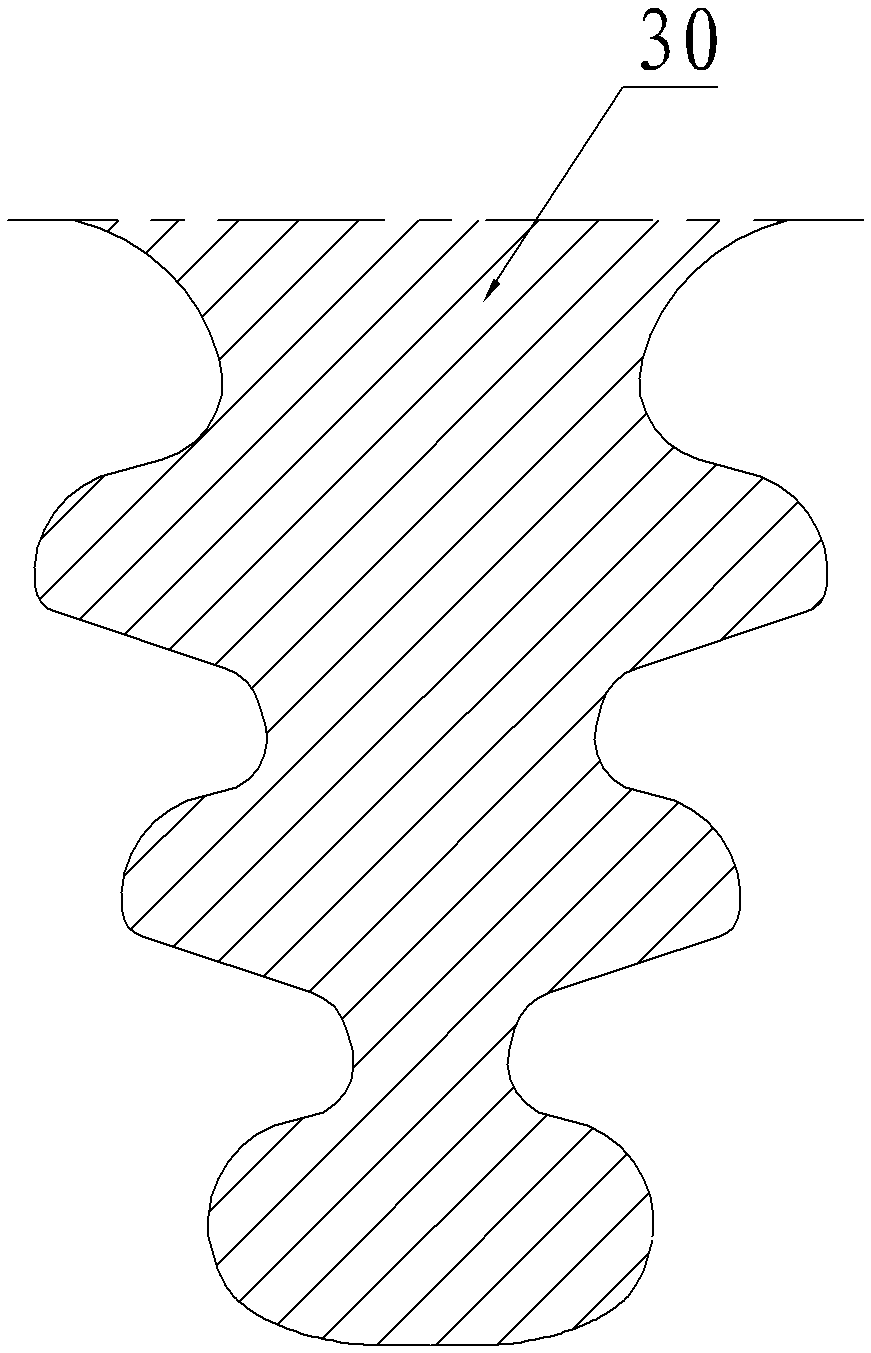

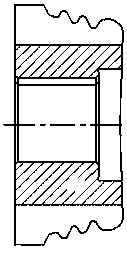

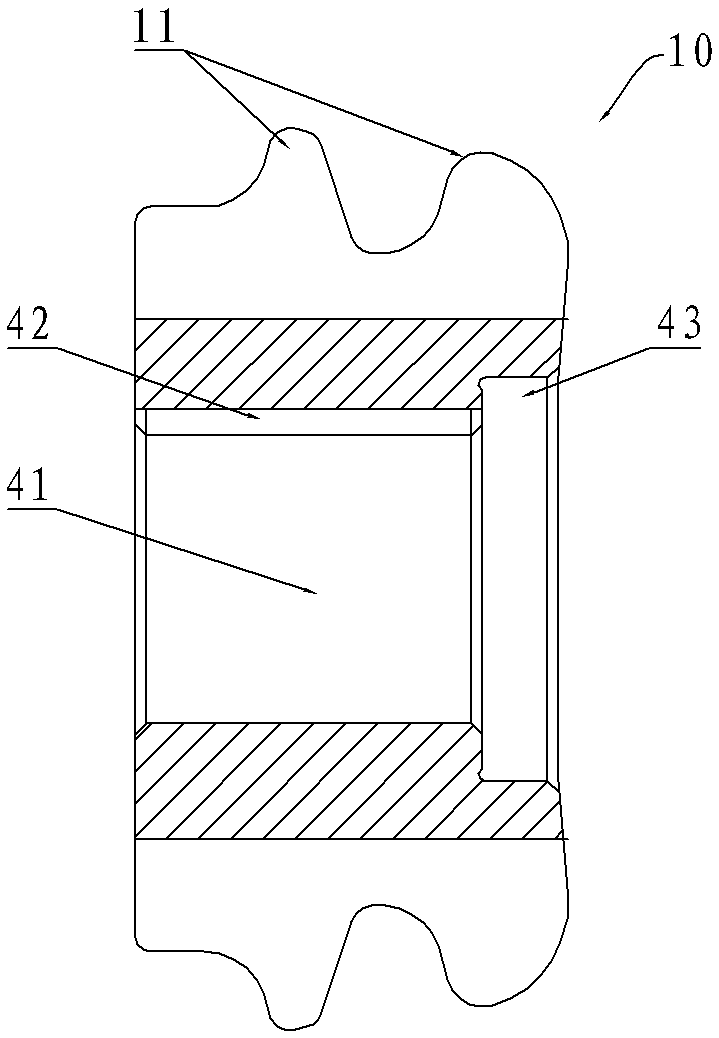

[0019] See Figure 3 ~ Figure 7 , a milling cutter for processing the fir tree-shaped blade root of a steam turbine blade, which includes a front tenon tooth milling cutter 10 and a rear tenon tooth milling cutter 20, the front tenon tooth milling cutter 10 is provided with a front tenon tooth 11 on the outer periphery, and a rear tenon tooth milling cutter Milling cutter 20 outer periphery is provided with, and the tooth shape of front tenon tooth 11, the tooth shape of back tenon tooth 21 is to determine split boundary at the second tooth 32 addendum places and Thus, the split boundary 33 extends axially and tangentially respectively to the theoretical tooth profile of the front tenon tooth 34 and the theoretical tooth profile of the rear tenon tooth 35 formed after splitting.

[0020] The tooth shape of the front tenon tooth and the tooth shape of the rear tenon tooth can also be the fixed value envelope tooth shape according to the theoretical tooth shape of the front teno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com