A high hardness, high toughness machining insert for difficult-to-cut materials

A high-toughness, difficult-to-cut technology, applied in the field of metal cutting tools, can solve the problems of difficult-to-machine efficiency reliability and timely and effective chip removal, affect the processing quality of the workpiece surface, and chip removal can scratch the surface of the workpiece. Longer service life, improved workpiece accuracy, and reliable chip breaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

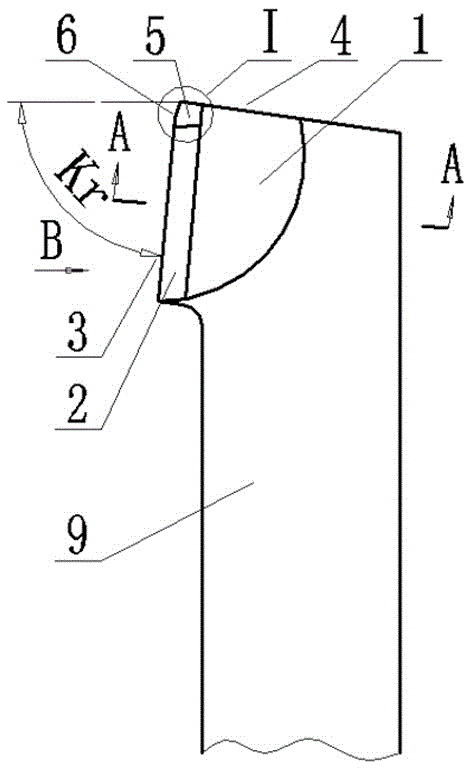

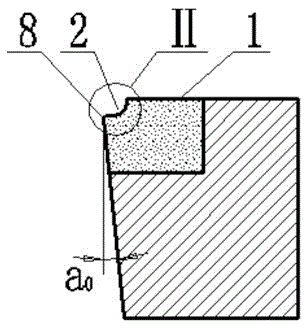

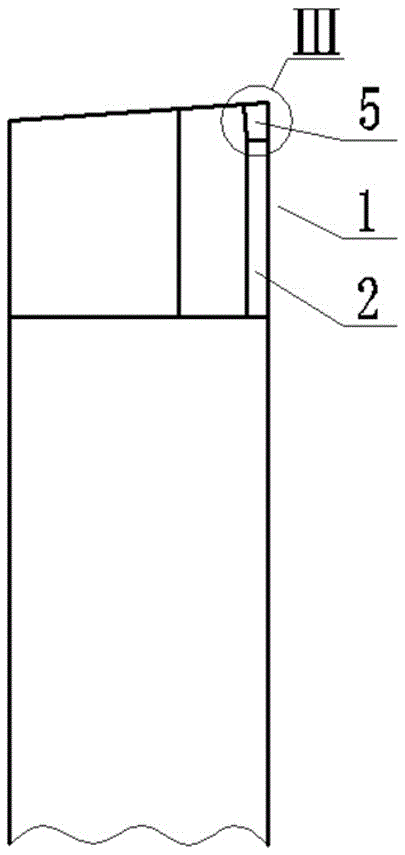

[0023] The hardness of 9Cr3Mo after quenching reaches HRC60~68, the blade is inlaid with YT726 cemented carbide on the handle 9, and the rake angle of the blade is γ o =0° and chamfering, back angle is α o =5°, the main declination angle is K r =85°, cutting edge inclination angle is λ s =0°; the rake face 1 of the insert is set with a rake angle of 0° and a parallel linear arc-shaped main chipbreaker 2 with a width of 2.5mm and a depth of 1.5mm. The main cutting edge 3 of the main chipbreaker 2 and the auxiliary The tool tip formed by the cutting edge 4 is set along the axial direction of the main chip breaker 2 with a length of 1.5mm and an auxiliary rake angle of -5°γ o ’Auxiliary chip breaker 5; The main cutting edge 3 of the main chip breaker 2 is provided with a secondary rake angle of -20°γ o ” and a negative chamfer 8 with a width of 0.15 mm; the main cutting edge 3 at the tool tip is provided with a transitional edge 6 with an angle of 165° counterclockwise and 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com