A horizontally stable automatic stress measurement drilling machine and its working method

A working method and level-stable technology, applied in measuring/indicating equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency, long test time, and affecting stress test results, and achieve convenient and accurate operation and convenient positioning accuracy , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

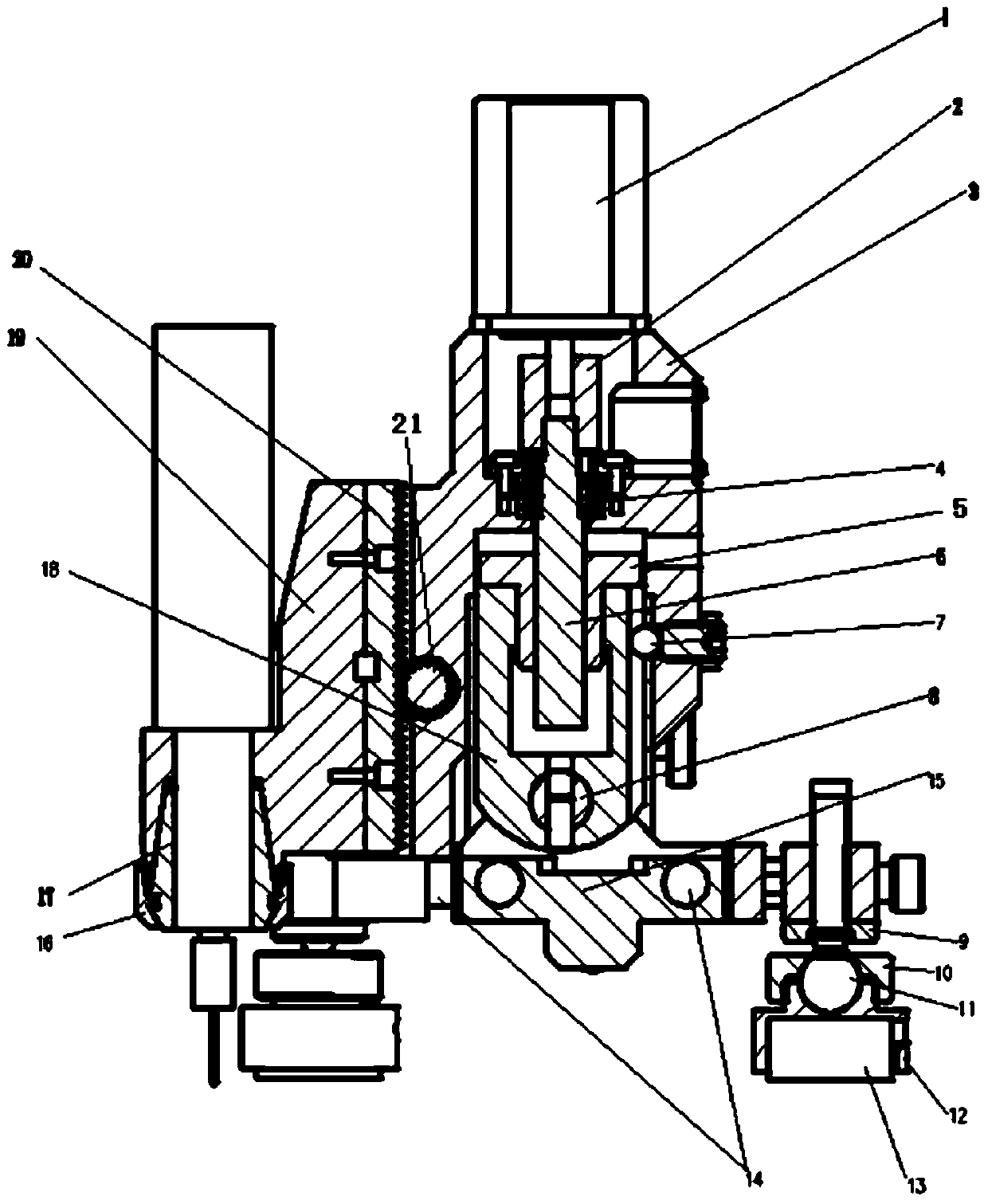

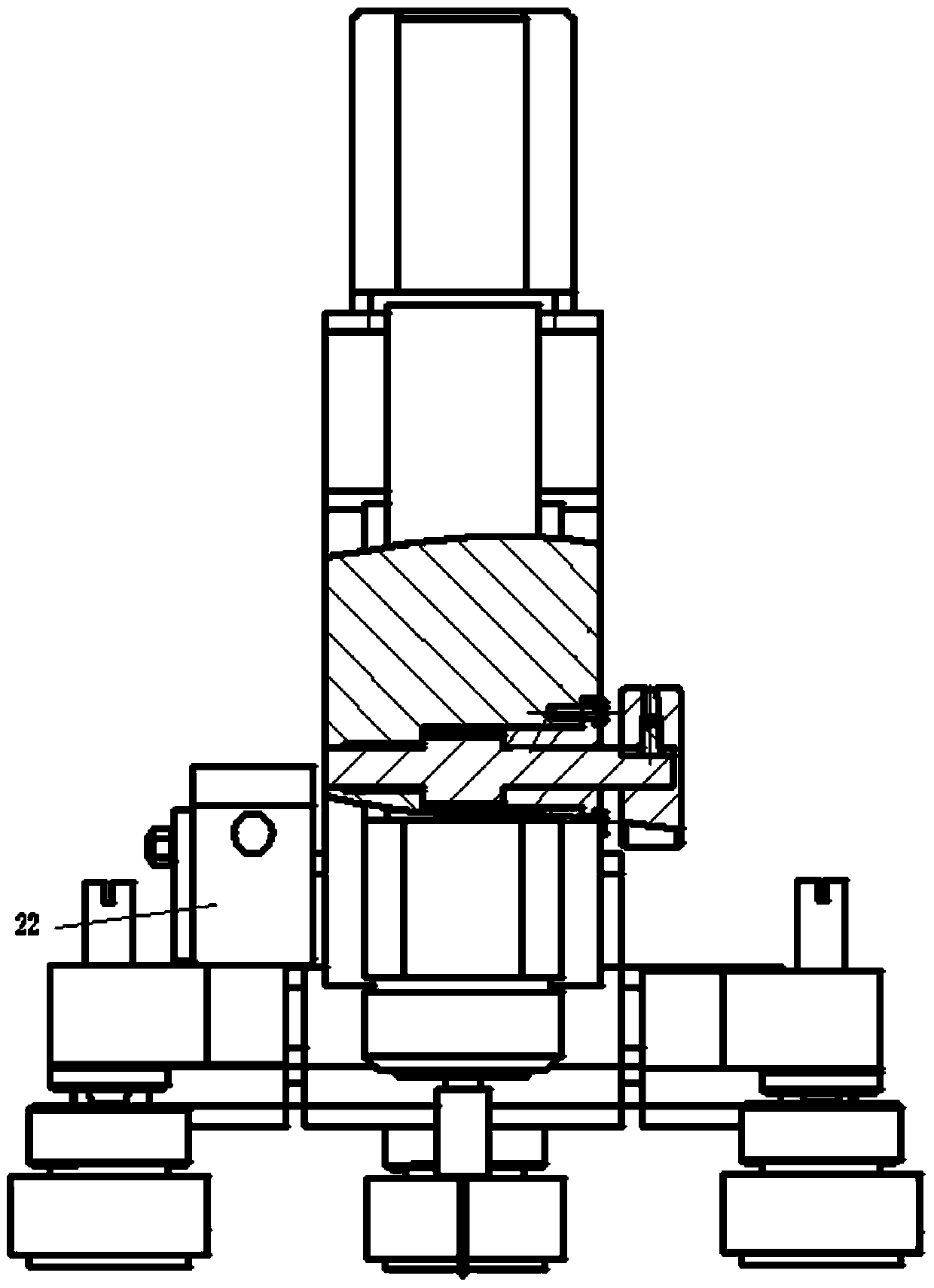

[0047] A horizontally stable automatic stress measurement drilling machine, comprising a base and a gun drill part erected by the base, the gun drill part including a driving device and a gun drill 27 driven by the driving device;

[0048] The base also includes at least three legs 28 for adjusting the angle, which are arranged on the bottom of the rack 29;

[0049]The support foot 28 includes a ball stud 11 connected to the rack 29, a compression nut 10, a magnetic base 12 and a magnetic chuck 13, and the ball stud 11 is connected by a lock nut 9 arranged at the bottom of the rack 29 , the ball head of the ball head rod 11 cooperates with the compression nut 10 and the magnetic base 12 so that the magnetic base 12 is arranged at multiple angles; a second spirit level 33 is arranged on the horizontal plane of the base.

Embodiment 2

[0051] A horizontally stable automatic stress measurement drilling machine as described in Embodiment 1, the difference is that the plane of the top end of the gun drill 27 is perpendicular to the axial direction of the gun drill 27, and at the top of the gun drill 27 The plane is provided with a first spirit level 34 .

Embodiment 3

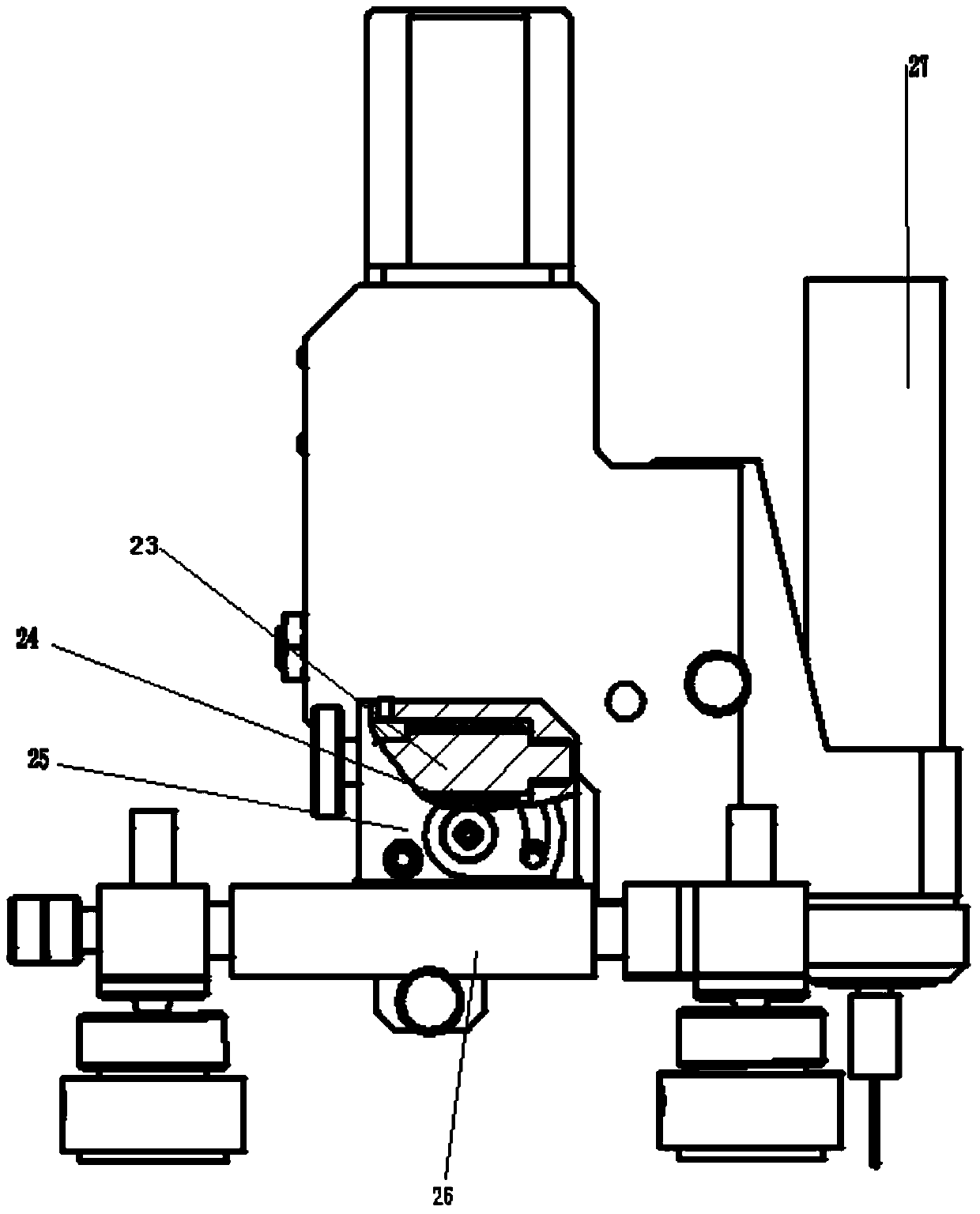

[0053] A horizontally stable automatic stress measurement drilling machine as described in Embodiments 1 and 2, the difference is that the gun drill 27 is connected to the driving device through the gun drill base 19 . The gun drill base 19 is connected with the driving device through a rack 20 and a positioning gear 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com