Blown film cooling method and device based on air source dynamic distribution

A technology of dynamic distribution and blown film, which is applied in the field of blown film cooling, can solve the problems of uneven film thickness, poor film transparency, uneven air outlet, etc., achieve flexible and convenient application, improve film quality, and simple device principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

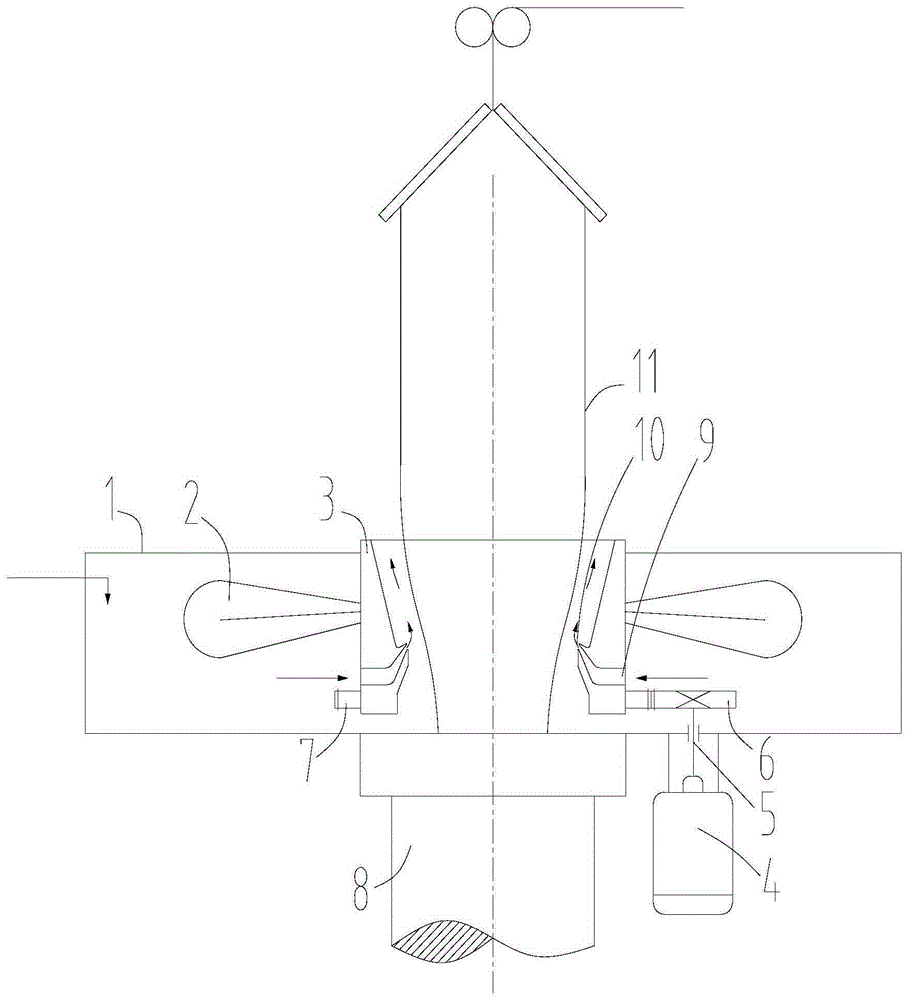

[0026] In this embodiment, a blown film cooling device based on the dynamic distribution of air sources includes an air ring body assembly and a drive assembly, such as figure 1 As shown, the blown film cooling device based on the dynamic distribution of air source is placed above the die head 8. The air ring body assembly includes the outer ring 1 of the air ring, the distribution fan 2, and the outer ring 3 of the air outlet. The drive assembly includes the drive motor 4, Power output shaft 5, driving gear 6 and driven gear 7. The driven gear is connected with the distribution fan, the driving motor drives the driving gear to rotate through the power output shaft, and the driving gear meshes with the driven gear to drive the distribution fan to rotate.

[0027] In the air ring body assembly, the air inlet 9 is arranged on the outer wall of the outer ring of the air outlet, the air outlet 10 is arranged on the inner wall of the outer ring of the air outlet, and several throug...

Embodiment 2

[0035] In this embodiment, a blown film cooling method based on the dynamic distribution of air source is realized through the device described in Embodiment 1. The rotation of the distribution fan is used to generate negative pressure, and the cold air is sucked into the annular air cavity, and due to the rotation of the distribution fan , the cold air forms a cooling airflow evenly distributed in the circumferential direction at the annular air outlet, and the cooling airflow blows to the surface of the film bubble, and the cooling airflow is evenly distributed from the air source to cool the film bubble evenly. Wherein, the cooling airflow at the cooling air ring is a rotating annular airflow, and the annular airflow blows towards the outer surface of the film bubble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com