Two-hand molding line

A mold line and two-hand technology, applied in household components, combined devices, applications, etc., can solve the problems of process equipment hindering technical exchanges, limiting the speed of technology improvement, and unstable production technology, so as to improve service life and save power consumption. , the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

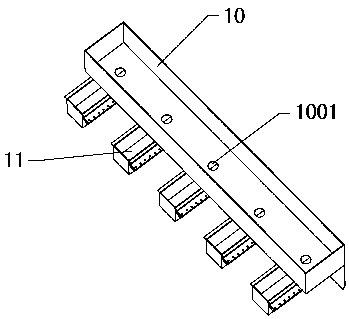

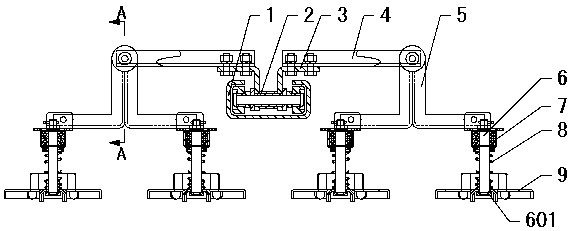

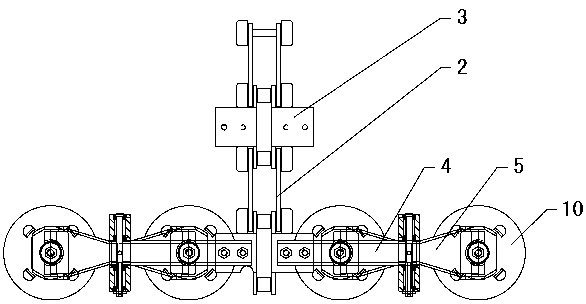

[0028] Figure 1~8 It is the best embodiment of the two-hand mold line, and the following is combined with the attached Figure 1~8 The present invention will be further described.

[0029] refer to figure 1 , the two-hand mold line includes a chain guide seat 1, a transmission chain 2, a fixed arm 4 and a swing arm 5, the transmission chain 2 is slidably arranged in the guide groove of the chain guide seat 1, and the two sides of the chain guide seat 1 are respectively provided with fixed Arm 4, the inner end of fixed arm 4 is fixedly connected with transmission chain 2, and the outer end of each fixed arm 4 is rotatably connected with two swing arms 5, and the bottom of swing arm 5 is connected with hand mold holder 9 respectively. Each chain of the original production line can hang two hand mold holders, and after the modified production line chain can hang four hand mold holders, under the condition of keeping the speed constant, the output of the single-hand mold line c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com