Hollow container manufacturing method

A container manufacturing and hollowing technology, applied in the direction of hollow objects, other household appliances, household appliances, etc., can solve the problems of reducing scrap rate, large stretching of barrel blanks, precipitation of bisphenol A, etc., to avoid wall deformation and uniform force , the effect of stretching small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

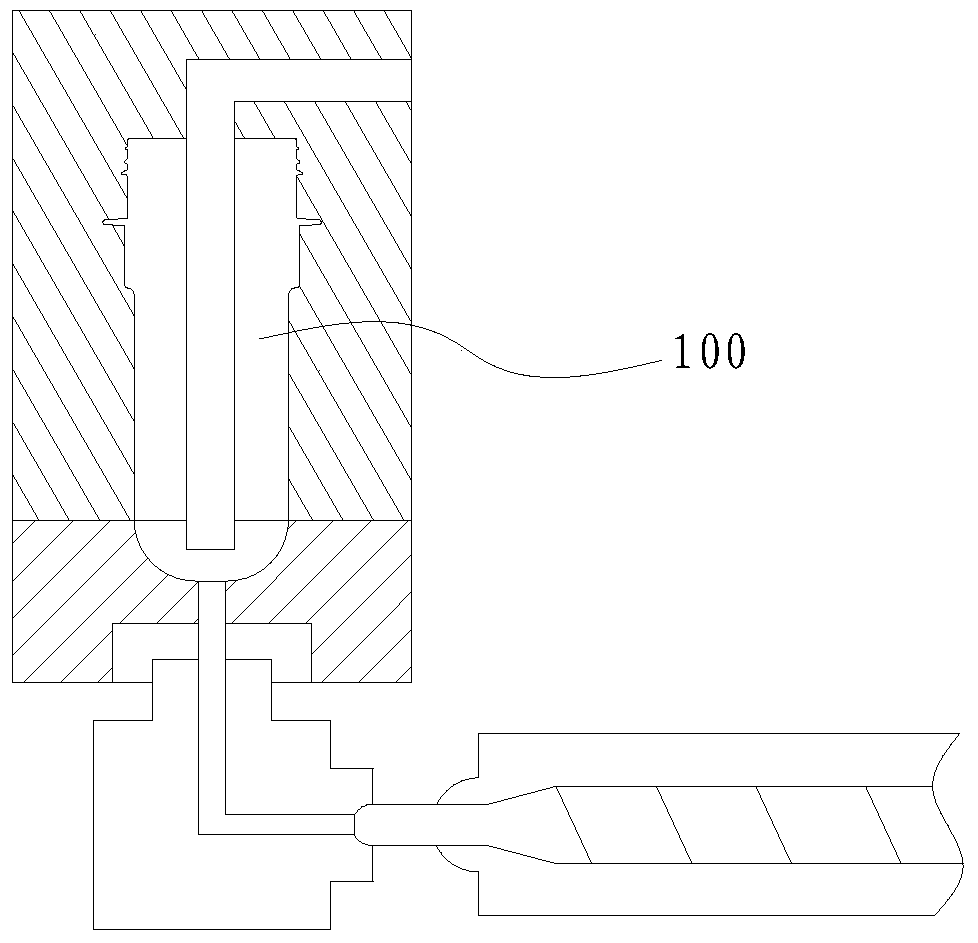

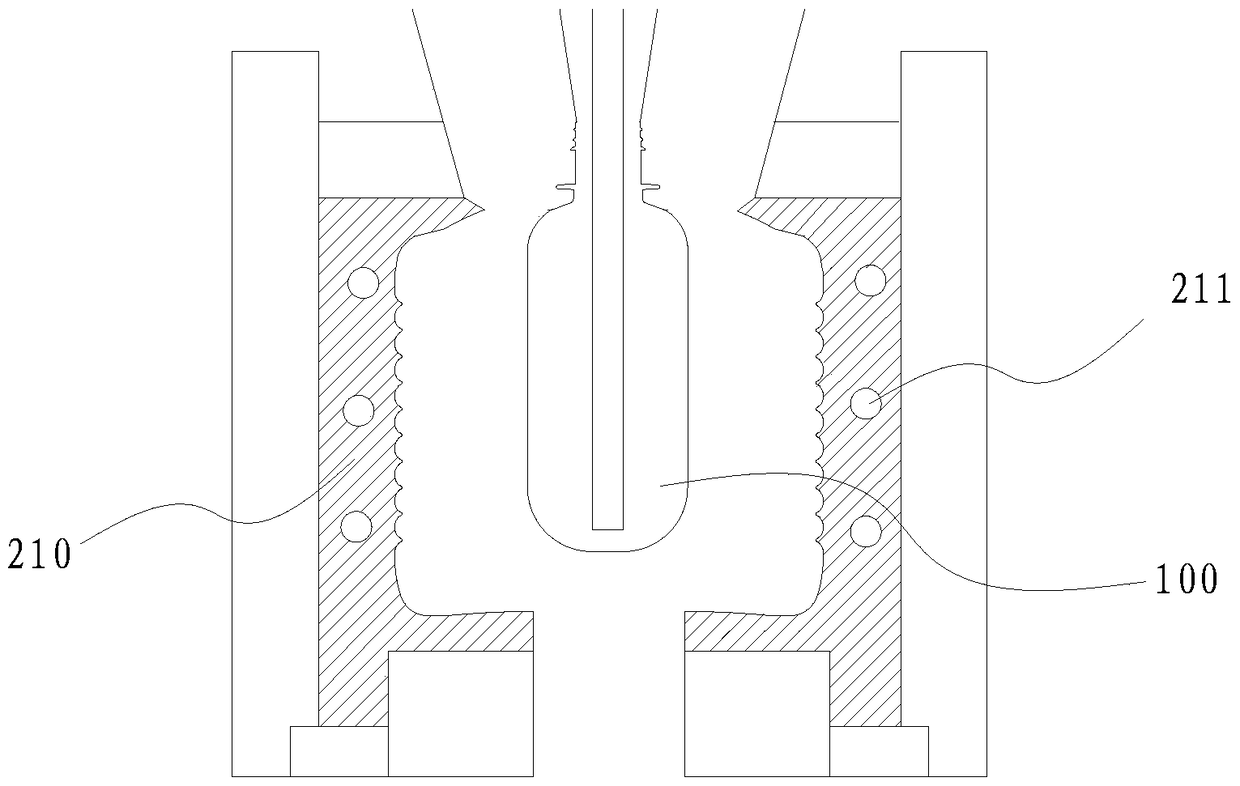

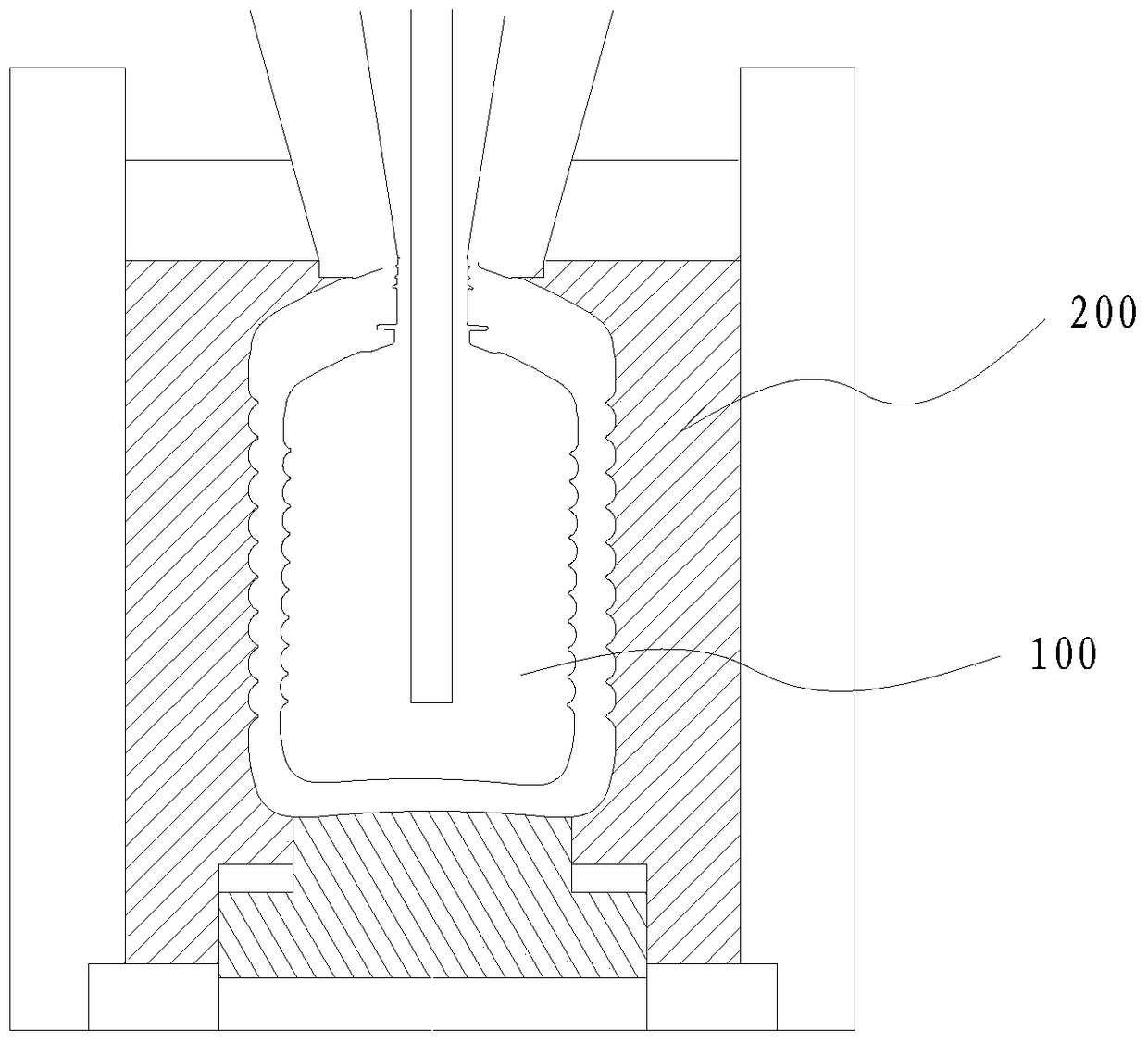

[0037] As shown in the figure, taking the manufacture of a hollow container blank 100 as an example, the first end of the blank 100 is the blank top 110 (the opening of the bucket), and the second end of the blank 100 includes the blank middle 120 (the barrel of the bucket) and Blank bottom 130 (the bottom of the bucket), the blank middle 120 is located between the blank top 110 and the blank bottom 130, the blank top 110 is provided with an opening, can blow air to the blank 100, the thickness of the blank middle 120 is 0.1mm-0.3mm, the container Less material is used, the production and use costs are low, and it is suitable for one-time use, avoiding sanitary hazards caused by recycling.

[0038] Moreover, the middle part 120 of the billet is provided with a wrinkled part. Because the wall thickness is very thin, the folded part can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com