Blood type detection card filling machine

A detection card and filling machine technology, applied in packaging, transport packaging, transportation and packaging, etc., can solve the problems of low production efficiency, slow production speed, and unstable product quality of blood type cards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

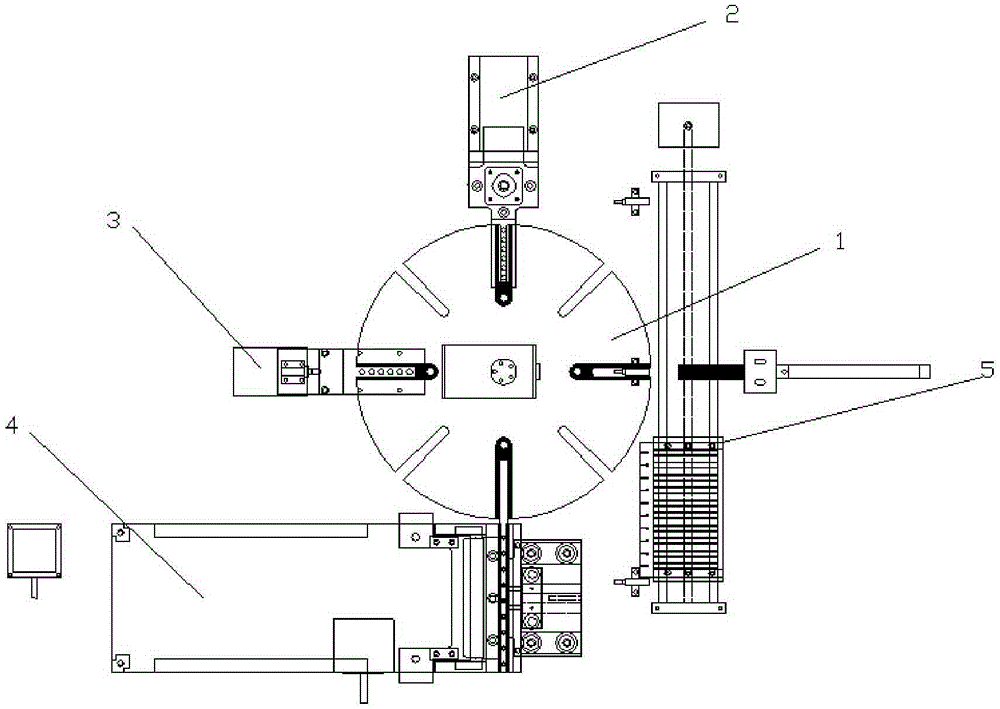

[0057] The blood type card filling machine provided by the present invention includes a turntable mechanism 1 and an automatic card feeding structure 5 as a filling and sealing mechanism, a liquid filling mechanism 2, a powder filling mechanism 3 and a heat sealing mechanism 4. The overall structure of the blood type card filling machine Schematic such as figure 1 shown;

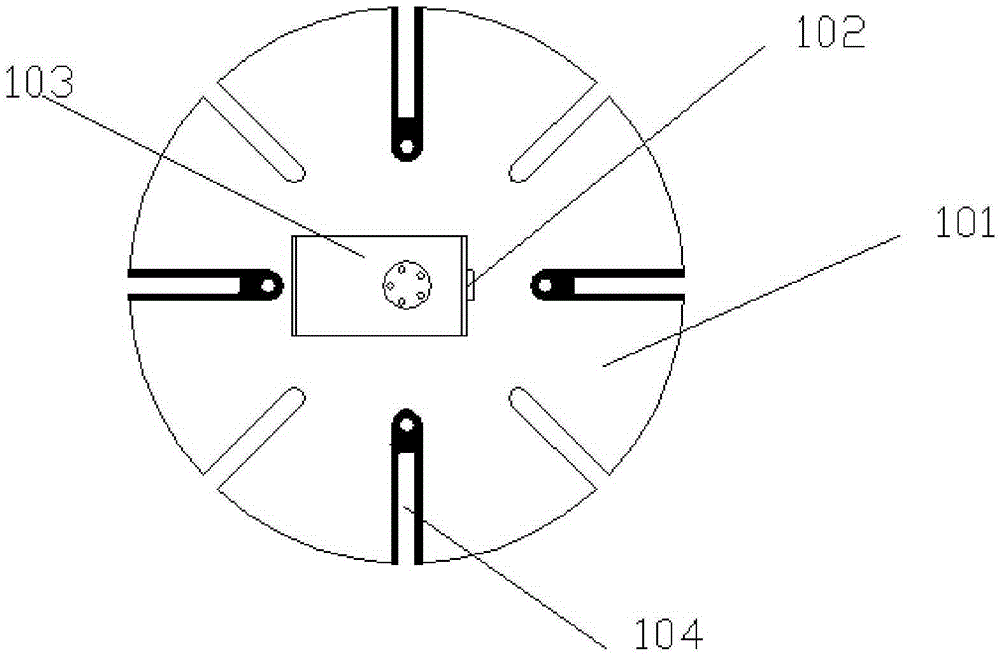

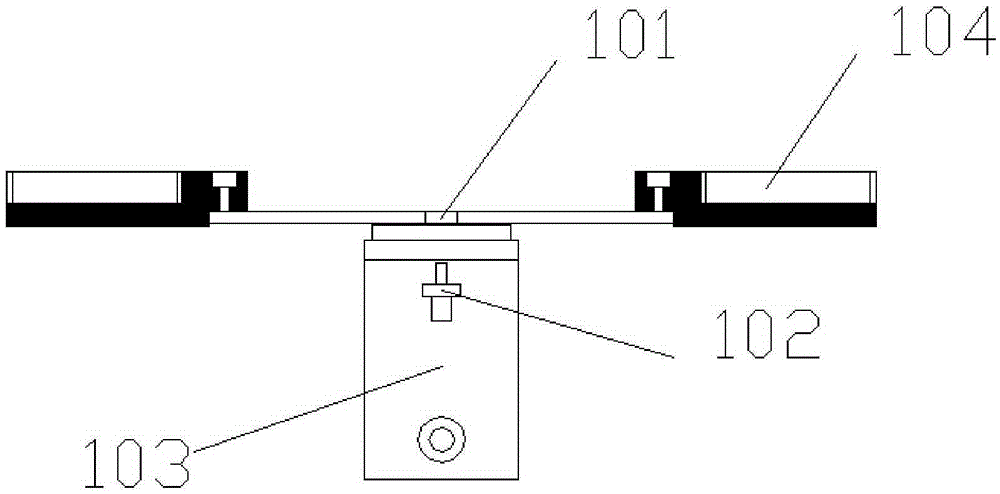

[0058] The turntable mechanism includes a turntable 101, a photoelectric sensor 102, a stepper motor 103 for the turntable, a card slot 104,

[0059] The turntable is circular, and its central axis is connected to the power output shaft of the stepping motor. The stepping motor of the turntable is used to drive the turntable to rotate. On the turntable, 4N radial grooves penetrating the body of the turntable are evenly distributed along the circumference of the turntable. The card slot is installed in a radial slot for holding the blood type card to be filled; the photoelectric sensor 102 is installed under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com