Automatic control system for gathering and laying of cables

An automatic control system, a technology for receiving and arranging wires, which is applied in the direction of cable/conductor manufacturing, conductor/cable supply device, circuit, etc., and can solve problems such as cumbersome process, decreased precision, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

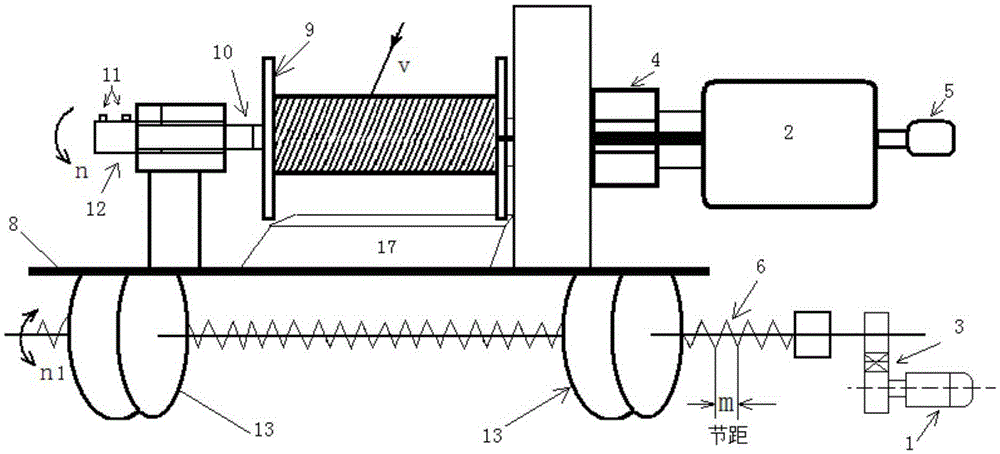

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

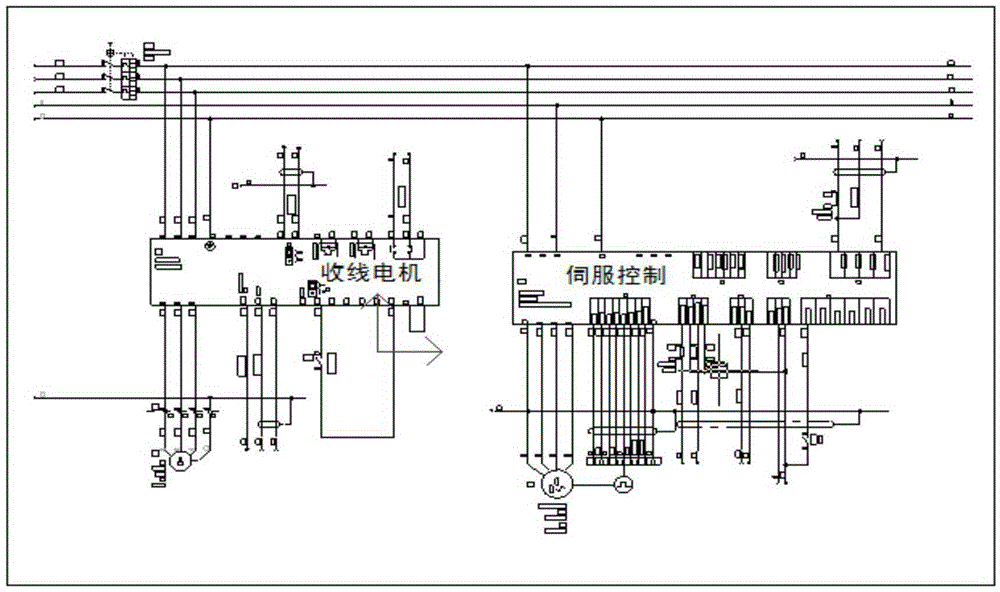

[0025] Automatic cable take-up and discharge control system, the system is mainly composed of a main controller, a cable take-up servo control unit and a take-up control unit. The wire take-up control unit is mainly used to control the operation of the wire take-up mechanism, and the wire arranging servo control unit is mainly used to control the operation of the wire arranging mechanism. The wire arranging servo control unit is composed of a servo motor and a servo driver, and the wire take-up control unit is composed of a wire take-up motor 2 and a frequency converter.

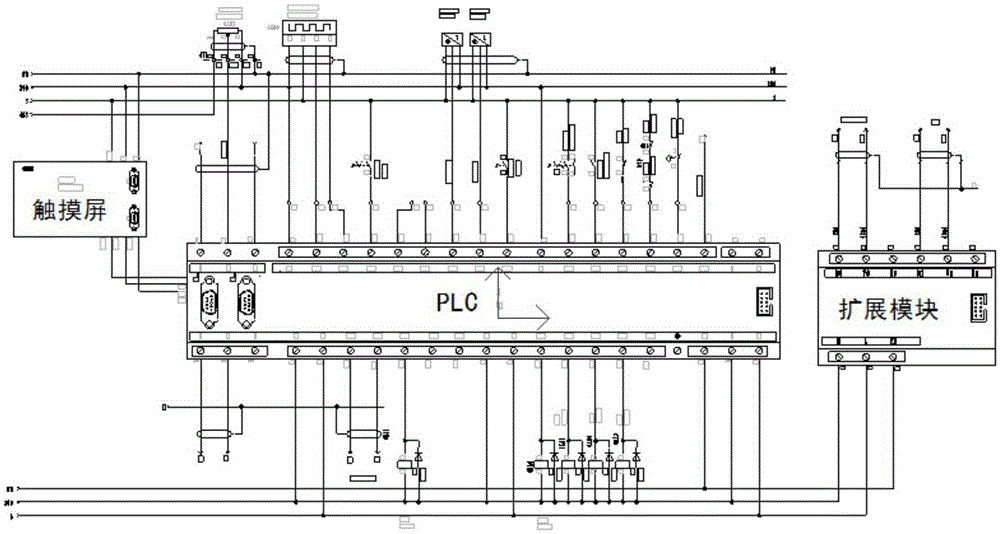

[0026] The controller selected in this embodiment is a PLC controller, and the ports of the PLC are respectively connected to a servo driver and a frequency converter for sending and transmitting instructions. The servo motor is controlled by a servo driver, and the wire take-up motor is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com