Catalytic hydrogenation and decoloration method of 1,4-butanediol

A technology for catalytic hydrogenation and butanediol, applied in chemical instruments and methods, organic chemistry, preparation of hydroxyl compounds, etc., can solve the problem that the appearance quality and hue index cannot meet the requirements of qualified products, the quality of products is reduced, and the quality of products is reduced. Downgrade and other problems, to achieve the effect of increasing the product quality rate, reducing product chroma, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

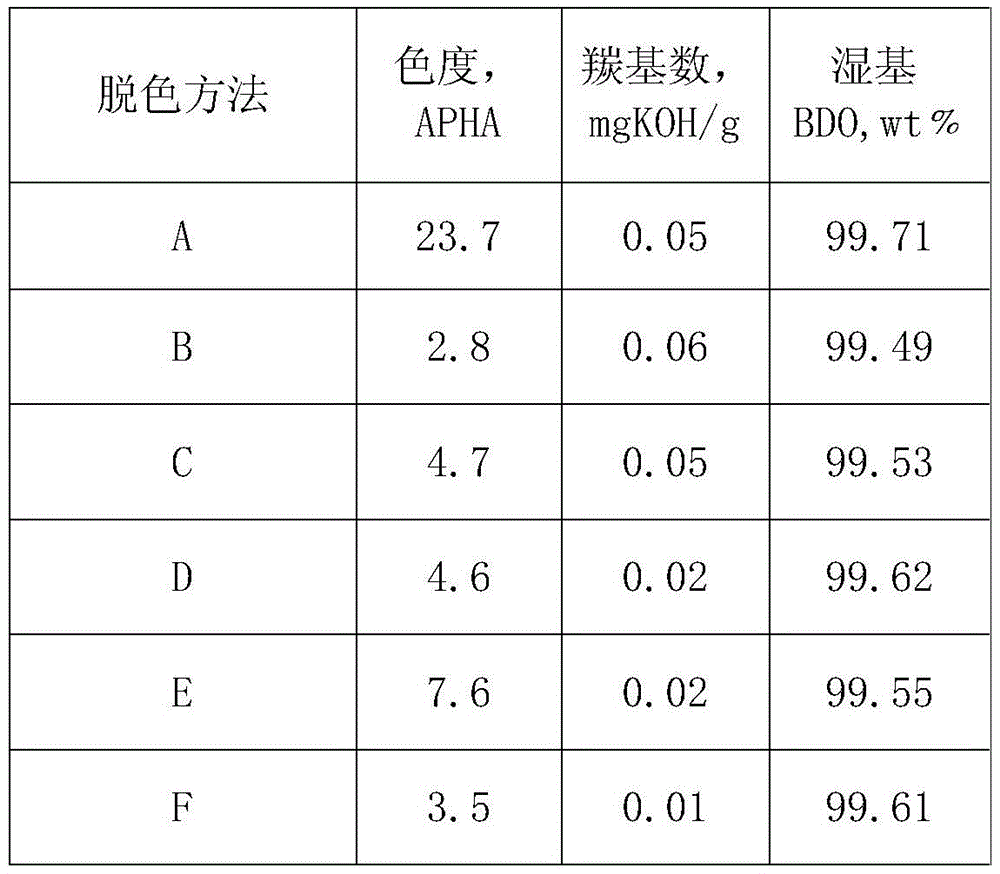

[0014] Weigh 2g of Pd-C catalyst (loading capacity 0.5%) and add it into the reactor; weigh 200mL of BDO (number sample A) and add it into the reactor. H was introduced into the reactor 2 Increase the pressure to 2MPa, heat to 110°C and stir, react for 3 hours, stop stirring, filter to obtain decolorized BDO, and use a colorimeter to analyze the color of decolorized BDO (sample number B). The analysis data of samples A and B are compared in Table 1.

Embodiment 2

[0016] Weigh 2g of loaded Pd molecular sieve catalyst (loading capacity 5%), add it to the reactor, measure 200mL of BDO (number sample A) and add it to the reactor, and feed H into the reactor. 2 Increase the pressure to 2MPa, heat to 90°C and stir, react for 3 hours, stop stirring, filter to obtain decolorized BDO, use a colorimeter to analyze the color of decolorized BDO (sample number C), and compare the analysis data of sample C in Table 1.

Embodiment 3

[0018] Weigh 3g platinum loaded Al 2 o 3 Catalyst (loading capacity 10%) was added to the reactor, and 300mL of BDO (number sample A) was measured and added to the reactor, and H was introduced into the reactor. 2 Increase the pressure to 3MPa, heat to 80°C and stir, react for 3 hours, stop stirring, filter to obtain decolorized BDO, use a colorimeter to analyze the color of decolorized BDO (sample number D), and compare the analysis data of sample D in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com